| –

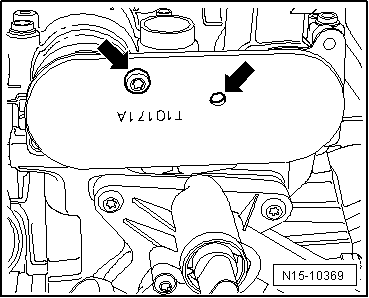

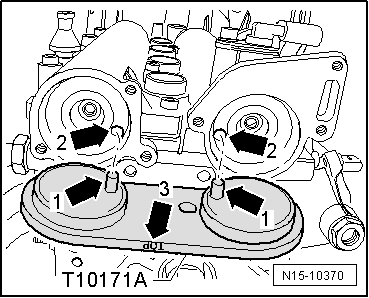

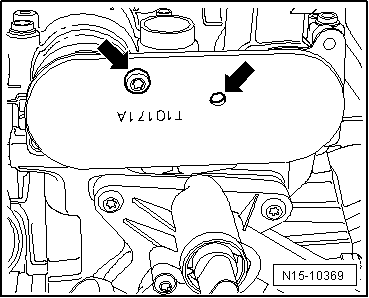

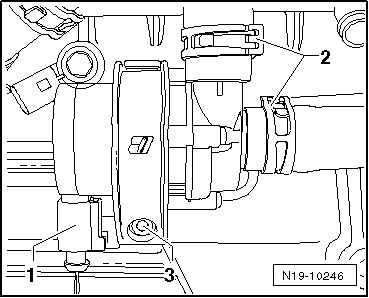

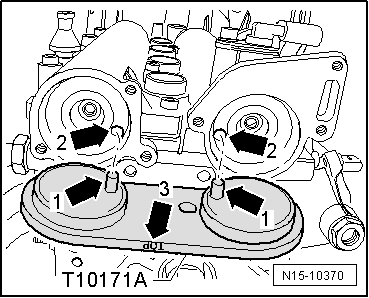

| Screw an M6 bolt hand-tight into corresponding bore -arrows- (but do not tighten) to secure camshaft clamp -T10171 A-. |

Note | Note that there are different securing points for the camshaft clamp -T10171 A-. |

| –

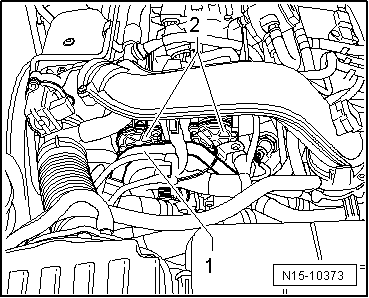

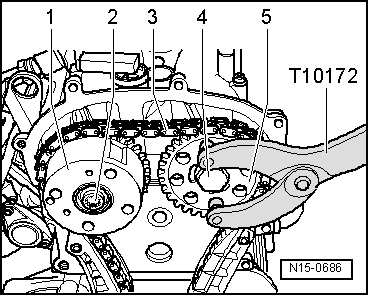

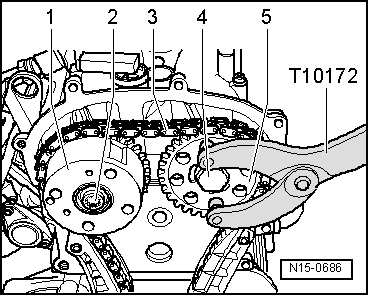

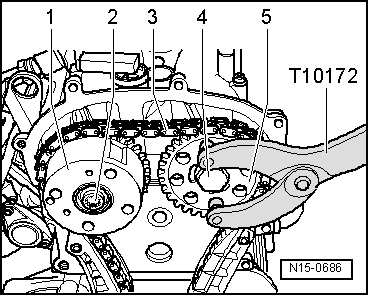

| Remove camshaft sprocket bolts. It is absolutely necessary to use counterhold -T10172- for this. |

Note | The camshaft clamp -T10171 A- must not be used as a counterhold. |

| –

| Remove one camshaft sprocket. |

| –

| Place timing chain over camshaft sprockets, observing chain direction of rotation, and install camshaft sprocket again. |

| –

| Tighten camshaft bolts until camshaft sprockets can still just be turned on camshafts. |

| –

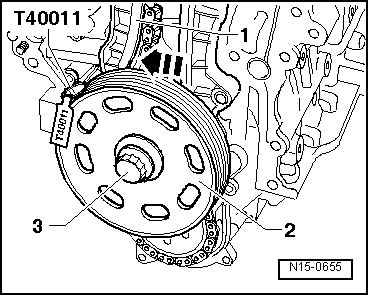

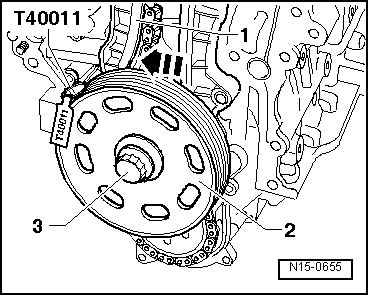

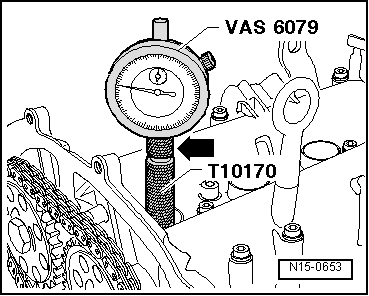

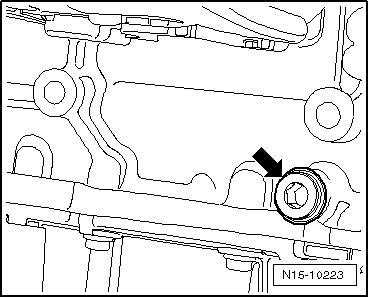

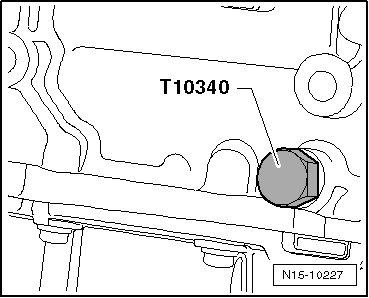

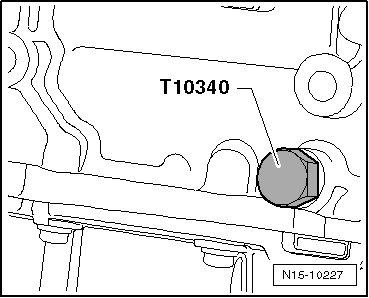

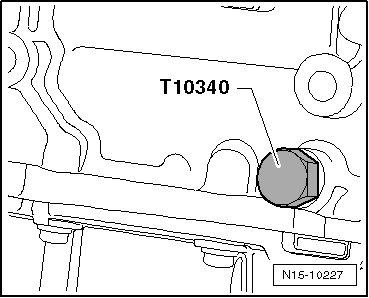

| Tension timing chain by removing locking pin -T40011-. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Caution

Caution