Polo Mk3

|

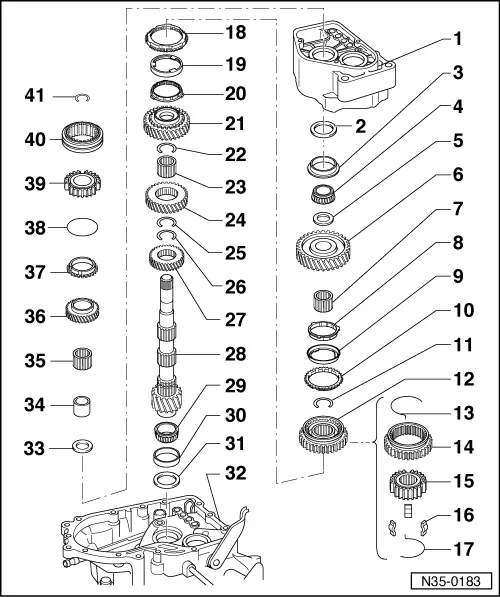

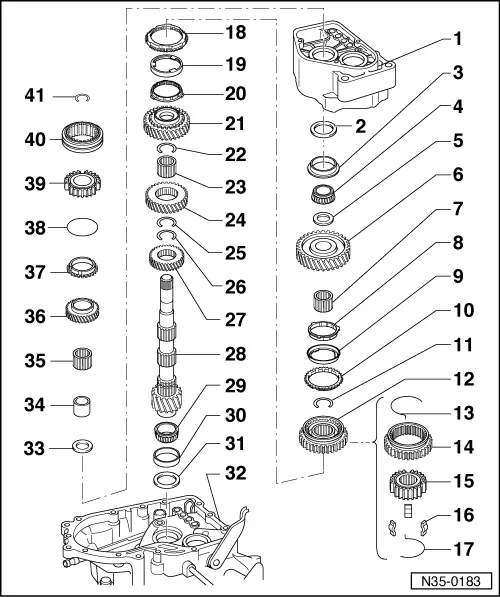

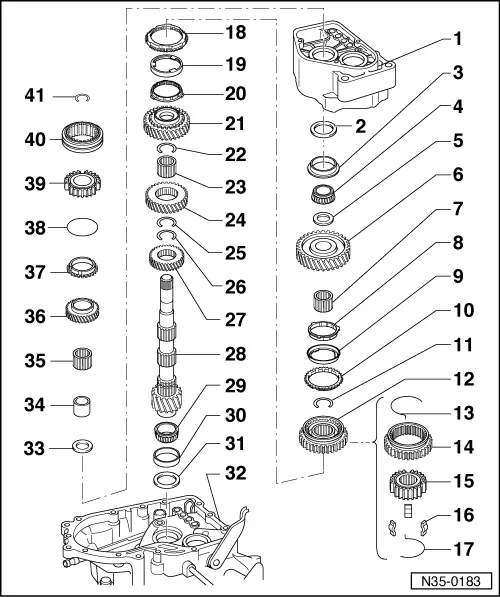

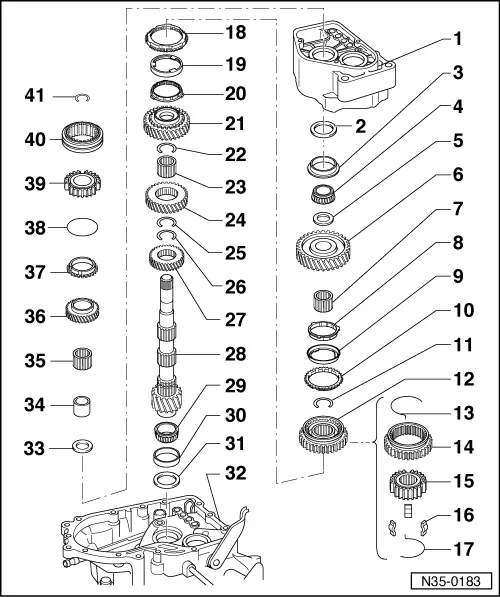

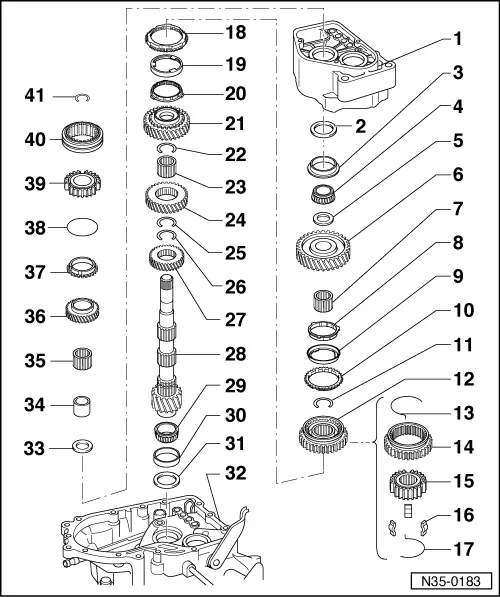

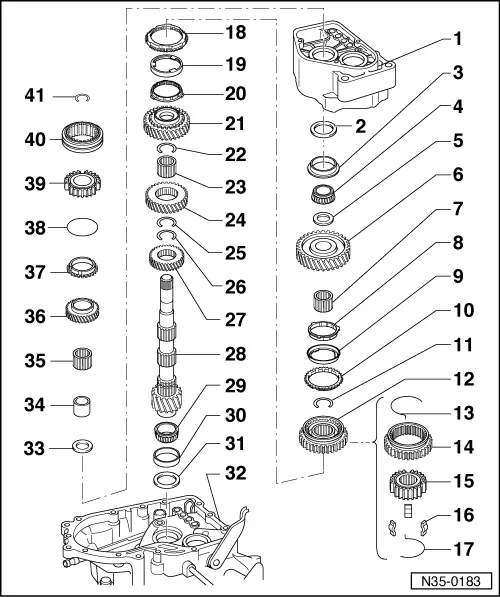

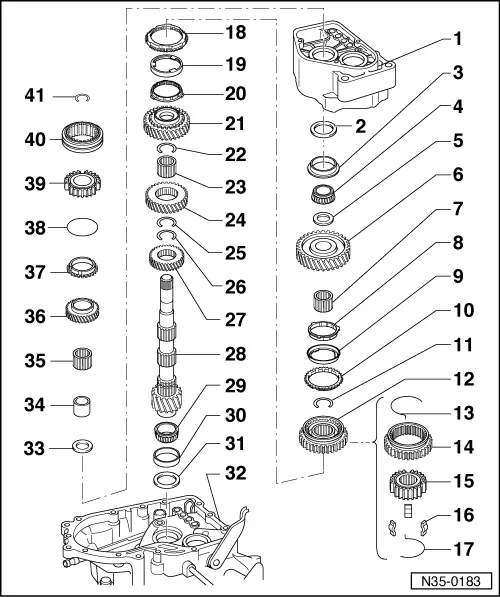

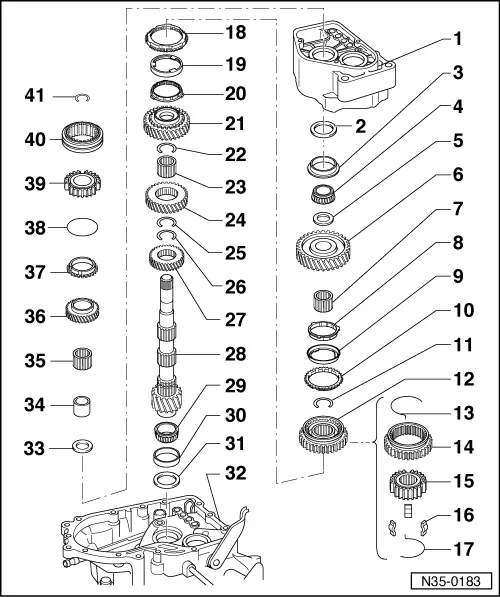

