Golf Mk3

|

Servicing drive shaft

Checking inner constant velocity joint

|

|

|

|

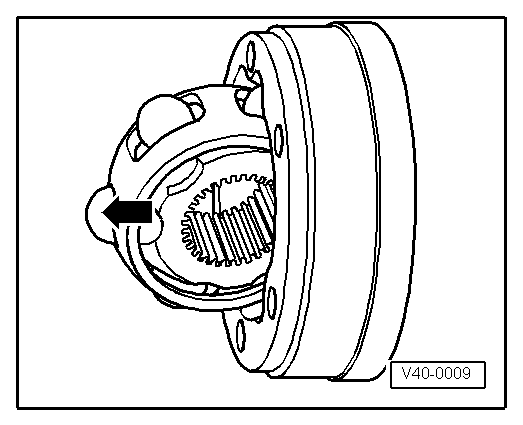

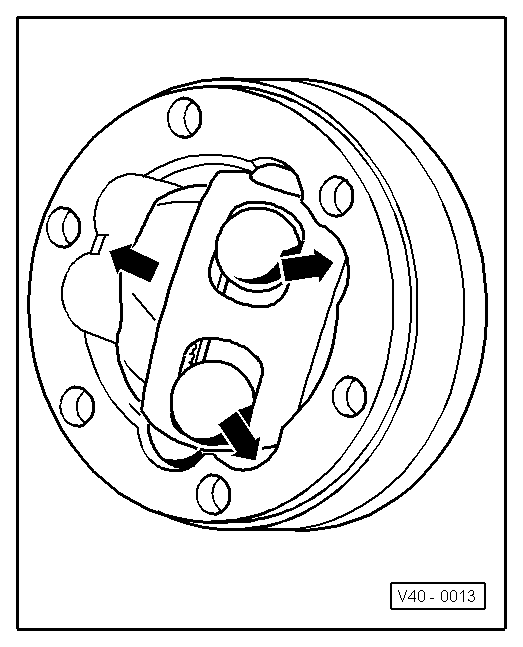

The joint should be dismantled to renew dirty grease and when checking the balls and ball tracks for wear and damage.

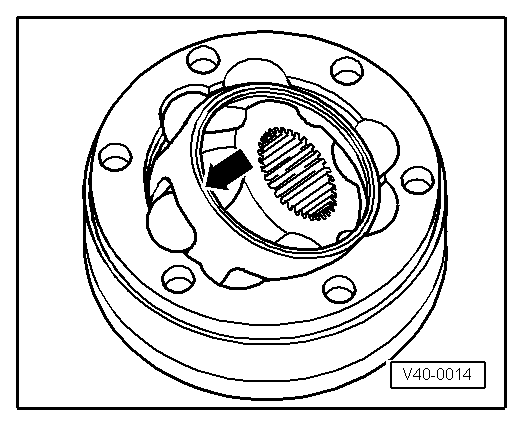

Note: The ball hub and joint are paired and must not be interchanged. |

|

|

Note: |

|

|

|

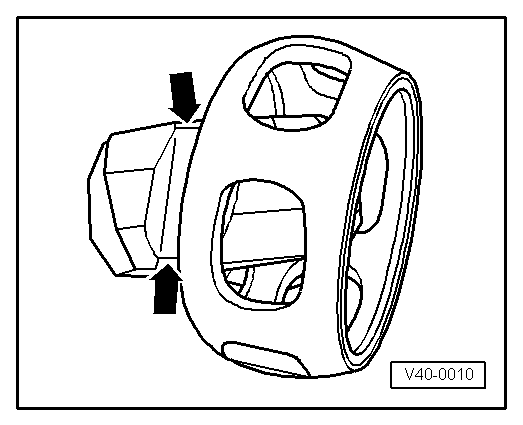

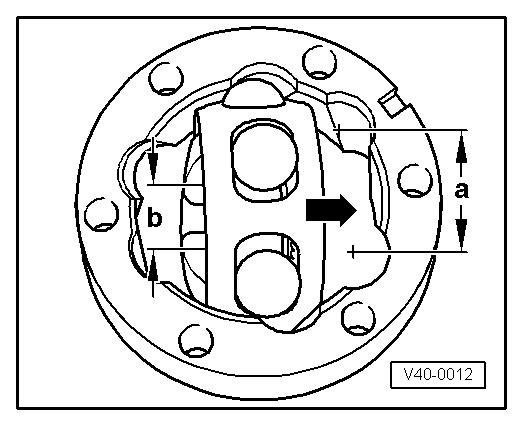

Excessive backlash in joint will be noticed as a knock during load changes. In such cases the joint must be renewed. Polished areas and ball track marks are not a reason for changing the joint. Installing:

|

|

|

|

Notes:

|

|

|

|

|

|

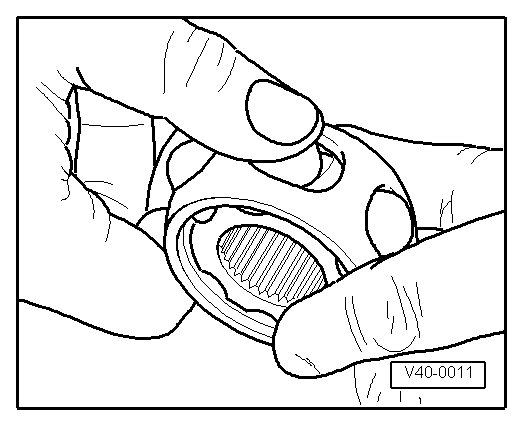

Checking operation of constant velocity joint: The constant velocity joint is correctly assembled when the ball hub can be moved by hand backwards and forwards over its entire axial movement range. |