Golf Mk3

| Repairing drive shaft |

| Drive shafts on vehicles with Plus running gear have shorter and finer splines on the outer joint. A 12-point nut is used to secure to wheel bearing. |

| The splines of the outer joint and the wheel hub are bonded with locking fluid -D 185 400 A2-. |

| Removing and installing drive shaft for vehicles with Plus running gear → Chapter. |

Note

Note| t | Quantity of grease for vehicles up to 48 kW: 90 g G 6.3 on outside and inside |

| t | Quantity of grease for vehicles with 55 kW and above: |

| t | Outside: 110 g G 6.3 |

| t | Inside: 120 g G 6.3 |

| t | Greasing outer joint: press half of the grease into the joint and the other half evenly into the bellows. |

| t | Greasing inner joint: press half of the grease into the joint from both sides and the other half evenly into the bellows. |

| t | Regrease joint if required when renewing boot. |

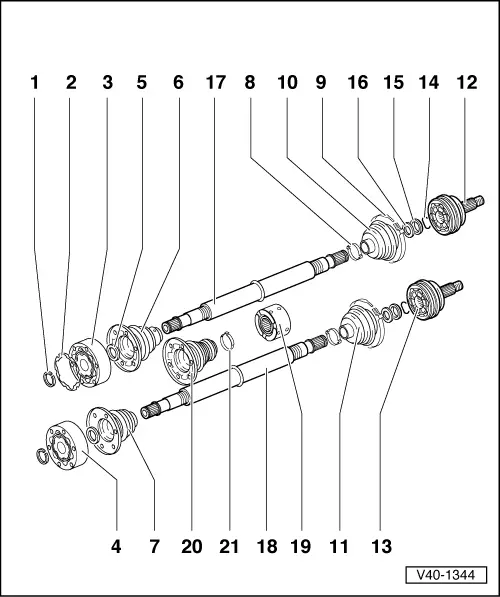

| 1 - | Retaining ring |

| q | Renew |

| q | Remove and install with circlip pliers -VW 161 A-. |

| 2 - | Gasket |

| q | Renew: Pull off protective foil and stick onto joint. Only 100 mm Ø constant velocity joints. |

| Modification |

| q | As of 08.93 also on constant velocity joints with 90 mm Ø. |

| 3 - | Inner constant velocity joint 100 mm Ø for vehicles with output of 55 kW and above |

| q | Renew only complete. |

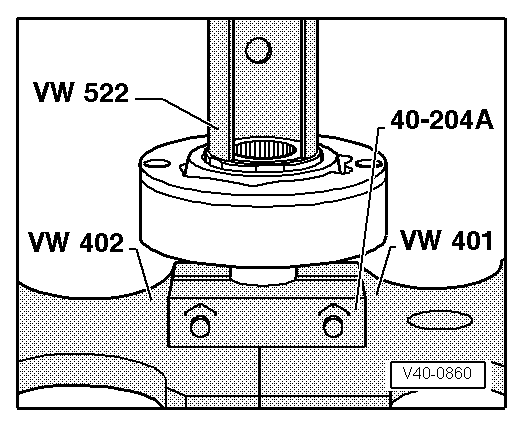

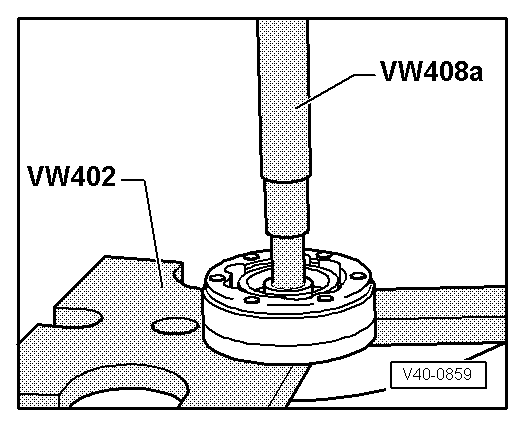

| q | Pressing off → Fig.. |

| q | Pressing on → Fig.. |

| q | Greasing → Chapter |

| q | Checking → Chapter |

| 4 - | Inner constant velocity joint 94 mm Ø for vehicles with output up to 48 kW |

| q | Pressing off → Fig.. |

| q | Pressing on → Fig.. |

| q | Greasing → Chapter |

| q | Checking → Chapter |

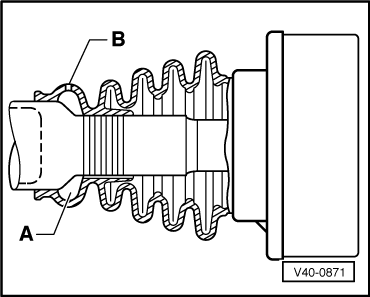

| 5 - | Dished spring |

| q | Splines in inner diameter. |

| q | Installation position: larger Ø (concave side) contacts constant velocity joint. |

