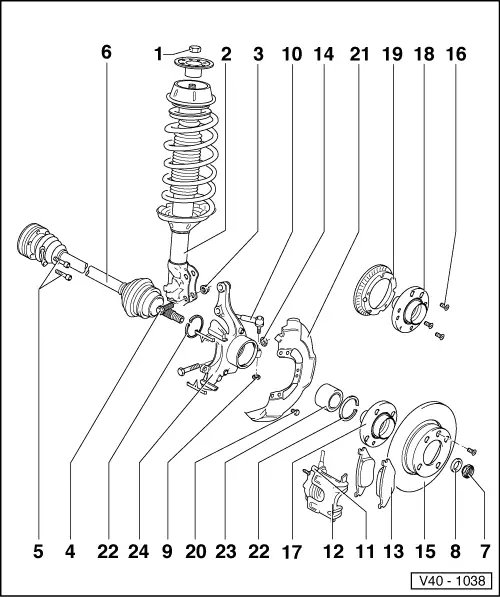

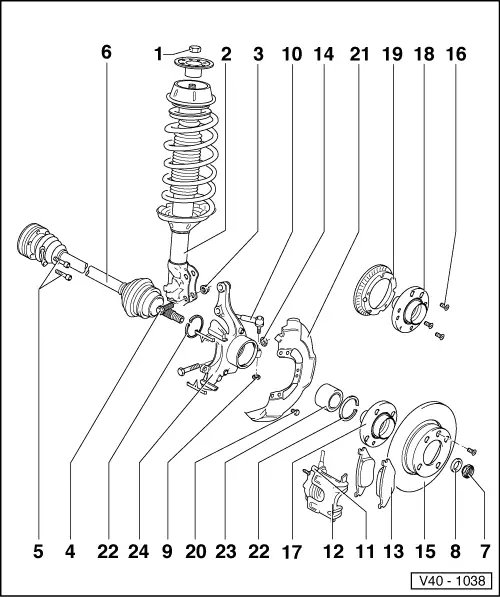

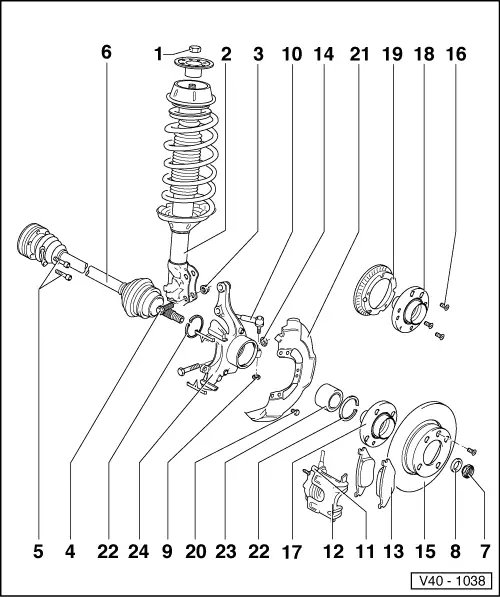

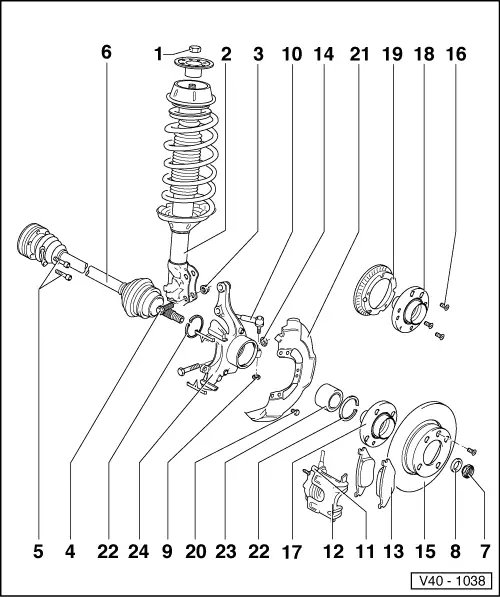

Golf Mk3

|

Servicing front suspension (Base running gear)

