Golf Mk4

|

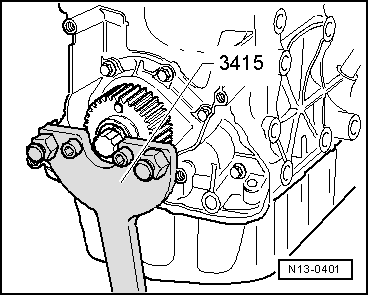

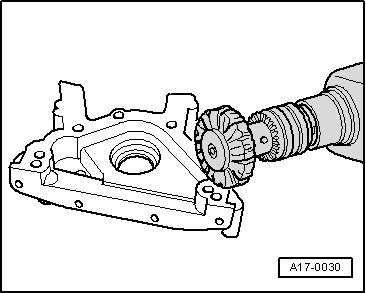

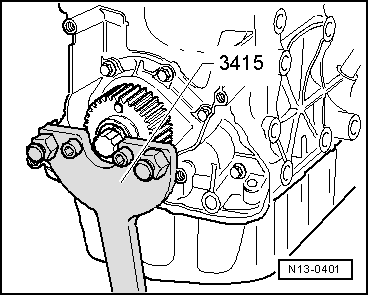

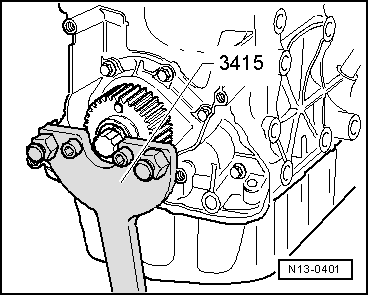

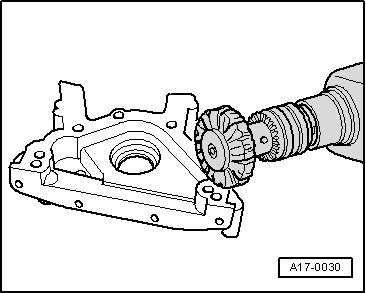

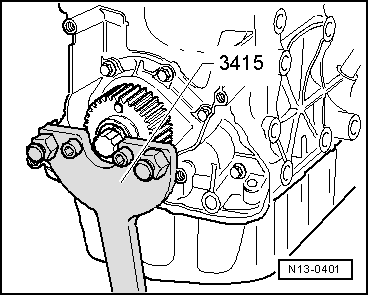

Removing and installing sealing flanges and flywheel/drive plate

Removing and installing front sealing flange

|

|

|

|

|

|

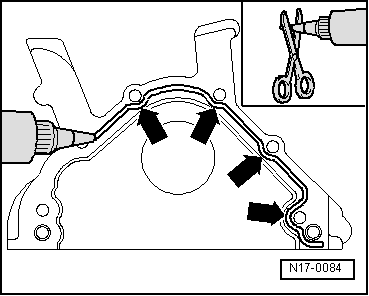

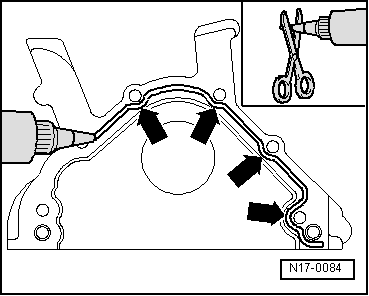

Installing |

|

|

Notes:

|

|

|

Note: Thread and shoulder must be free of oil and grease. |

|

Removing and installing sealing flanges and flywheel/drive plate

Removing and installing front sealing flange

|

|

|

|

|

|

Installing |

|

|

Notes:

|

|

|

Note: Thread and shoulder must be free of oil and grease. |