| –

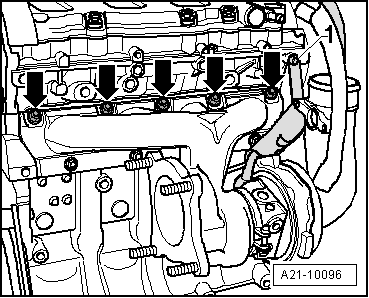

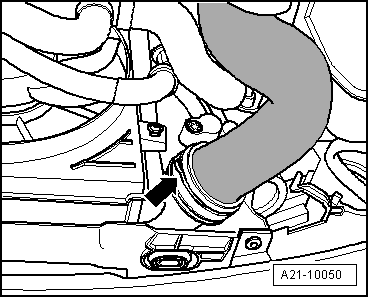

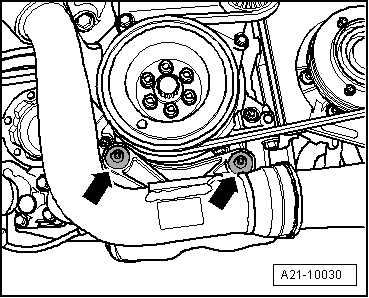

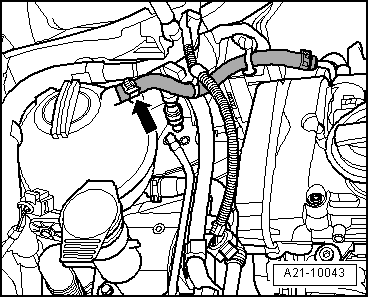

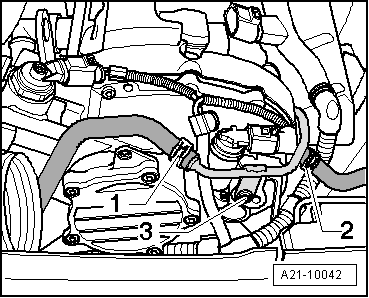

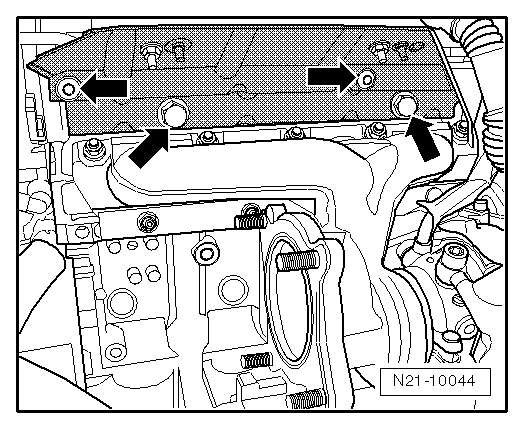

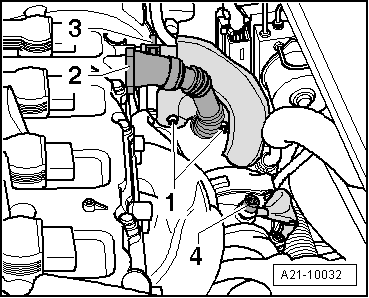

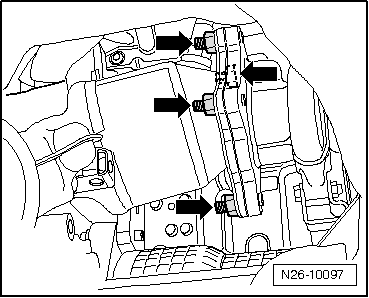

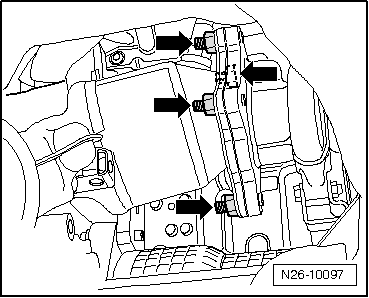

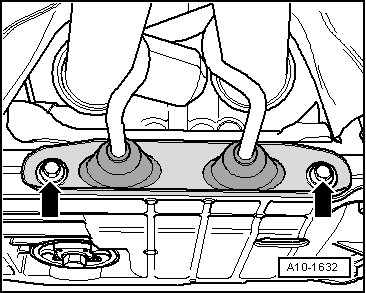

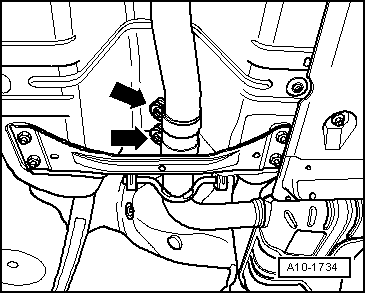

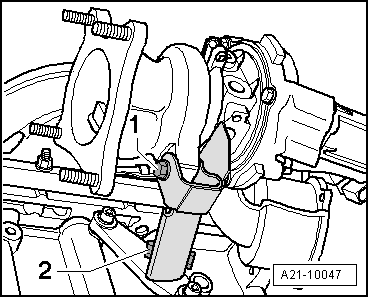

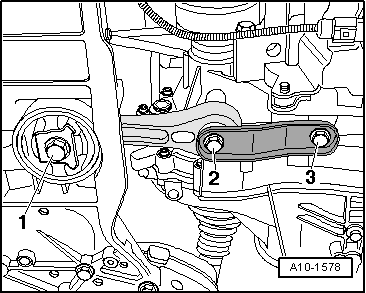

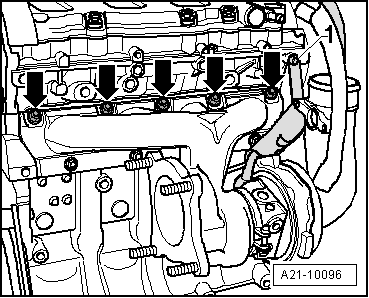

| Unscrew bolt -1- for coolant pipe and unscrew upper nuts -arrows-. |

| –

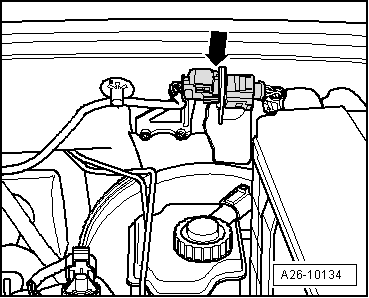

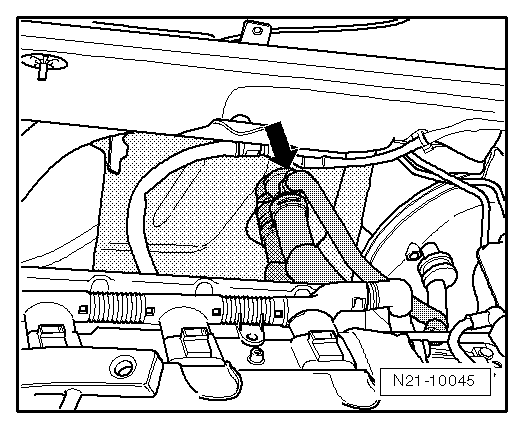

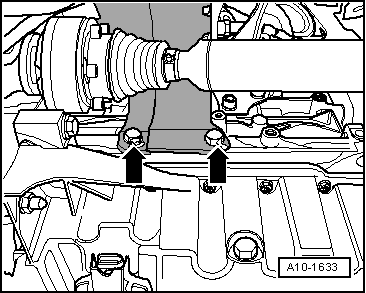

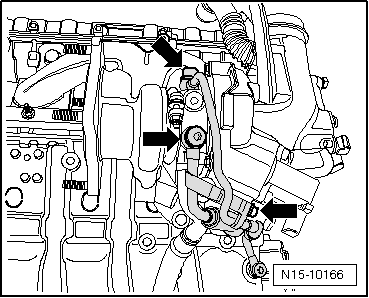

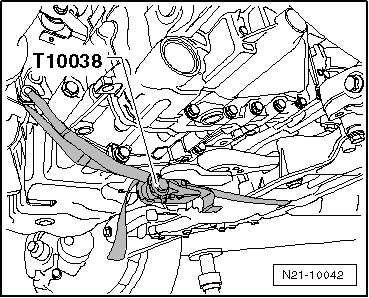

| Remove turbocharger/exhaust manifold upwards. |

Caution | When a mechanical fault is found on the turbocharger, e.g. a destroyed compressor impeller, it is not only sufficient to renew the turbocharger. To prevent this from causing further damage, perform the following repairs: |

| t

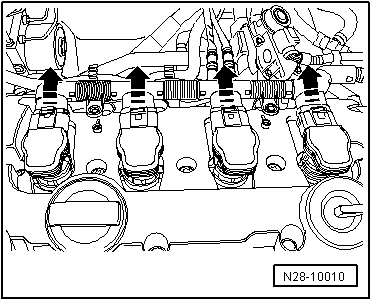

