Golf Mk3

|

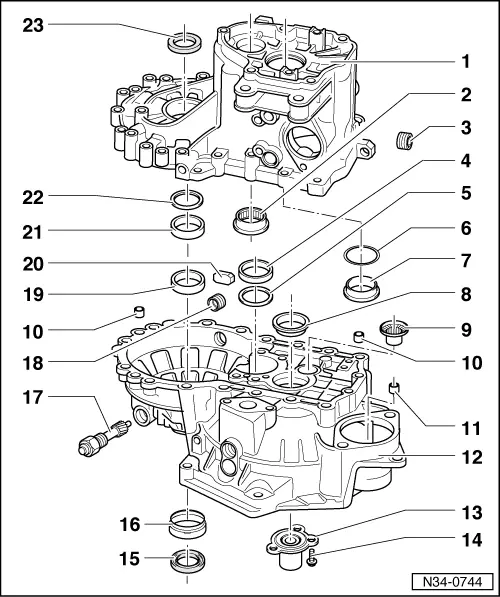

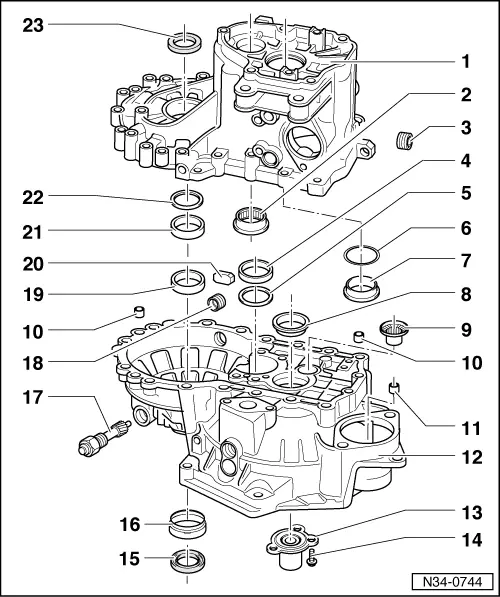

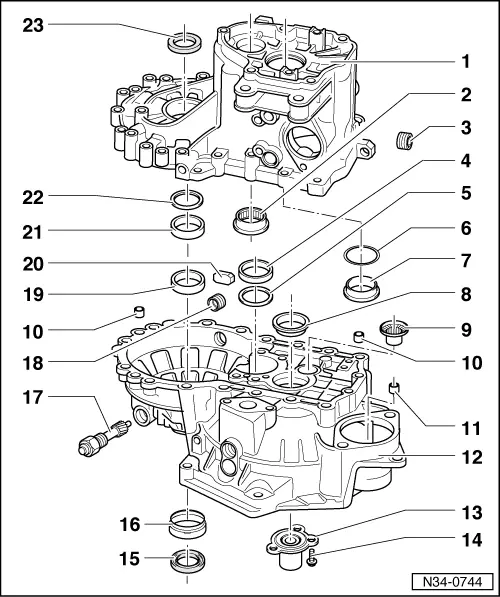

Servicing gearbox housing and clutch housing

Servicing gearbox housing and clutch housing

|

|

|

|

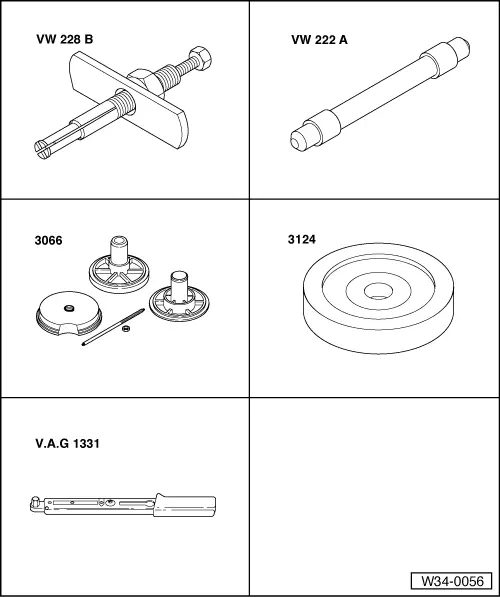

Special tools and workshop equipment required

|

|

|

|

Special tools and workshop equipment required

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

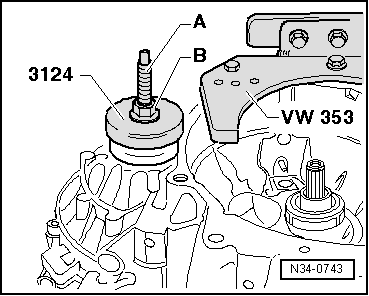

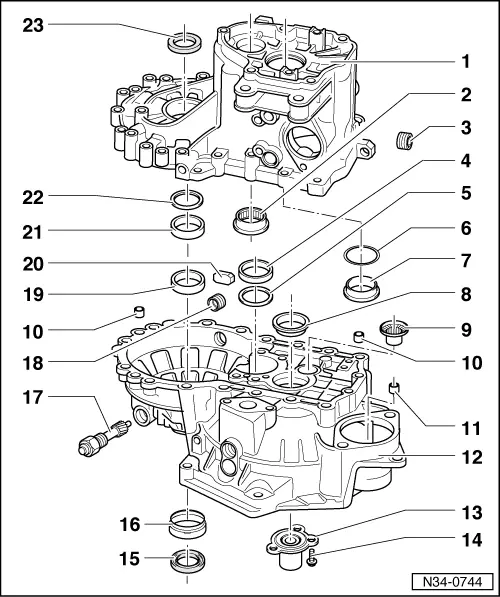

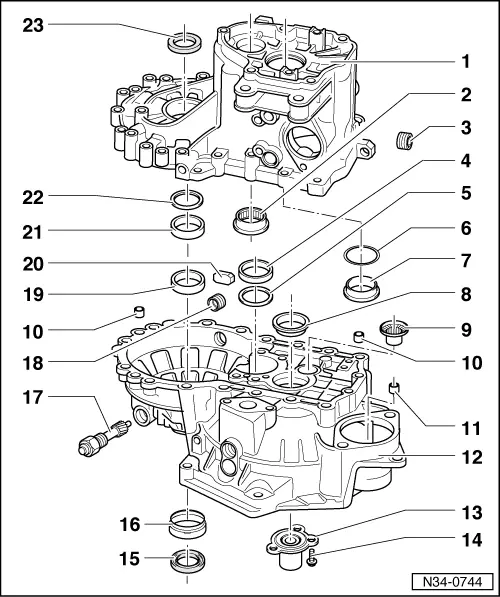

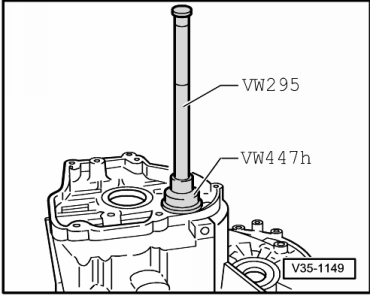