Dismantling and assembling output shaft

Dismantling and assembling output shaft

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

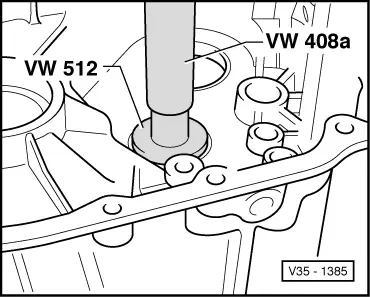

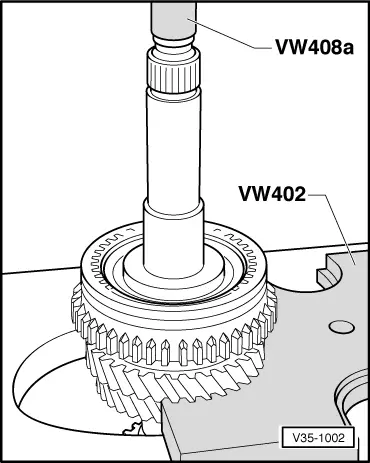

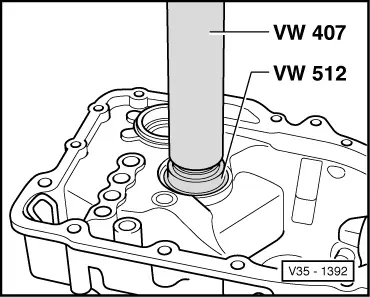

→ Fig.1 Pressing in taper roller bearing outer race |

|

|

|

