| –

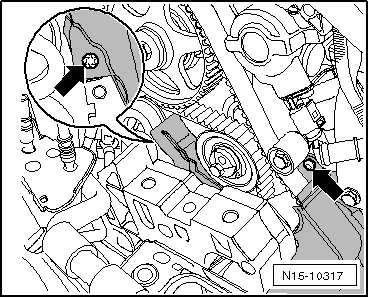

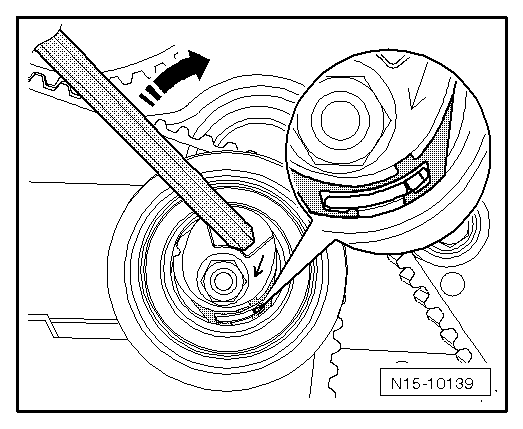

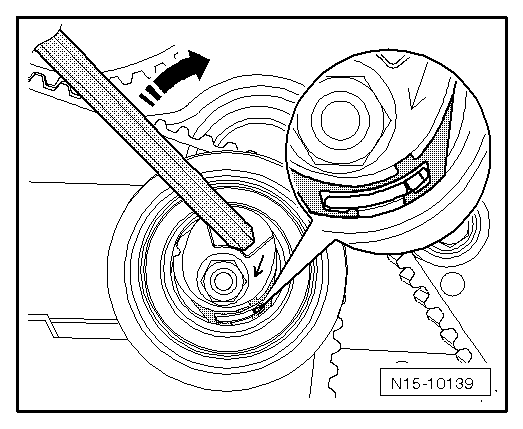

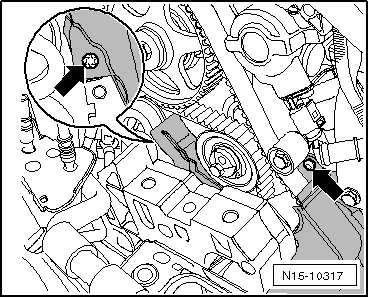

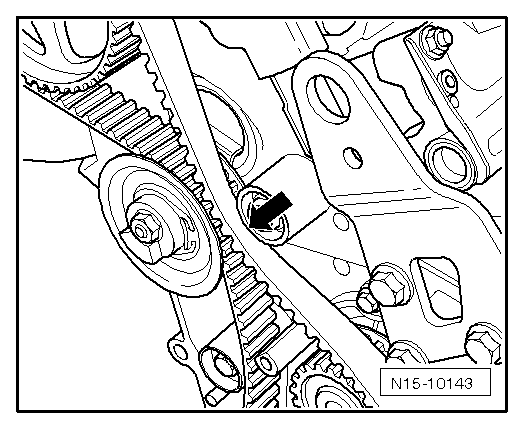

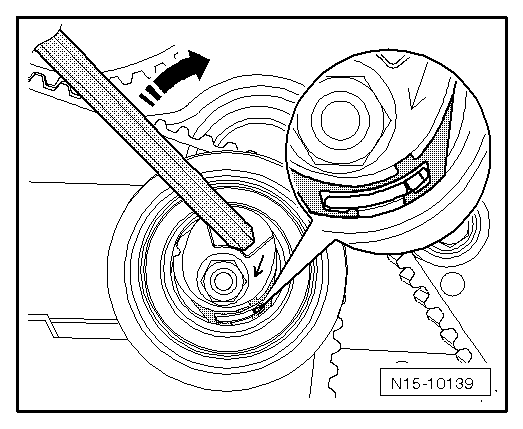

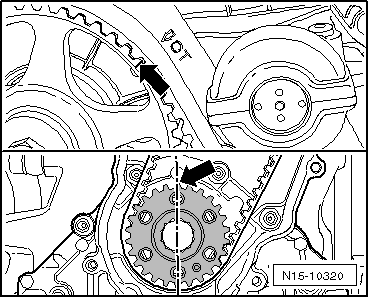

| Tension toothed belt; to do this, turn Allen key to right -direction of arrow- until notch is positioned above lug (toothed belt overtensioned). |

