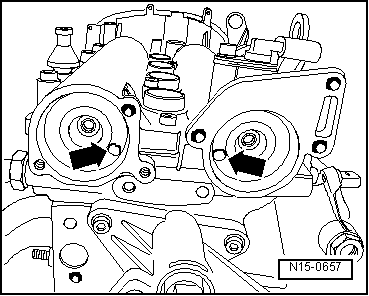

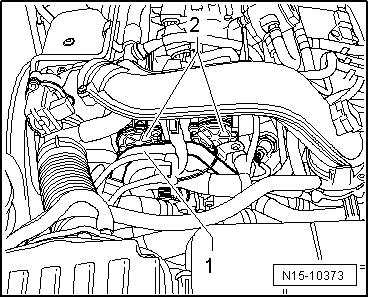

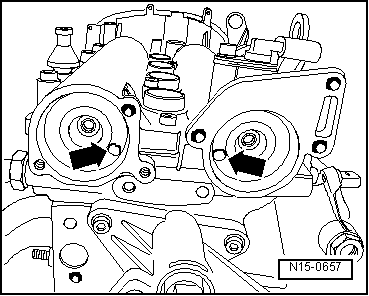

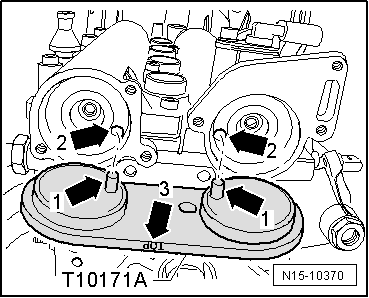

| The holes -arrows- in the camshaft must align as shown. Otherwise turn crankshaft one rotation (360°) further. |

Note | t

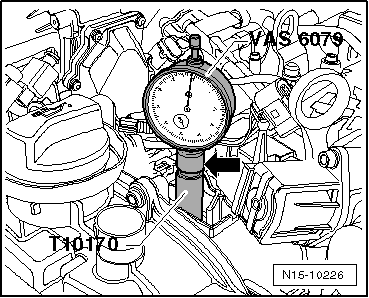

| If crankshaft is turned more than 0.01 mm past TDC, then turn crankshaft back 45° against engine direction of rotation. Then turn crankshaft in direction of engine rotation to TDC for No. 1 cylinder. |

| t

| Permissible deviation from TDC for No. 1 cylinder: ± 0.01 mm. |

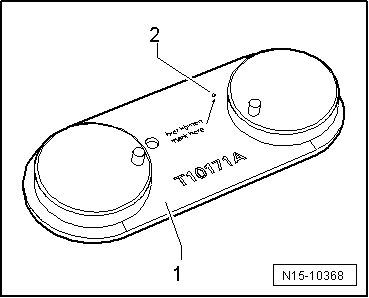

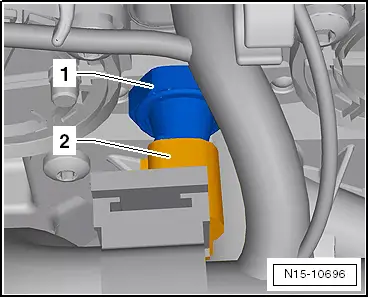

Caution | Before using camshaft clamp -T10171 A- you must check that the pins on the tool project by at least 7 mm. |

| If this is not the case, the camshaft clamp is defective and must be renewed. |

| The camshaft clamp must not be positioned using any kind of hammer. |

|

|

|

|

Note

Note

Note

Note

Caution

Caution