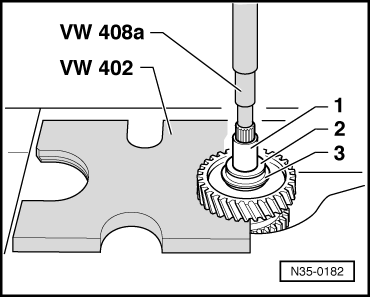

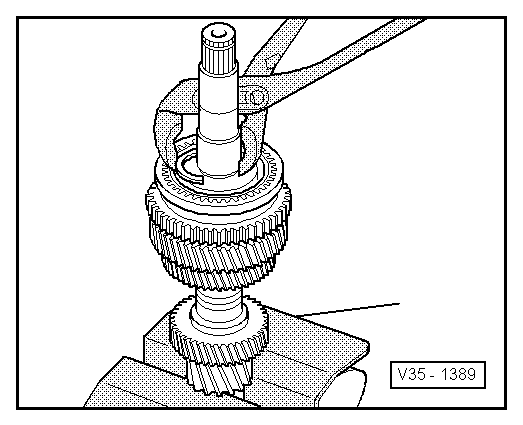

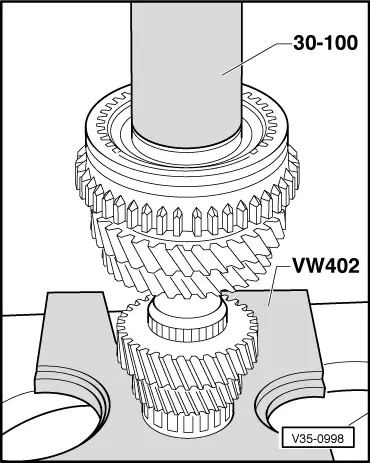

→ Fig.2 Pressing off 1st gear sliding wheel with sleeve -1-, thrust washer -2-, taper roller inner/outer race -3- |

|

|

|

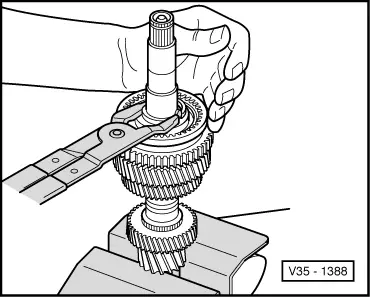

→ Fig.3 Pressing circlip out of groove Warning!