| Check air filter housing, air filter element and intake hoses for soiling. |

| t

| Check complete charged air routing and charge air cooler for foreign objects. |

| If foreign objects are found in the charge air system, the charged air routing must be cleaned and the charge air cooler must be renewed, if necessary. |

|

| Install in reverse order. In the process, note the following: |

| t

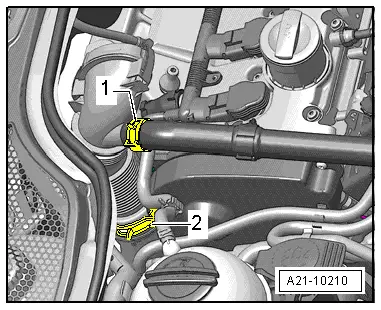

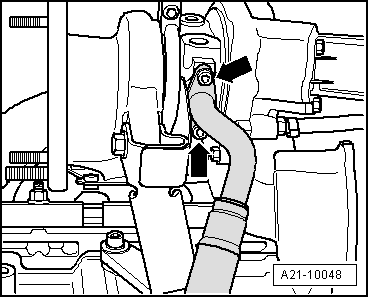

| Fitting hose connections with plug-in connectors → Chapter |

| t

| Renew gaskets, oil seals and self-locking nuts. |

| t

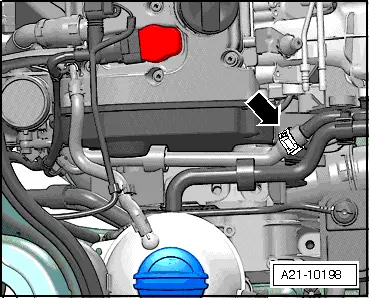

| Fill turbocharger with engine oil at connection for oil supply line. |

| t

| Install coolant return line → Item together with turbocharger. |

| t

| Hose connections and hoses for charge air system must be free of oil and grease before assembly. The oil seals and sealing surfaces must be oiled lightly only for connector couplings → Chapter. |

| t

| Secure all hose connections with hose clips comparable to production standard |

| After installing turbocharger, run engine for about 1 minute at idling speed to ensure that oil is supplied to turbocharger. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution