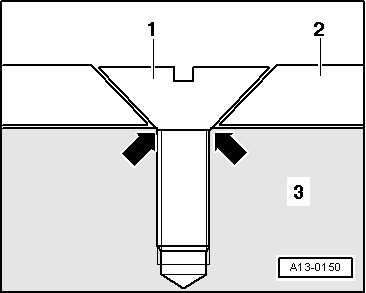

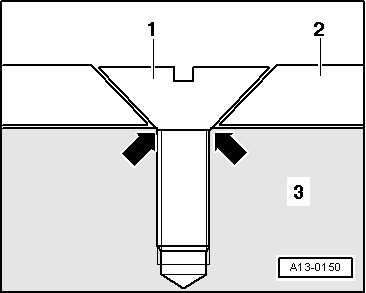

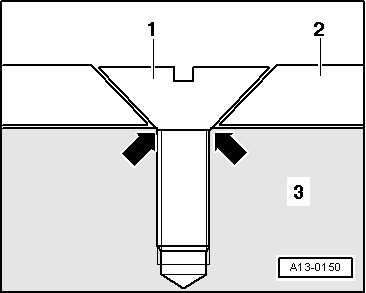

| The sender wheel must only be installed once, because after fastening for a second time, the attachment points -arrows- of countersunk head bolts -1- in sender wheel -2- are deformed to such an extent that the bolt heads make contact with the crankshaft -3- and the sender wheel below the bolts is loose. |

| –

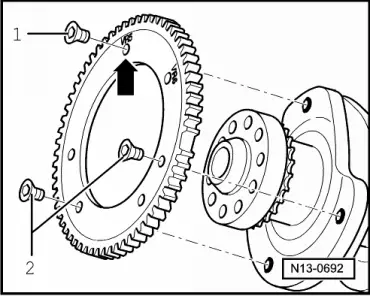

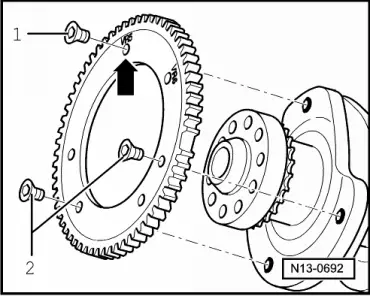

| For additional hold apply a thin coat of locking fluid „D 000 600 A2“ to crankshaft/sender wheel contact surfaces. |

| –

| Ensure during installation that -VR6- -arrow- is marked at individual threaded hole. |

| –

| First tighten all new securing bolts lightly by hand. |

|

|

|

Note

Note

Note

Note