Prevent uncontrolled springing of circlip. Danger of accident! |

|

|

|

→ Fig.4 Pressing off 1st and 2nd gear locking collar and synchro-hub After removing securing ring press 2nd selector gear and locking collar/synchro-hub off together. |

|

|

|

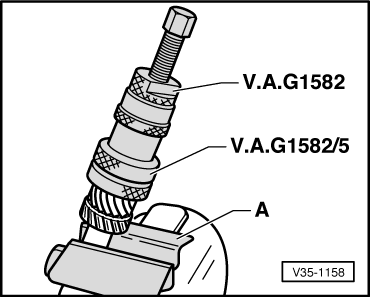

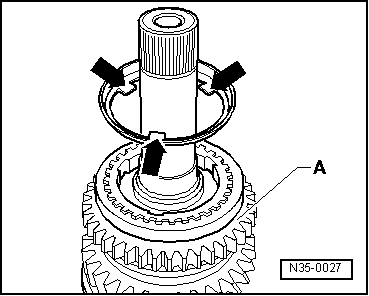

→ Fig.5 Pulling off small taper roller bearing inner race A - Vice clamps/vice

|

|

|

|

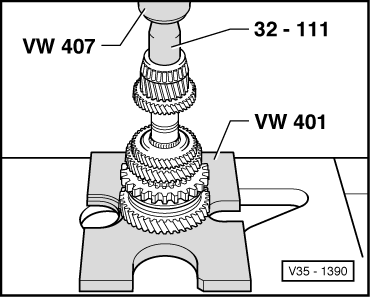

→ Fig.6 Pressing on taper roller bearing inner race |

|

|

|

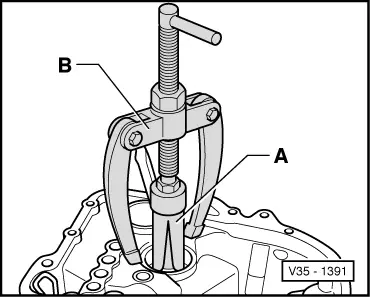

→ Fig.7 Pulling taper roller bearing outer race out of clutch housing A - Internal extractor, e.g. Kukko 21/6, 37 ... 46 mm B - Counter support, e.g. Kukko 22/2 |

