Passat (B3)

|

Dismantling and assembling bevel box

Dismantling and assembling sequence

|

|

|

|

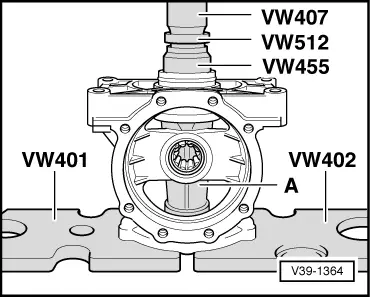

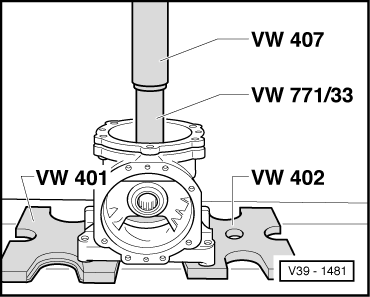

Dismantling bevel box

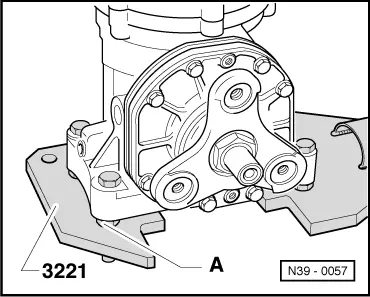

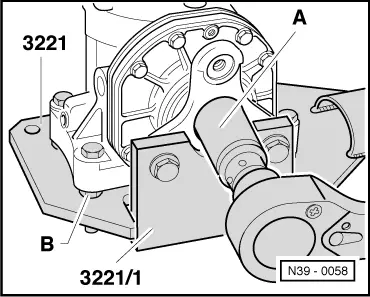

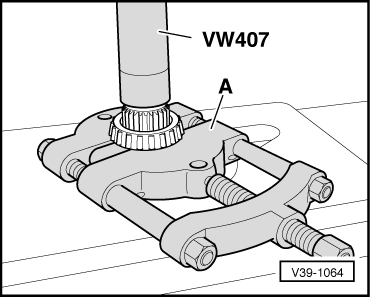

Note: If the output flange hexagon nut is not to be loosened, then the bevel box can be held in gearbox support 2004 for dismantling and assembling. |

|

|

|

|

|

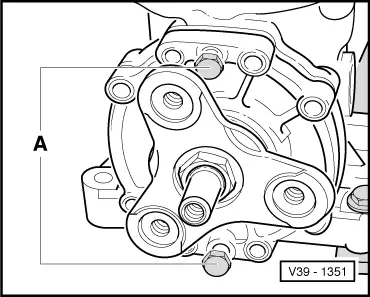

Note: Pinion housing can also be removed and installed with the output flange fitted.

|

|

|

|

B - Internal puller 46...58 mm, e.g. Kukko 21/7 |

|

|

|

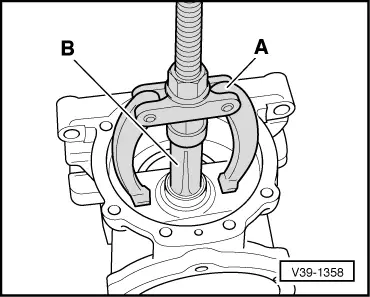

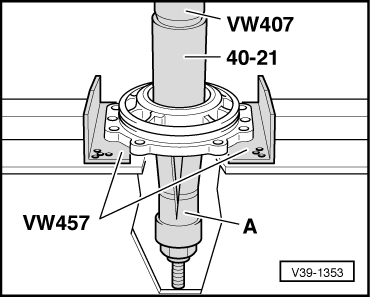

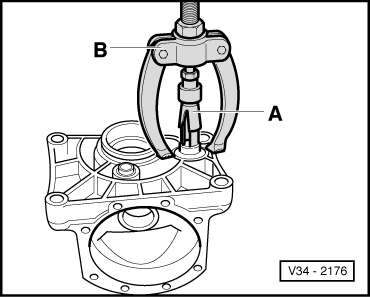

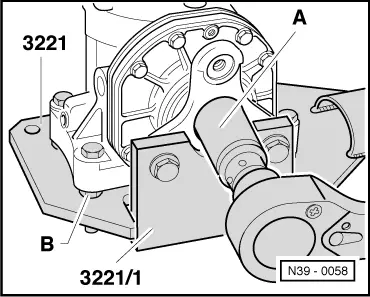

A - Internal puller 46 ... 58 mm, e.g. Kukko 21/7 B - Counter support, e.g. Kukko 22/2 |

