Polo Mk3

|

|

|

have been changed. Adjustment overview |

|

||||||||

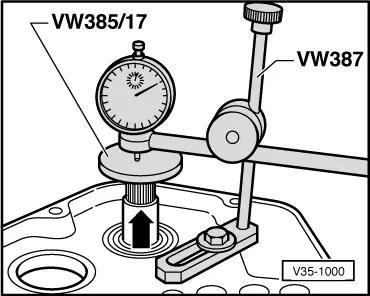

Note: This preparation is to be repeated for each subsequent measurement, otherwise the gauge will not return to the starting position.

Determining thickness of shim The specified bearing preload is obtained by adding to the reading obtained Example:

|

|

|||||||||||||||

The following adjustment shims are available:

If the size of shim required is larger than that listed in the table, insert two shims totalling the correct figure.

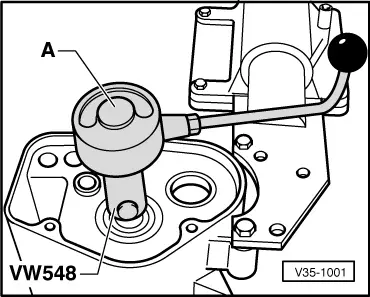

Checking friction moment |

|

|

|

→ A - Commercially available torque gauge 0 ... 600 Ncm

For new taper roller bearings the friction moment must be 80 ... 160 Ncm. For used taper roller bearings the friction torque must be at least 30 Ncm. Note: Lubricate bearings with gearbox oil before checking friction moment. |