Golf Mk3

Note

Note

|

| 1 - | Selector lever |

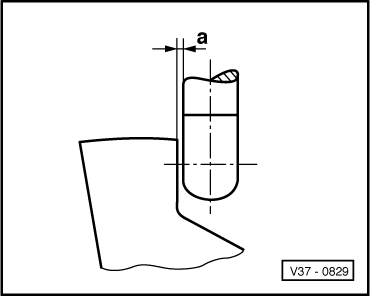

| q | Assembling → Fig. |

| 2 - | Indicator lighting |

| q | Securing indicator lighting connector (one-piece solenoid with wiring harness) → Fig. |

| q | In right-hand drive vehicles, there is an additional contact that prevents the engine from being started when locking button on “selector lever handle” is pressed. |

| 3 - | Spring |

| 4 - | Push rod |

| q | Grease sliding surfaces |

| 5 - | Guide sleeve |

| q | Fit after installing push rod. |

| 6 - | Set screw |

| q | Always renew |

| q | To remove set screw, remove selector lever lock solenoid -N110- and indicator lighting. Clamp set screw in vice and loosen by turning selector lever. |

| q | Insert with locking fluid -AMV 185 101 A1- |

| 7 - | Selector lever lock solenoid -N110- |

| q | May be one part together with wiring harness or harness may be separate part |

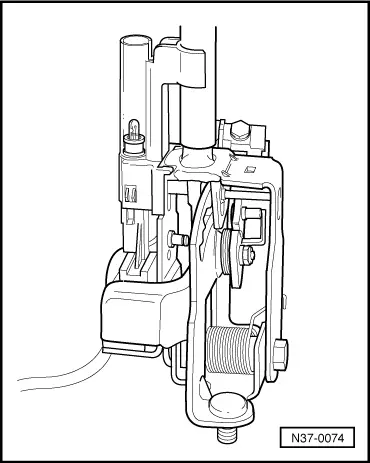

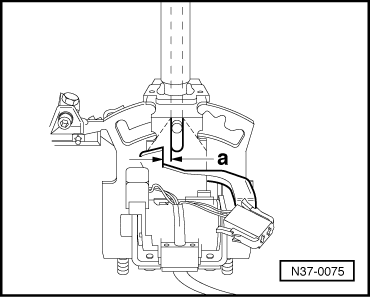

| q | Adjusting → Fig. |

| q | Functional check → Fig. |

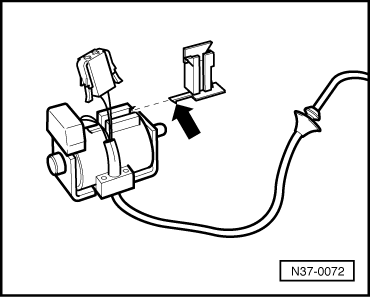

| q | Securing wiring harness to selector bracket (selector lever lock solenoid -N110- with wiring harness) → Fig. |

| q | Securing wiring harness to selector lever lock solenoid -N110- and indicator lighting → Fig. |

| q | Securing indicator lighting connector → Fig. |

| q | Can be checked in electrical check → Chapter and in measured value block → Chapter |

| 8 - | Bolt, 3 Nm |

| q | Qty. 2 |

| q | Insert with locking fluid -AMV 185 101 A1- |

| 9 - | Nut, 5 Nm |

| q | Always renew |

| 10 - | Washer |

| 11 - | Locking lever |

| q | For ignition key removal lock. |

| q | Adjust together with locking cable → Chapter. |

| 12 - | Spring |

| q | Hook into hole in detent segment |

| 13 - | Support bracket |

| q | For locking cable |

| q | Removing and installing locking cable → Chapter |

| q | Adjusting locking cable → Chapter |

| 14 - | Spring |

| q | For locking pin |

| 15 - | Detent segment |

| q | Assemble selector lever before installing in selector bracket → Fig. |

| 16 - | Locking pin |

| q | with holder |

| 17 - | Hexagon socket head bolt, 6 Nm |

| 18 - | Bolt, 6 Nm |

| 19 - | Washer |

| 20 - | Spring |

| q | Insert in selector lever together with lever → Item |

| 21 - | Lever |

| q | For locking in selector lever position “N” or “P” |

| q | Adjusting → Fig. |

| 22 - | Bush |

| 23 - | Nut, 10 Nm |

| q | Always renew |

| 24 - | Flange bolt |

| q | Grease shank |

|

|

|

|

|

|