|

|

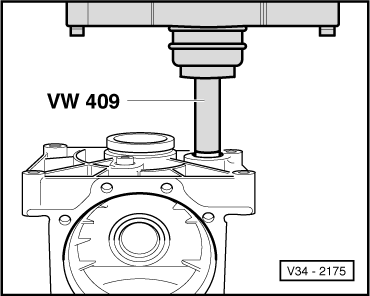

Gearbox for vehicles with 6 cylinder injection engine:

|

|

|

Note: Lever out seal first if necessary. |

|

|

|

A - Internal puller 56...70 mm, e.g. Kukko 21/8 |

|

|

|

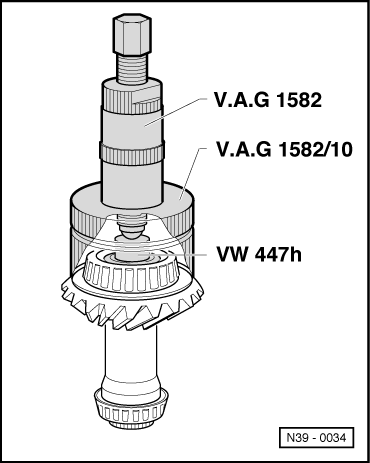

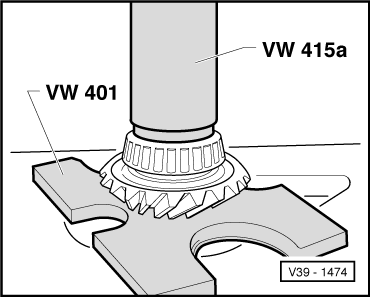

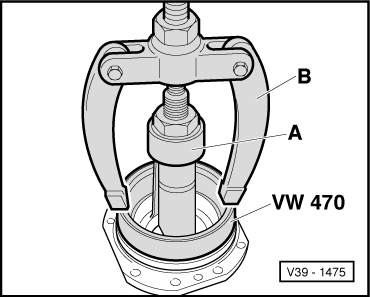

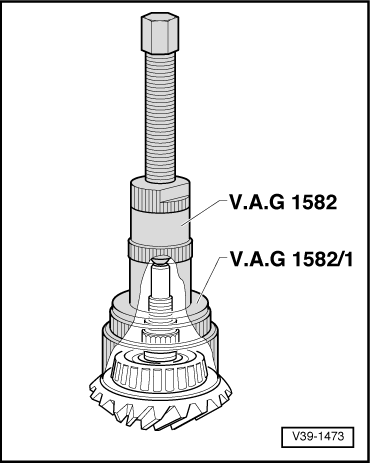

A - Separating device 22 ... 115 mm, e.g. Kukko 17/2 Note: Inner race can also be pressed off using taper roller bearing puller V.A.G 1582 and extractor V.A.G 1582/3 but first place press piece 40-105 on input shaft. |

|

|

|

A - Internal extractor 45 ... 58 mm, e.g. Kukko 21/7 |

|

|

|

A - Internal extractor 8 ... 12 mm, e.g. Kukko 21/02 B - Counter support, e.g. Kukko 22/1