Removing and installing wheel bearing, suspension strut and drive shaft (Base running gear)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

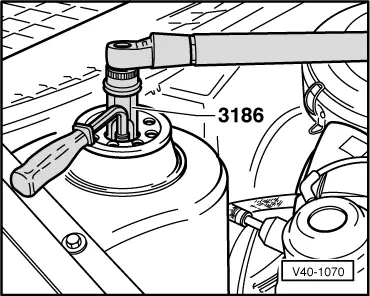

→ Fig.1 Removing and installing suspension strut to body |

|

|

|

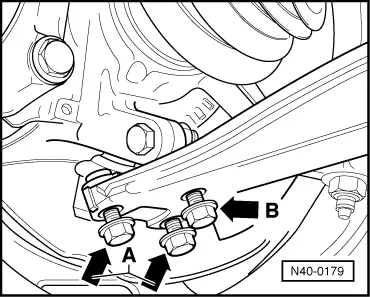

→ Fig.2 Separating ball joint/wishbone connection

Note: First mark installation position |

|

|

|

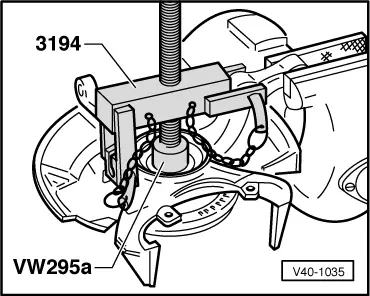

→ Fig.3 Pressing hub out of wheel bearing housing |

|

|

|

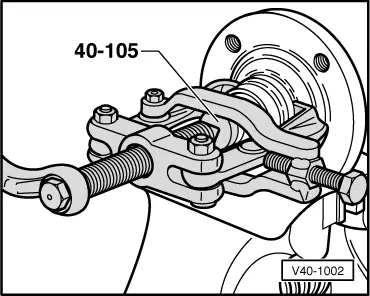

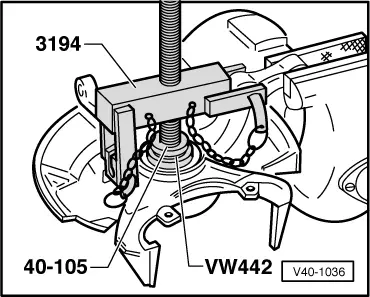

→ Fig.4 Pulling bearing race out of hub Only use puller with leg clamp e.g. Kukko 204-2 (commercial type). |

|

|

|

→ Fig.5 Pressing wheel bearing out of wheel bearing housing |

|

|

|

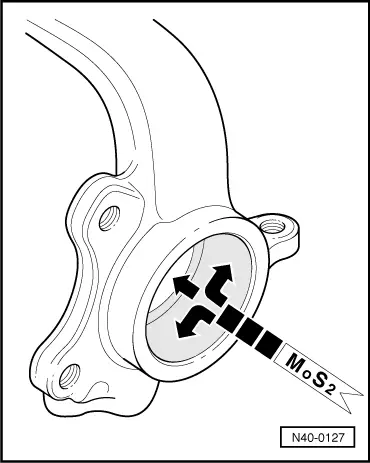

→ Coat hole completely with Molykote grease. |

|

|

|

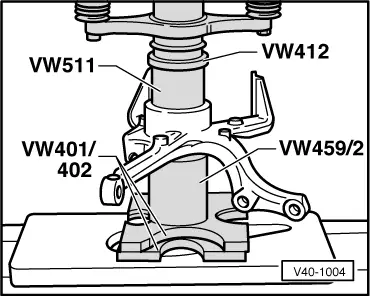

→ Fig.6 Pressing wheel bearing into wheel bearing housing |

|

|

|

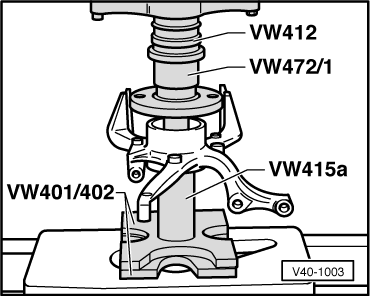

→ Fig.7 Pressing hub into wheel bearing |