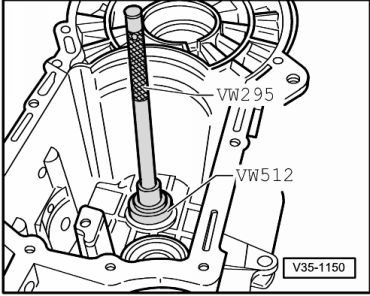

→ Fig.1 Knocking-out needle roller bearing. |

|

|

|

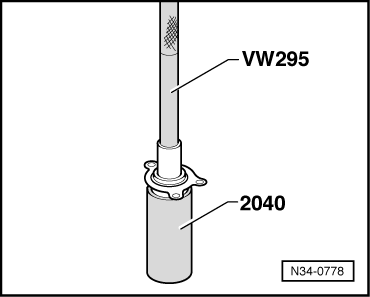

→ Fig.2 Knocking needle roller bearing in onto stop |

|

|

|

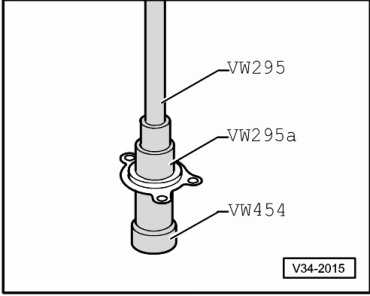

→ Fig.3 Knocking oil seal out of guide sleeve. |

|

|

|

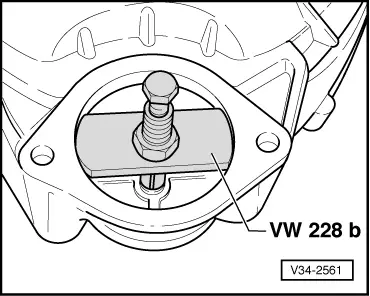

→ Fig.4 Knock oil seal into the guide sleeve onto stop. |

|

|

|

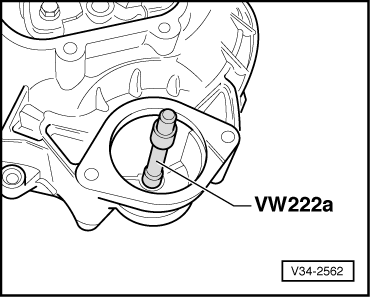

→ Fig.5 Pulling out starter bush. |

|

|

|

→ Fig.6 Knocking in starter bush. |

|

|

|

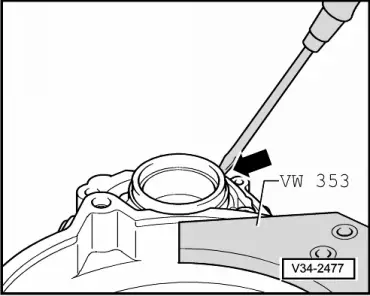

→ Fig.7 Lever out sleeve with screwdriver |