Passat (B3)

|

|

|

|

|

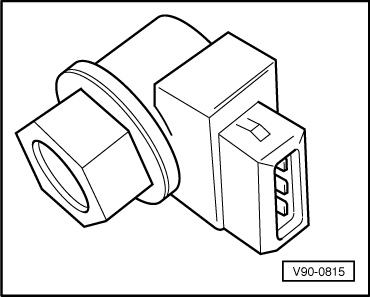

On vehicles with electronic speedometer:

|

|

|

|

|

|

|

|

|

Note: Do not depress clutch pedal. On vehicles with mechanical speedometer:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

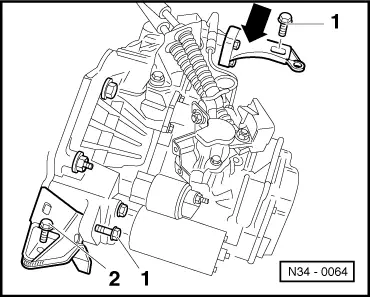

=> Repair group 27; Removing and installing starter.

|

|

|

=> Repair group 26; Removing and installing parts of exhaust system, four wheel drive.

|

|

|

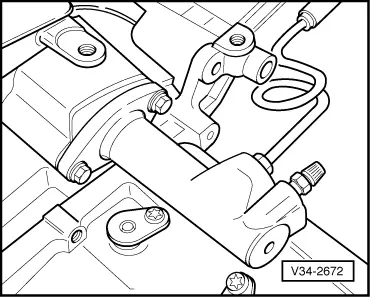

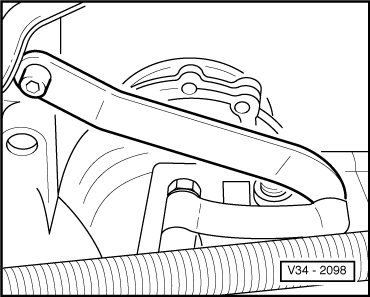

Note: When removing and installing the gearbox do not damage the seal in the propshaft flange.