| –

| Relax toothed belt again. |

| –

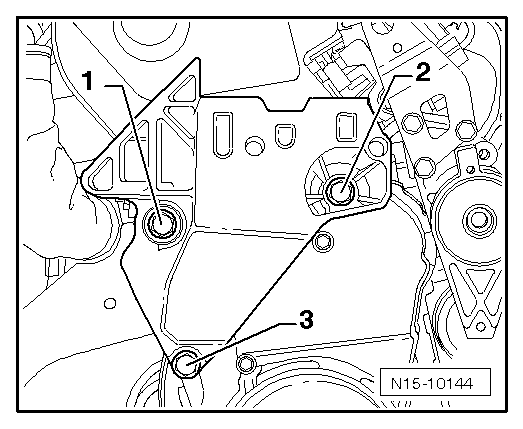

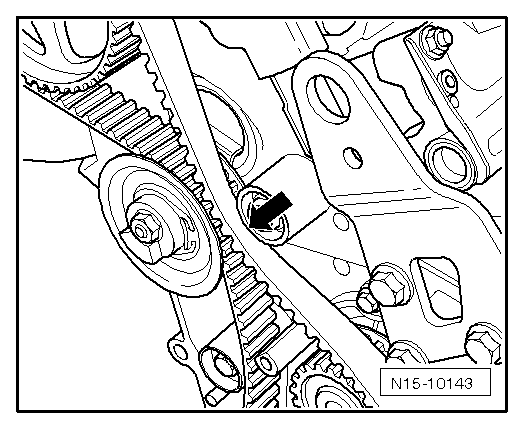

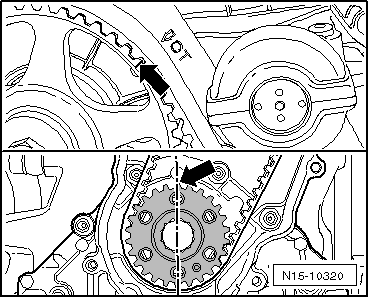

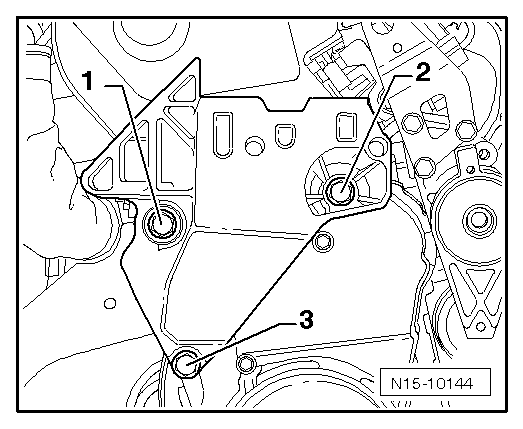

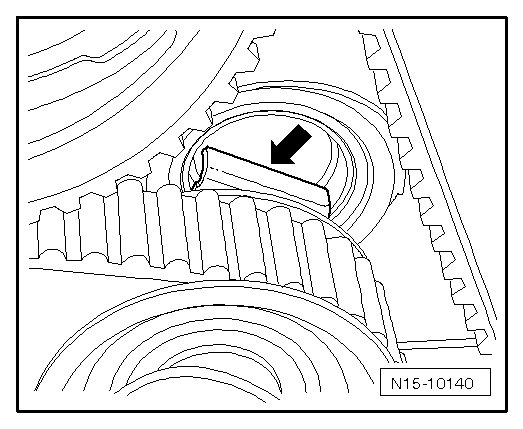

| Tension toothed belt until notch and lug are positioned opposite each other. |

| –

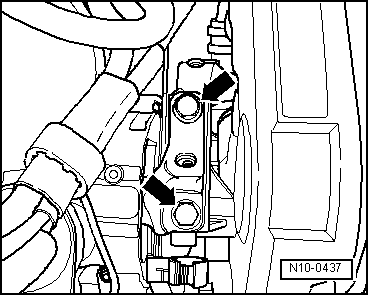

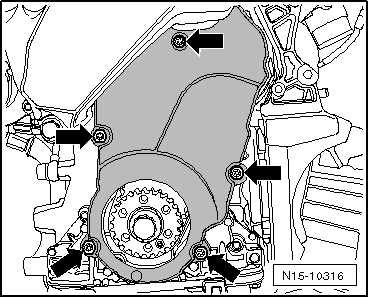

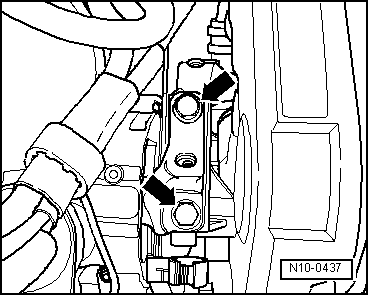

| Tighten securing nut to 25 Nm. |

| –

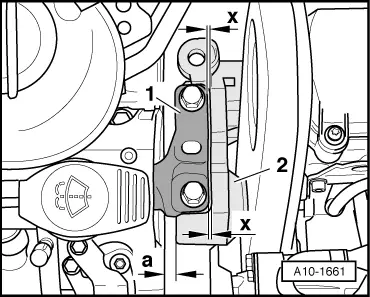

