Golf Mk3

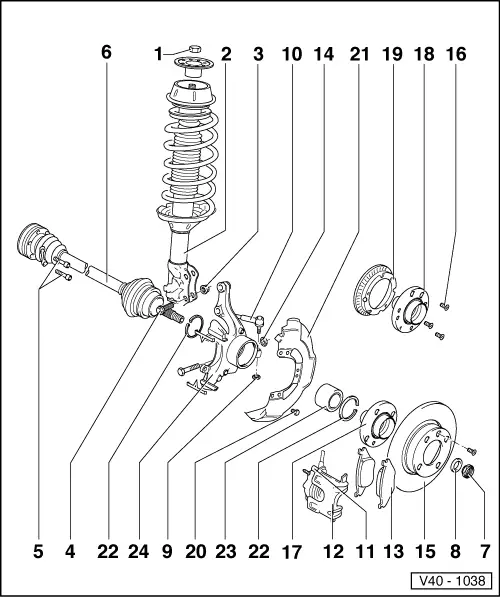

| Removing and installing wheel bearing, suspension strut, drive shaft (basic running gear) |

Note

Note| t | If a vehicle has to be moved after the drive shaft has been removed, first install an outer joint instead of the drive shaft and tighten to 50 Nm because otherwise the wheel bearing will be damaged. |

| t | It is not permitted to weld or straighten suspension parts which bear loads or locate the front wheels |

| t | Always renew self-locking nuts. |

| t | Always renew corroded nuts and bolts. |

| t | Wheel bolt tightening torque: 110 Nm |

| 1 - | Self-locking nut, 60 Nm |

| This nut is loosened when suspension strut is unbolted from body/suspension turret. |

| Each time the hexagon nut is loosened, the slotted nut on the suspension strut mounting therefore has to be re-tightened to 40 Nm! |

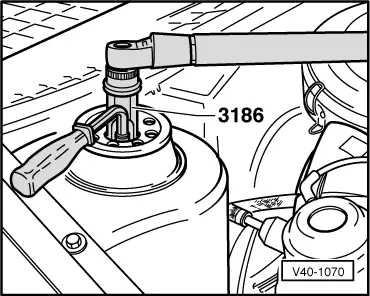

| q | Unbolting and bolting → Fig.. |

| 2 - | Coil spring strut |

| q | Dismantling and assembling → Chapter. |

| 3 - | Self-locking nut, 95 Nm |

| 4 - | Bolt |

| q | Adjusting chamber ⇒ Page → Chapter |

| q | Mark installation position before loosening |

| 5 - | 45 Nm |

| 6 - | Drive shaft |

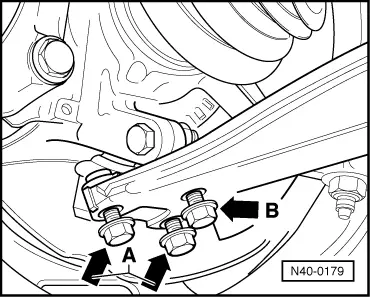

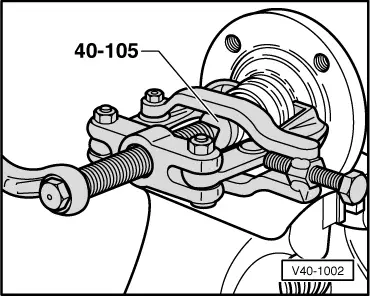

| q | To remove and install; separate suspension link and swivel joint → Fig.. |

| q | Repairing → Chapter. |

| 7 - | Self-locking nut, 265 Nm |

| q | Only loosen and tighten with the vehicle standing on its wheels (danger of accident). |

| q | Remove any paint residue or corrosion on thread of outer joint before fitting nut. |

| 8 - | Washer |

| 9 - | Self-locking nut, 35 Nm |

| 10 - | Track rod |

| q | Removing and installing → Chapter. |

| 11 - | Hexagon bolt, 25 Nm |

| 12 - | Brake caliper |

| q | Do not disconnect brake hose when working on front suspension |

| q | Tie in position with wire or similar |

| 13 - | Brake pads |

| q | Removing and installing → Chapter. |

| 14 - | 50 Nm |

| 15 - | Brake disc |

| 16 - | Cross-head screw |

| 17 - | Wheel hub |

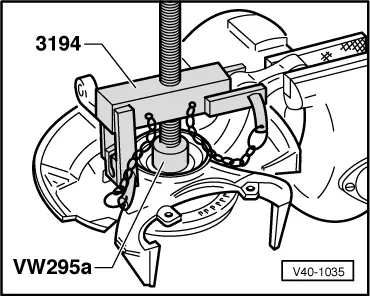

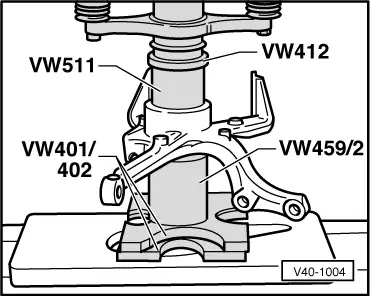

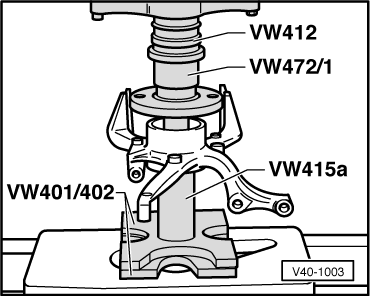

| q | Pressing out → Fig. |

| q | Pressing in → Fig.. |

| q | Pulling off inner race → Fig. |

| 18 - | Wheel hub |

| q | For vehicles with ABS. |

| q | Pressing out → Fig. |

| q | Pressing in → Fig.. |

| 19 - | Speed sensor rotor |

| q | Only on vehicles with ABS. |

| 20 - | Hexagon bolt, 10 Nm |

| 21 - | Cover plate |

| 22 - | Retaining ring |

| q | Ensure proper seating. |

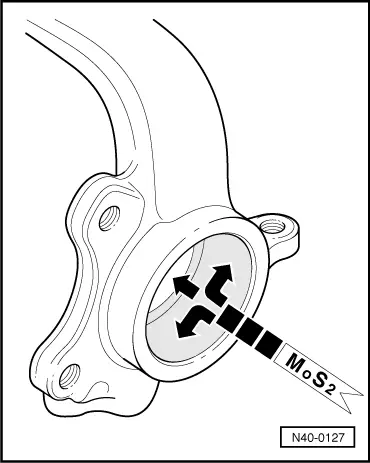

| 23 - | Wheel bearing |

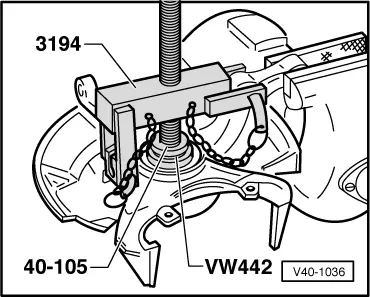

| q | Pressing out → Fig. |

| q | Renew; is destroyed when pressed out |

| q | Pressing in → Fig.. |

| 24 - | Wheel bearing housing |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|