|

Servicing valve gear

Checking hydraulic bucket tappets

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

◆ Feeler gauge

-

◆ Wood or plastic wedge

Notes:

-

◆ Renew defective tappet complete (cannot be adjusted or repaired).

-

◆ Irregular valve noises when starting engine are normal.

Test sequence

-

‒ Start engine and run until the radiator fan has switched on once.

-

‒ Increase engine speed to about 2500 rpm for 2 minutes.

If the hydraulic tappets are still noisy, locate defective tappets as follows:

-

‒ Remove cylinder head cover.

-

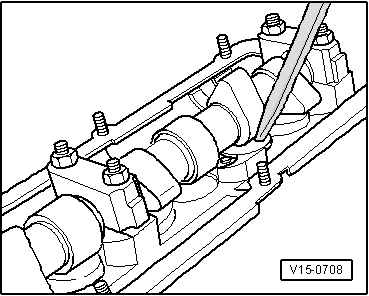

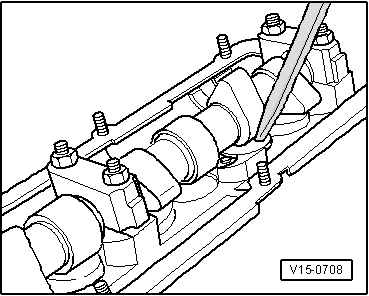

‒ Rotate crankshaft clockwise, until cam of the tappet to be checked is pointing upwards.

-

‒ Determine play between cam and bucket tappet.

-

‒ If the play is in excess of 0.1 mm, renew bucket tappet. If the play is less than 0.1 mm or no play, proceed with check as follows:

|