Passat (B3)

| Repairing rear drive shaft |

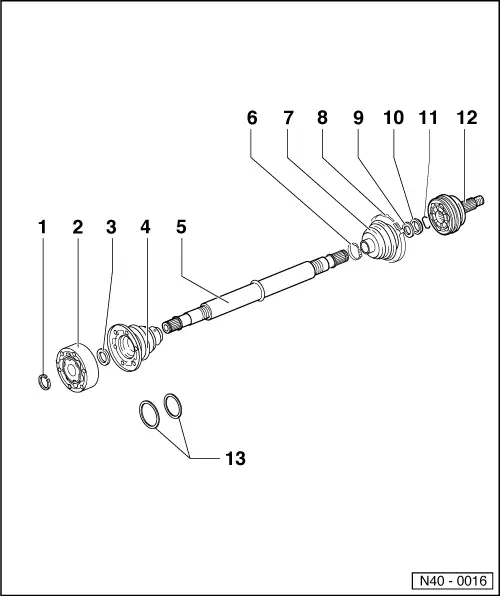

| Removing and installing drive shaft → Fig. |

Note

Note| t | Greasing: outer constant velocity joint 80 g G-6.3, inner constant velocity joint 80 g G-6.3 |

| t | Greasing outer joint: press half of the grease into the joint and the other half evenly into the bellows. |

| t | Greasing inner joint: press half of the grease into the inner joint from both sides, the other half evenly into the boot. |

| t | Regrease joint if required when renewing boot. |

| 1 - | Circlip |

| q | Renew. |

| q | Remove and install with circlip pliers -VW 161 A-. |

| 2 - | Inner constant velocity joint, 81 mm Ø |

| q | Renew only complete. |

| q | Pressing off → Fig.. |

| q | Pressing on → Fig.. |

| q | Greasing → Chapter. |

| q | Checking → Chapter. |

| 3 - | Dished spring |

| q | Splined on internal Ø. |

| q | Installation position: larger Ø (concave side) contacts constant velocity joint. |

| 4 - | Joint protective boot for 94 mm Ø constant velocity joint |

| q | Rubber version. |

| q | Check for splits and chafing. |

| q | Installation position: 1 to 11/2 indentations visible at end of boot. |

| q | Coat cap with D3. |

| q | Drive off with drift. |

| 5 - | Drive shaft |

| q | Shafts have unequal lengths - right is shorter shaft. |

| 6 - | Hose clip |

| q | Renew. |

| q | Tightening → Fig.. |

| 7 - | Joint protective boot for 81 mm Ø constant velocity joint |

| q | Polyester elastomer version. |

| q | Check for splits and chafing. |

| q | Installation position: 1 to 11/2 indentations visible at end of boot. |

| q | Allow air to enter joint protective boot briefly to balance pressure before tightening small clamp in place → Fig.. |

| 8 - | Hose clip |

| q | Renew. |

| q | Tightening → Fig.. |

| 9 - | Dished spring |

| q | Outer Ø (concave side) contacts thrust washer. |

| 10 - | Thrust washer |

| 11 - | Circlip |

| q | Renew. |

| q | Insert in groove in shaft. |

| 12 - | 81 mm Ø outer constant velocity joint |

| q | Renew only complete. |

| q | Removing → Fig.. |

| q | Installing: drive onto shaft with plastic hammer until compressed retaining ring seats. |

| q | Greasing → Chapter. |

| q | Checking → Chapter. |

| 13 - | Inner support ring |

| q | Prevents inflation of joint protective boot. |

| q | Installed only on gearbox side of left drive shaft. |