| –

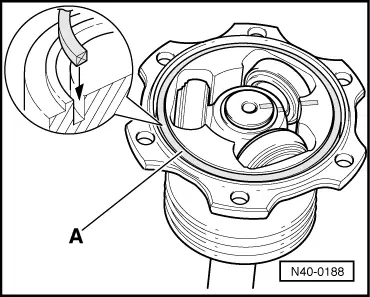

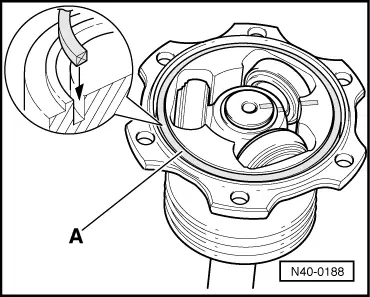

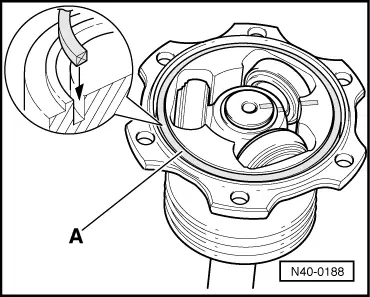

| Insert rectangular section seal -arrow- from repair set into groove. |

| The rectangular profile of the seal seals the triple roller joint and joint flange directly. |

| Therefore a cover is no longer required! |

| –

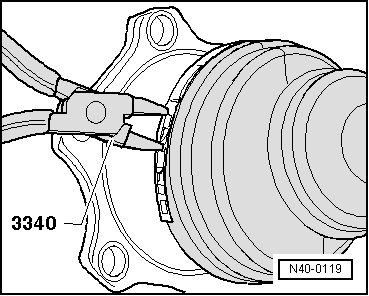

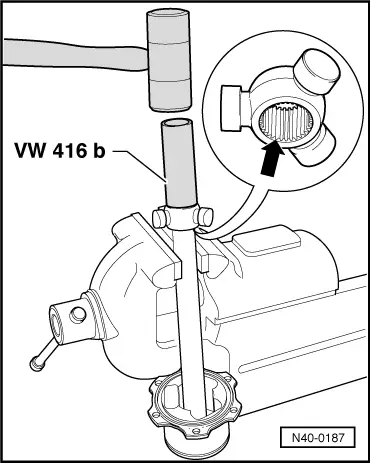

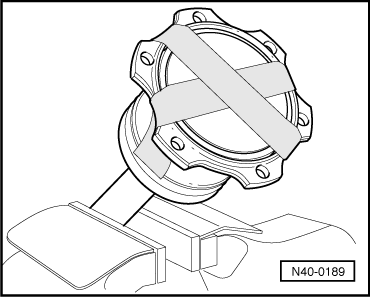

| Press 90 grammes of drive shaft grease from repair set into triple roller joint. |

| –

| Press 90 grammes of joint grease, from repair set, into the reverse side of the triple roller joint. |

|

|

|