| t

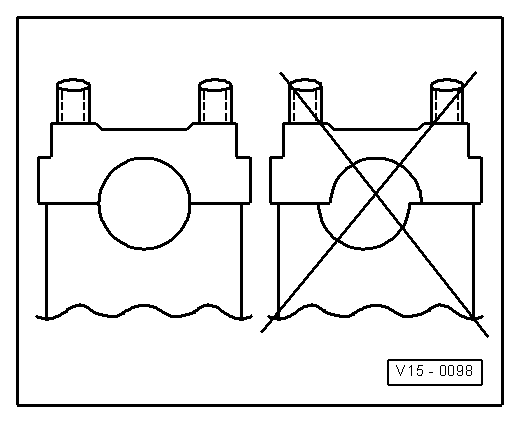

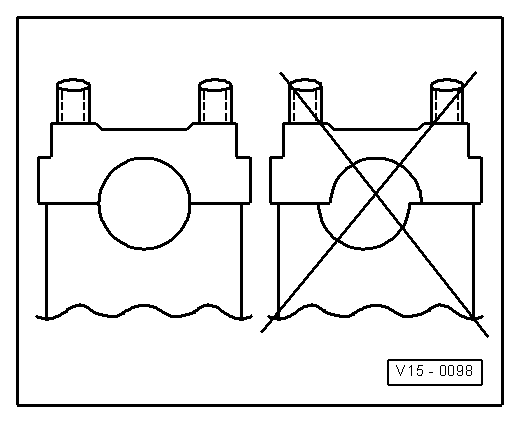

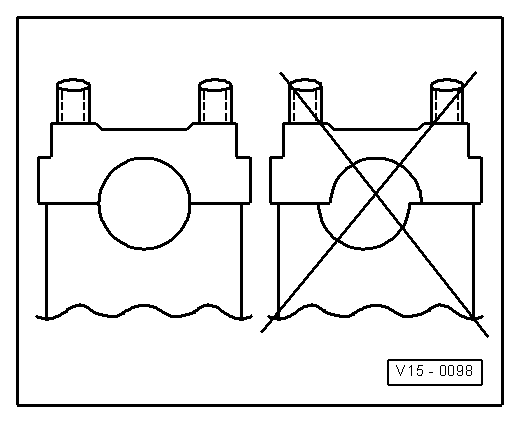

| When installing bearing caps, note that caps are not symmetrical; before installing bearing cap, set in place and determine fitting position. |

| –

| Oil camshaft running surfaces. |

| –

| Tighten bearing caps 2 and 4 alternately and diagonally to 20 Nm. |

| –

| Lightly coat contact surface of bearing cap 1 with sealant -AMV 174 004 01-. |

| –

| Install bearing caps 3, 1, and 5 and tighten to 20 Nm. |

| –

| Insert woodruff key in camshaft. |

Caution | When camshaft is turned, crankshaft must not be at TDC. Danger of damage to valves and piston crowns. |

|

| –

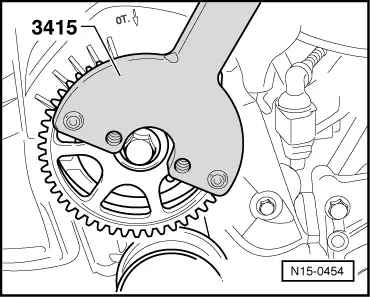

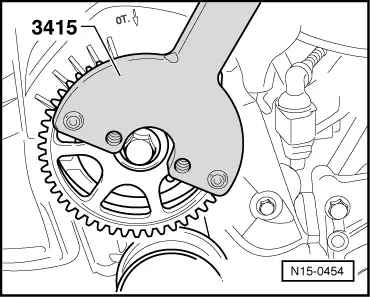

| Install camshaft belt pulley. When tightening bolt of camshaft belt pulley, secure with counterhold -3415-. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note