|

|

|

→ Fig.8 Pressing in taper roller bearing outer race |

|

|

|

→ Fig.9 Inserting circlip |

|

|||||||

|

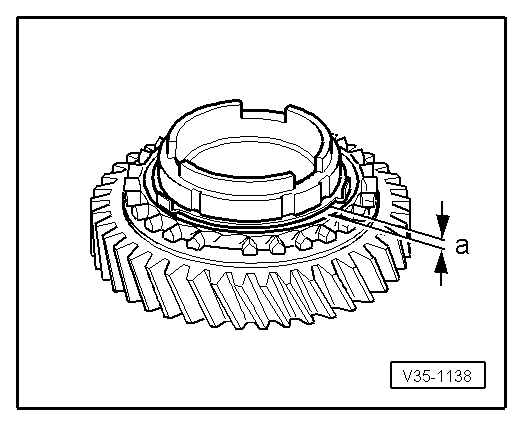

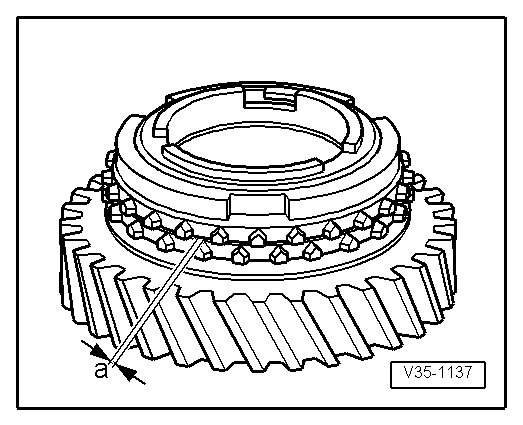

→ Fig.11 Checking 1st and 2nd gear synchro-ring for wear

|

|

|

|

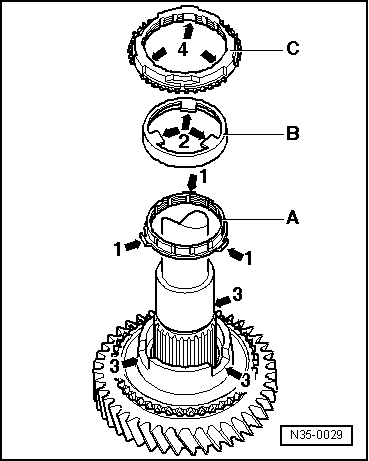

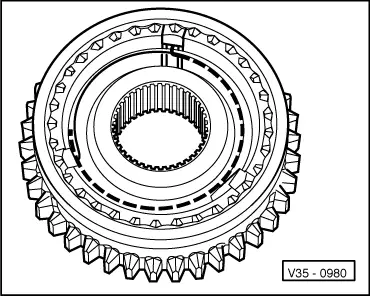

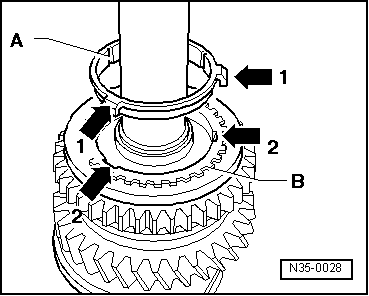

→ Fig.12 Installation position of outer-ring, inner ring and 2nd gear synchro-ring

The angled lugs (arrow 1) point towards outer ring -B-.

The lugs (arrow 2) engage in the selector gear recesses (arrow 3).

The grooves (arrow 4) engage in the inner ring -A- lugs (arrow 1). |

|

|

|

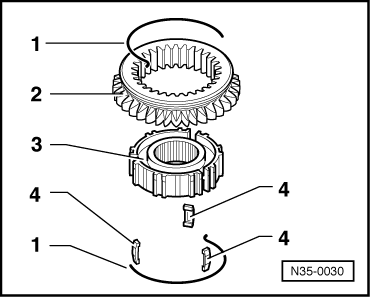

→ Fig.13 Dismantling and assembling 1st and 2nd gear synchro-hub and locking collar

The small recesses for locking pieces in synchro-hub and locking collar must align with one another. |

|

|

|

→ Fig.14 Assembling 1st and 2nd gear locking collar/synchro-hub The locking collar has been pushed over the synchro-hub.

|

|

|

|

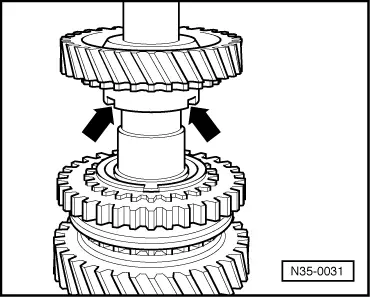

→ Fig.15 Pressing on locking collar/synchro-hub Installation position: Locking collar groove for selector fork towards 1st gear, the teeth for reverse gear towards 2nd gear. Turn synchro ring so that the grooves align with the locking pieces. |

|

|

|

→ Fig.16 Installation position for 1st gear outer-ring The lugs (arrows) face towards reverse gear -A-. |

|

|

|

→ Fig.17 Installation position synchro-ring -A- 1st gear (inner ring) The lugs (arrow 1) locate in the recesses (arrow 2) in the synchro-ring -B-. |

|

|

|

→ Fig.18 Installation position 1st selector gear The recesses in the shoulder (arrows) locate in the lugs of the outer-ring (arrows => Fig.16 ) |

|

|

|

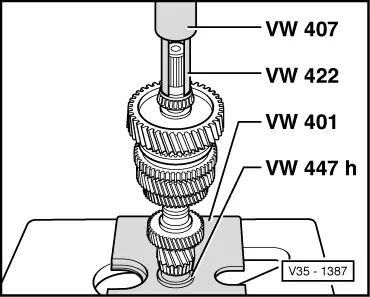

→ Fig.19 Pressing on taper roller bearing inner race |