|

|

|

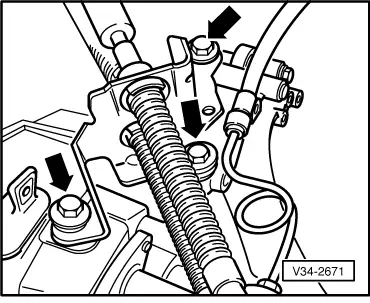

Note: Do not damage P.A.S. pipe when moving engine/gearbox assembly. |

|

|

|

|

|

|

|

|

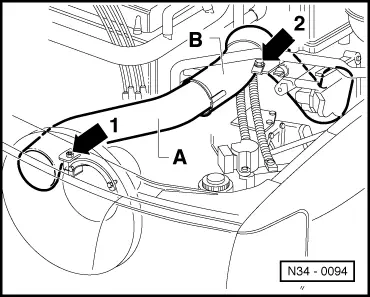

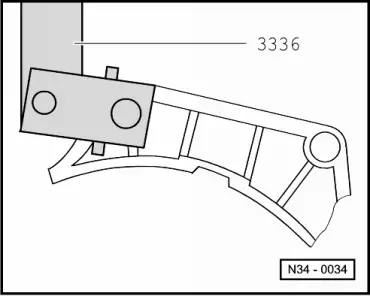

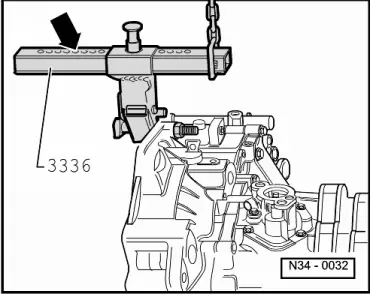

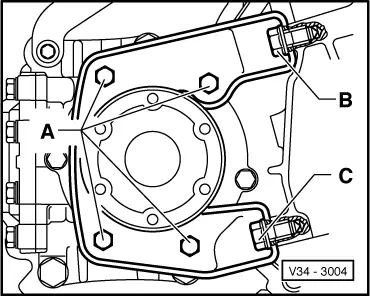

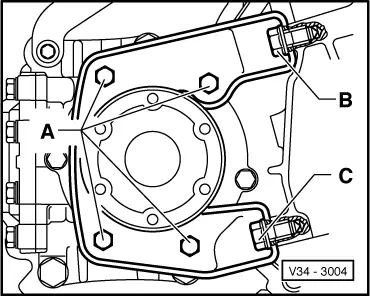

Removal position: |

|

|

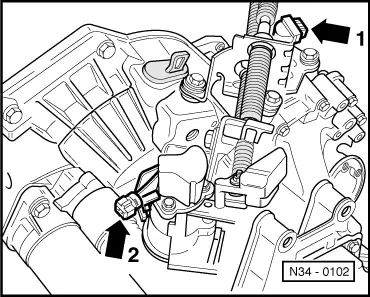

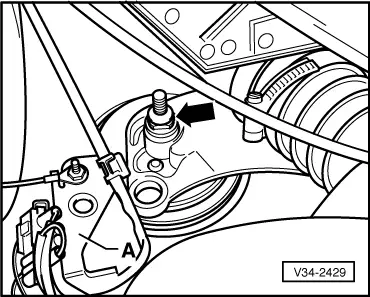

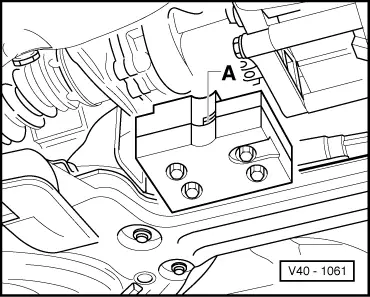

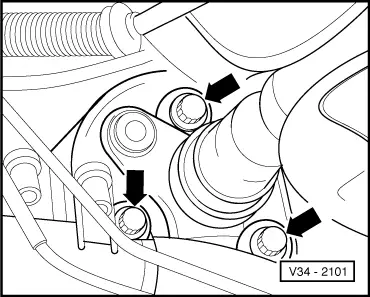

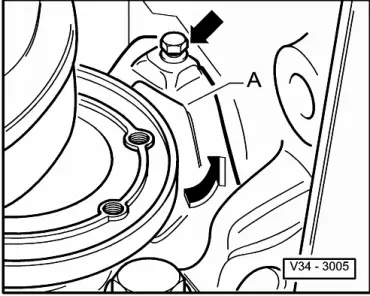

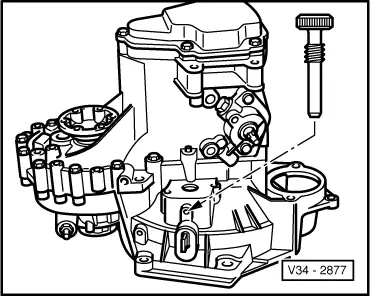

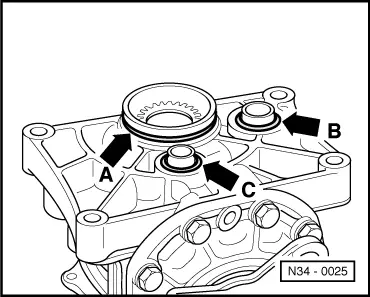

Note: → When removing and installing the bevel box do not damage the seal (arrow) in the propshaft flange.

