| Special tools and workshop equipment required |

| t

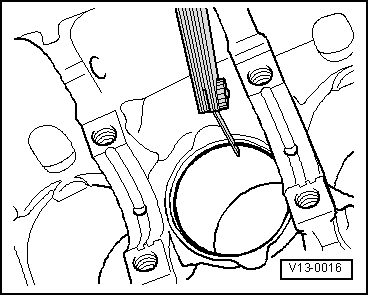

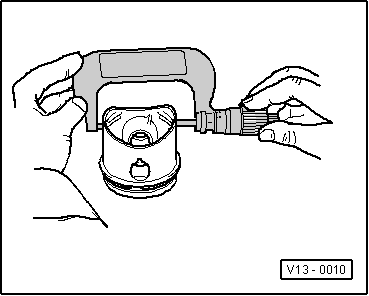

| Cylinder gauge -VAS 6078- |

| –

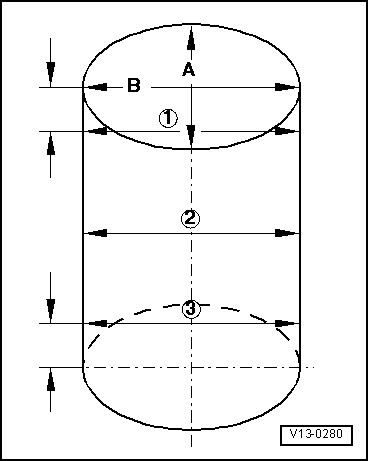

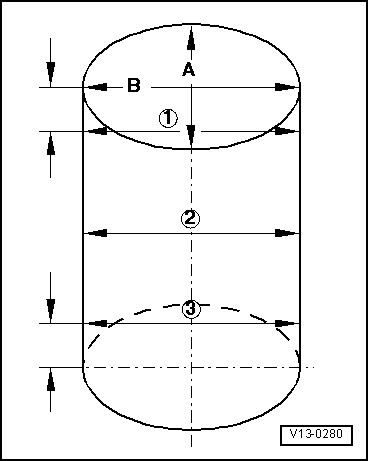

| Take measurements at 3 positions in both lateral direction -A- and longitudinal direction -B-. |

| –

| Deviation from nominal dimension max. 0.08 mm |

Note | Cylinder bores must not be measured when cylinder block is mounted on a repair stand with engine and gearbox support -VAS 6095-, as measurements may then be incorrect. |

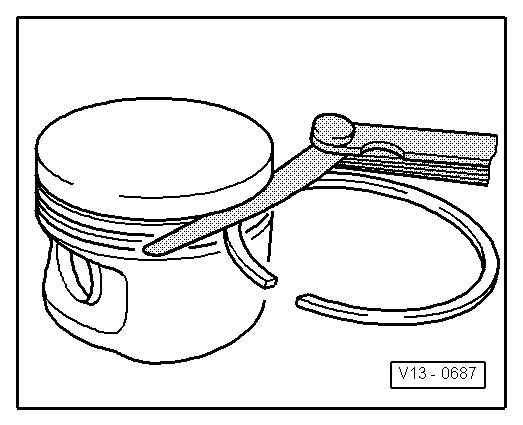

| Piston and cylinder dimensions |

Caution | The cylinder bore may not be worked on (reboring, honing, grinding) may not be carried out using workshop tools! This will damage the surface of the cylinder bore. |

|

|

|

|

Note

Note

Caution

Caution