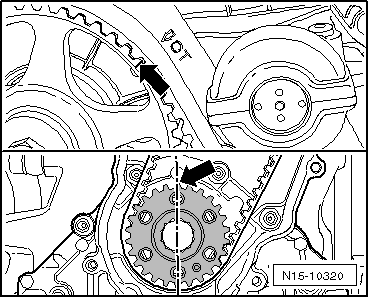

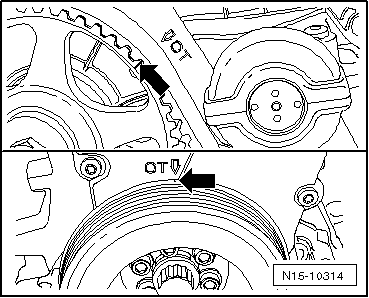

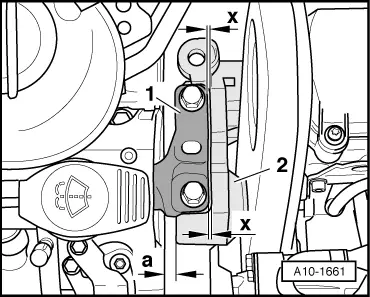

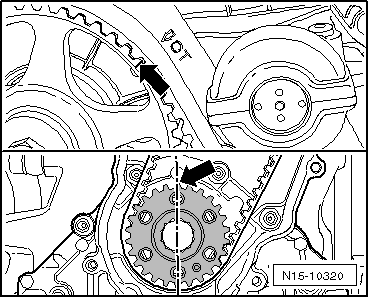

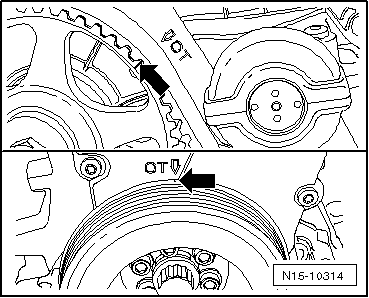

| Turn crankshaft 2 turns in engine direction of rotation until engine is again at TDC. It is important that the last 45° rotation (1/8 turn) is performed without interruption. |

| –

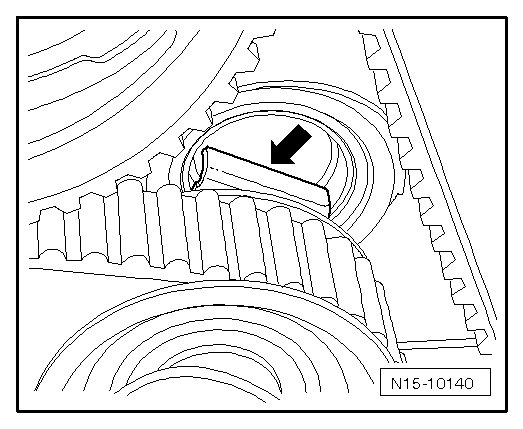

| Check toothed belt tension. Specification: indicator and notch must align. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note