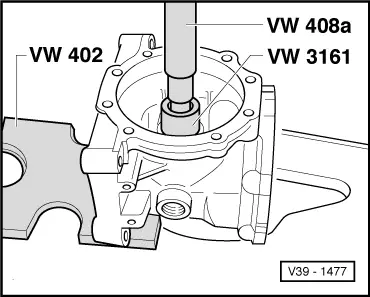

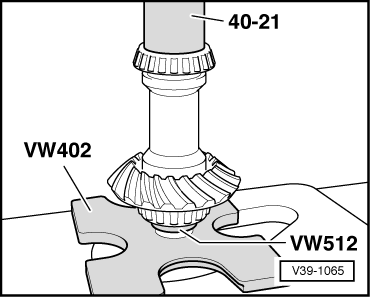

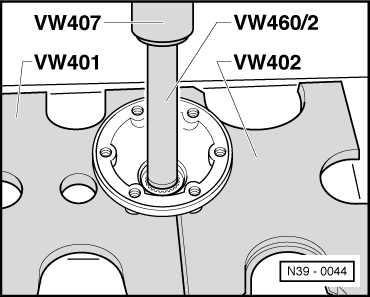

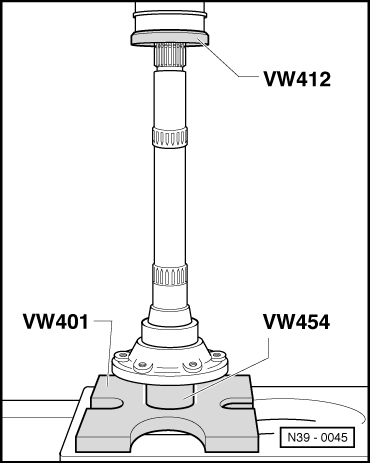

Assembling bevel box Note: See adjustment overview . |

|

|

|

|

|

|

|

|

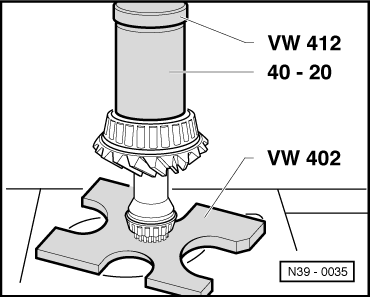

Note: Interrupt pressing operation as soon as possible to allow the press tool VW 711/33 to be seated over the complete circumference of the outer race. |

|

|

|

|

|

|

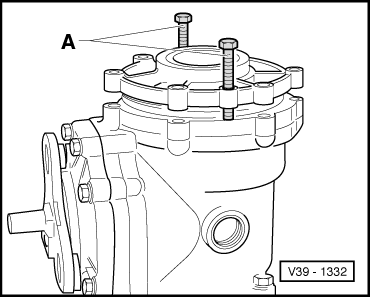

Note: Do not cant during installation, tighten securing bolts in a diagonal sequence and in stages. |

|

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

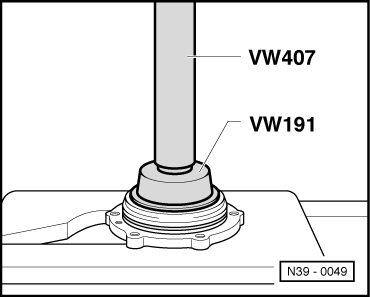

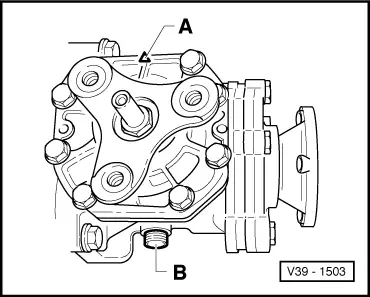

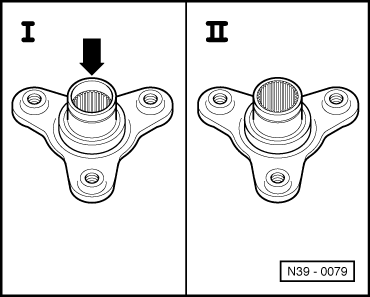

Note: → Identifying output flange: I - Gearbox for vehicles with 6-Cyl. injection engine: Splines recessed (arrow). II - Gearbox for vehicles with 4-Cyl. engine: Splines over full length. |

|

|

|

|

|

|

|

|

|