| 6 - | Joint protective boot for 100 mm Ø constant velocity joint |

| q | With vent hole |

| q | Check for splits and chafing. |

| q | Installation position for left shaft → Fig. |

| q | Installation position for right shaft → Fig.. |

| q | Coat cap with D3. |

| q | Drive off with drift. |

| 7 - | Joint protective boot for 94 mm Ø constant velocity joint |

| q | Check for splits and chafing. |

| q | Drive off with drift. |

| 8 - | Clamp |

| q | Renew |

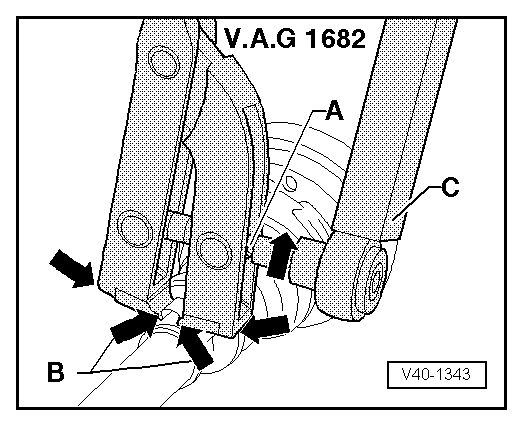

| q | Tensioning → Fig. and → Fig.. |

| 9 - | Hose clip |

| q | Renew |

| q | Tensioning → Fig. and → Fig.. |

| 10 - | Joint protective boot for 90 mm Ø constant velocity joint |

| q | Check for splits and chafing. |

| q | Allow air to enter joint protective boot briefly to balance pressure before tightening small clamp in place → Fig.. |

| 11 - | Joint protective boot for 81 mm Ø constant velocity joint |

| q | Check for splits and chafing. |

| q | Allow air to enter joint protective boot briefly to balance pressure before tightening small clamp in place → Fig.. |

| 12 - | Outer constant velocity joint 90 mm Ø for vehicles with output of 55 kW and above |

| q | Renew only complete. |

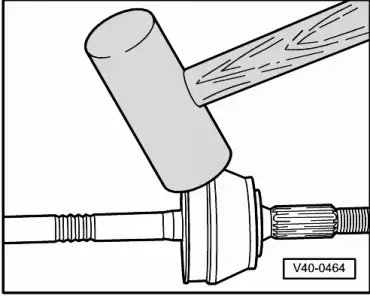

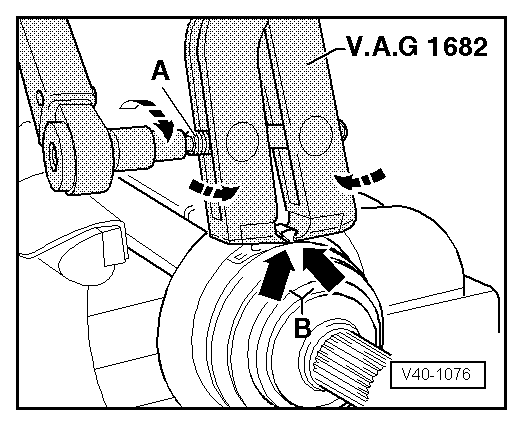

| q | Removing → Fig. |

| q | Installing: drive onto shaft with plastic hammer until compressed retaining ring seats. |

| q | Greasing → Chapter |

| q | Checking → Chapter |

| 13 - | Outer constant velocity joint 81 mm Ø for vehicles with output up to 48 kW |

| q | Renew only complete. |

| q | Removing → Fig. |

| q | Installing: drive onto shaft with plastic hammer until compressed retaining ring seats. |

| q | Greasing → Chapter |

| q | Checking → Chapter |

| 14 - | Retaining ring |

| q | Renew |

| q | Insert in groove in shaft. |

| 15 - | Thrust washer |

| 16 - | Dished spring |

| q | Outer Ø (concave side) contacts thrust washer. |

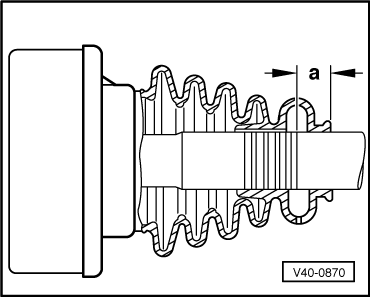

| 17 - | Drive shaft for vehicles with output of 55 kW and above |

| q | Constant velocity joint splines 4 mm longer than shafts for lower-output engines, measured from dished spring support to retaining ring groove. |

| 18 - | Drive shaft for vehicles with output up to 48 kW |

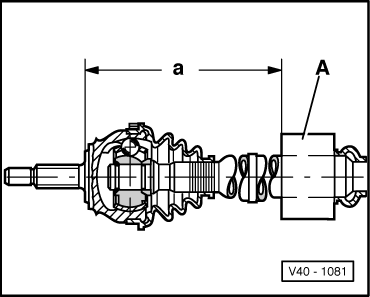

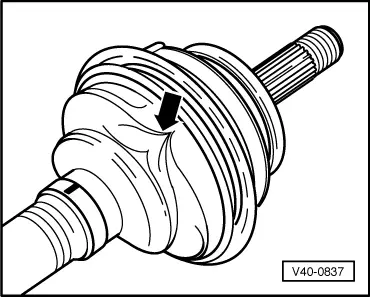

| 19 - | Damper weight |

| q | Installation position → Fig.. |

| 20 - | Constant velocity joint boot 94 and 100 mm Ø |

| q | Fitted as of 01.93. |

| 21 - | Hose clip |

| q | Tightening → Fig.. |

|

|

| Dimension “a” mm | Engine |

| 541 ± 1 | 1.8 l - 55 kW |

| 1.8 l - 66 kW | |

| 1.9 l - 48 kW | |

| 1.9 l - 55 kW | |

| 2.0 l - 85 kW | |

| 2.0 l - 110 kW | |

| 525 ± 1 | 1.9 l - 47 kW |

| 1.9 l - 66 kW |

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|