Golf Mk3

|

Servicing valve gear

Removing and installing camshafts

Removing

=> Repair group 28; Motronic injection and ignition system; Servicing ignition part

|

|

|

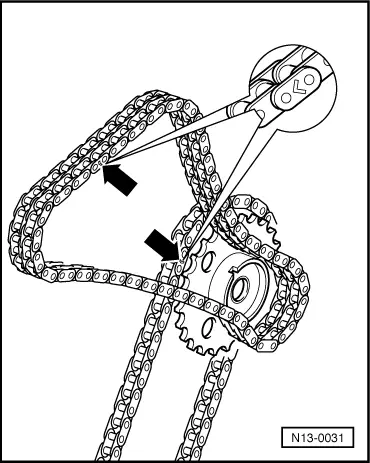

→ Note: Only counter-hold camshaft with 24 mm OJ spanner -arrow-. The camshaft jig 3268 must not be in place when tightening or loosening the chain sprockets.

|

|

|

Notes:

|

|

|

|

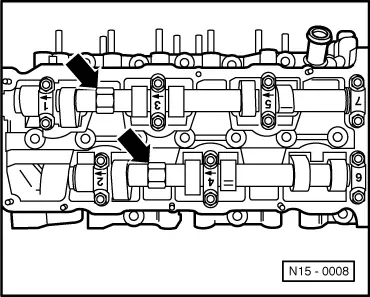

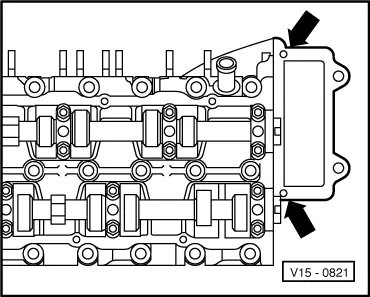

→ Camshaft cylinder bank 1, 3 and 5

Camshaft cylinder bank 2, 4 and 6

Installing

Notes:

|

|

|

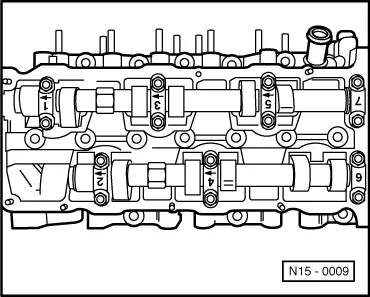

Camshaft cylinder bank 1, 3 and 5

Camshaft cylinder bank 2, 4 and 6

|

|

|

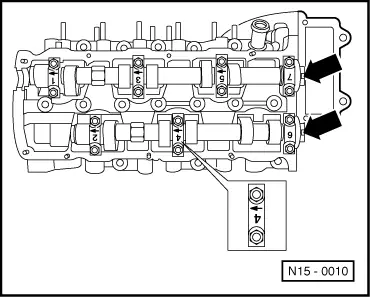

Note: With the cylinder head installed the holes in the cylinder head gasket are only half visible.

Notes:

|