Passat (B3)

|

Repair instructions

Repair instructions

The maximum possible care and cleanliness and proper tools are essential to ensure satisfactory and successful gearbox repairs. The usual basic safety precautions also, naturally apply when carrying out vehicle repairs. A number of generally applicable instructions for individual repair operations, which are otherwise mentioned at various points in the Workshop Manual, are summarized here. They apply to this Workshop Manual. |

|

|

|

Special tool A list of the special tools used in the workshop manual precedes each repair procedure and can be found in the "Special tools/Workshop equipment" binder. The catalogue is also available as a CD-ROM, which can be ordered as normal from Bertelsmann. Gearbox When an automatic gearbox is exchanged, the VW ATF in the planetary gearbox page => 00-11 .

=> Binder: Special information; Transmission; No.10

|

|

|

Gaskets, oil seals

Locking elements

|

|

|

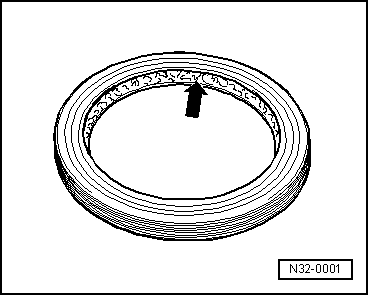

Shims

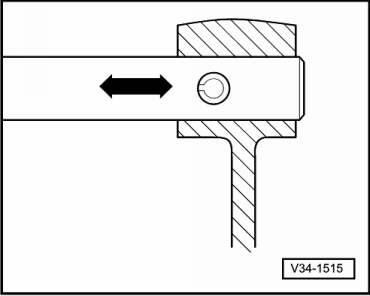

Bearings

|

|

|

|

Nuts, bolts

|

|

|

|

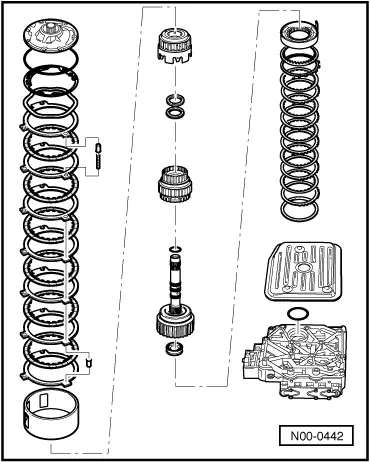

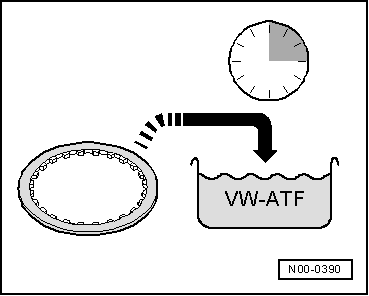

Inner plates

Valve chest

Clutches

Self-diagnosis |

|

|

|