Golf Mk6

Note

Note

|

|

|

|

|

Note

Note

|

|

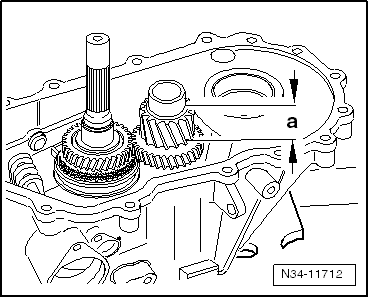

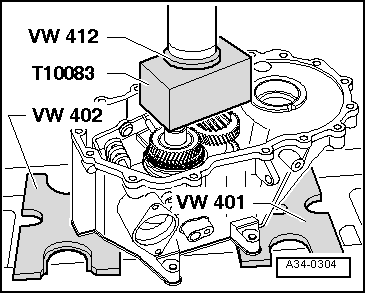

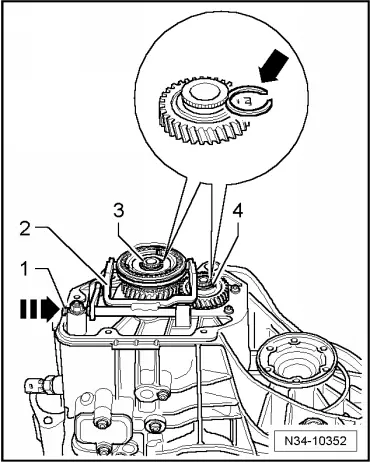

| Dimension -a- = 30.6 mm | |

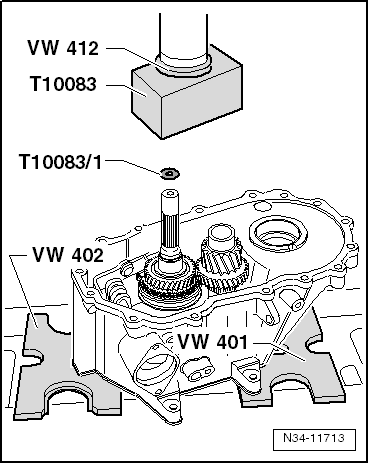

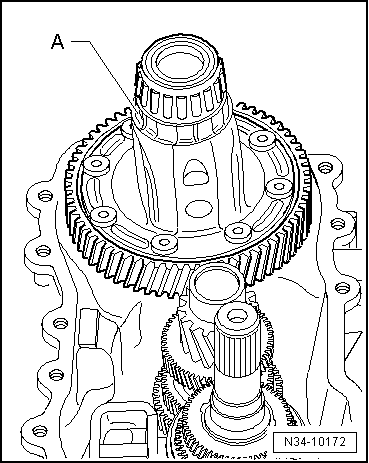

| Placing shim -T10083/1- onto input shaft → Fig. |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

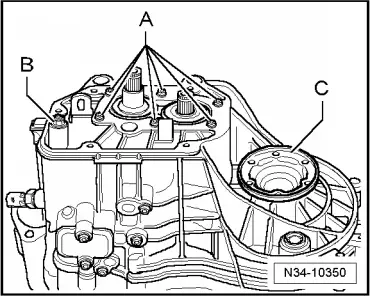

| Thickness (mm) | |

| 2.00 | 2.10 |

| 2.20 | |

|

|

|