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

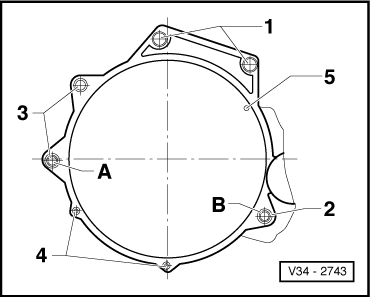

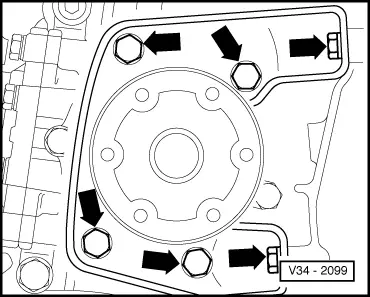

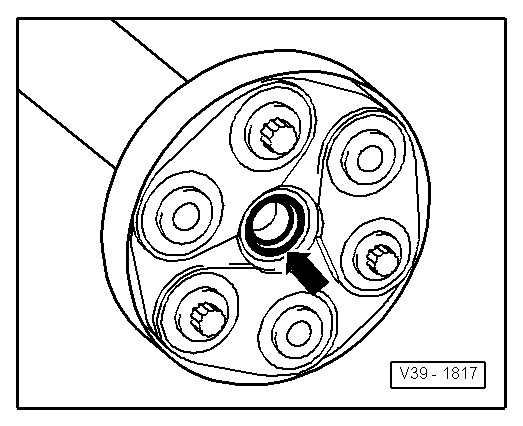

No. of holes visible = 5 |

|

|

|

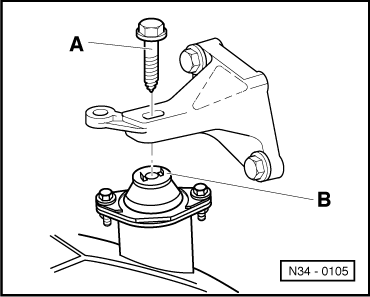

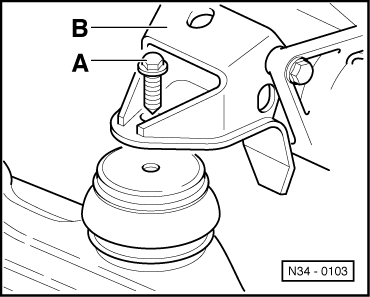

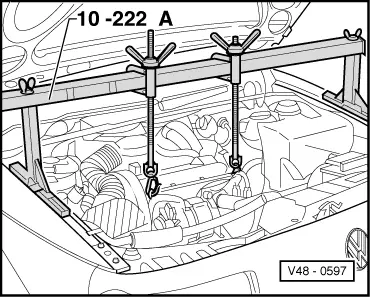

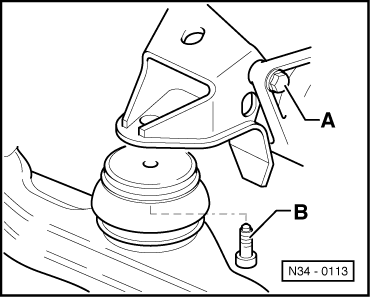

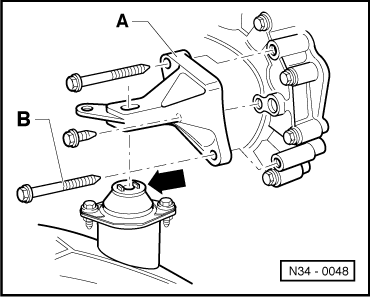

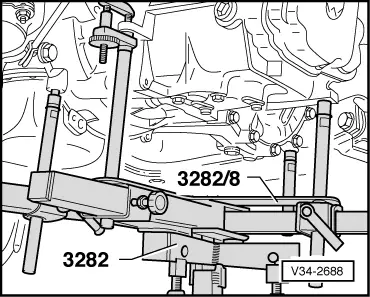

Installing Installing gearbox is carried out in the reverse sequence. When installing gearbox ensure engine/gearbox mountings are installed stress-free. => Repair group 10; removing and installing engine. Notes:

|

|

|

|

|

|

|

|

|

=> Running gear; Repair group 40; Servicing drive shaft

=> Repair group 26; Removing and installing parts of exhaust system, four wheel drive

=> Repair group 27; Removing and installing starter.

|

|

||||||||||||||||||||||

|

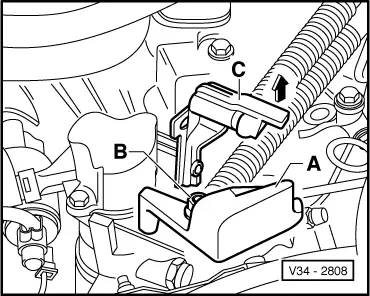

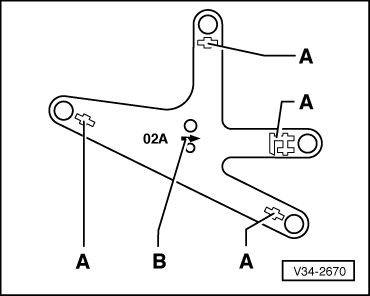

→ Assembly mountings

| ||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||