Polo Mk3

|

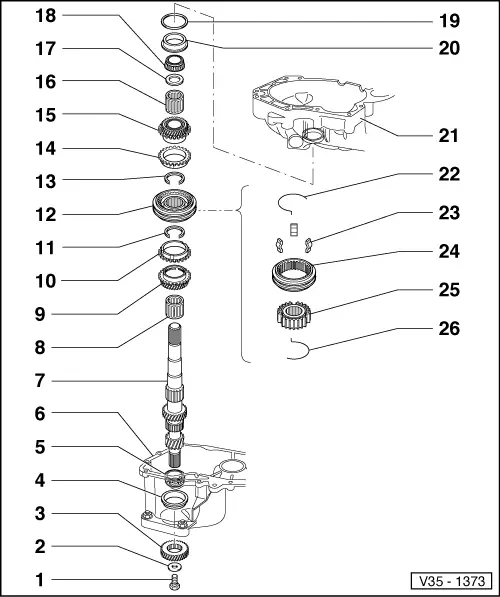

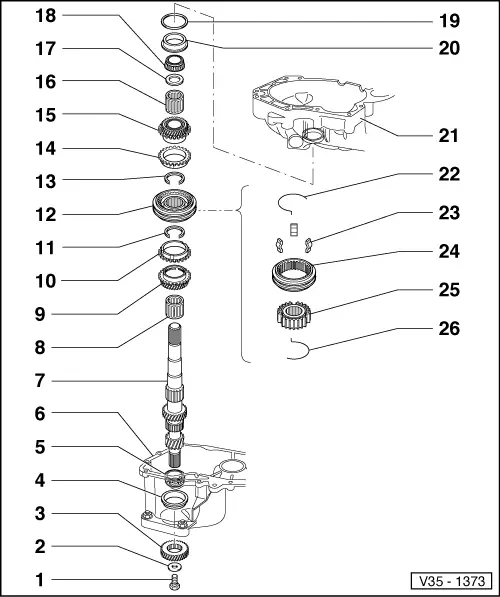

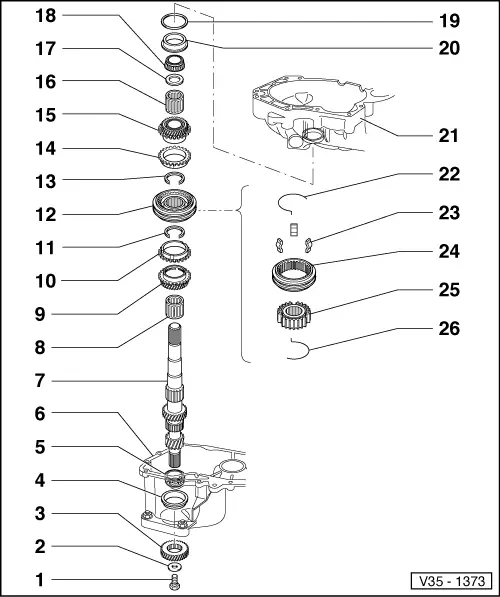

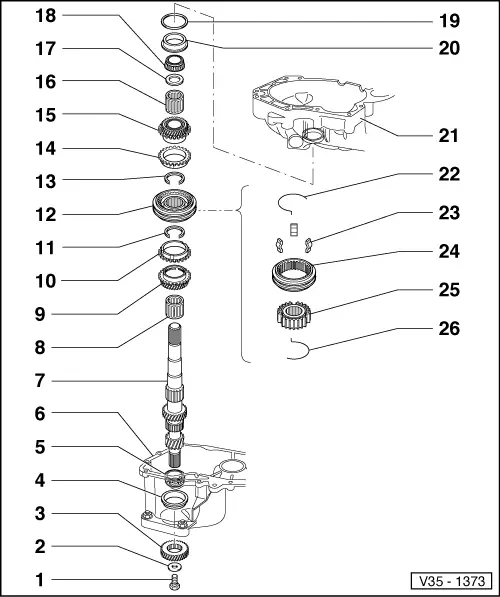

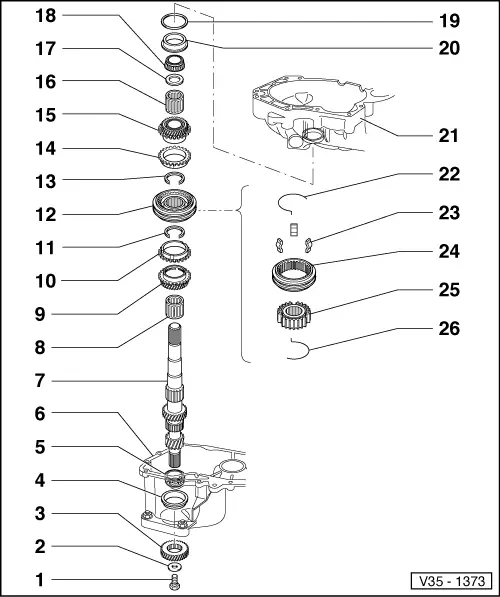

Dismantling and assembling input shaft

Dismantling and assembling input shaft

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

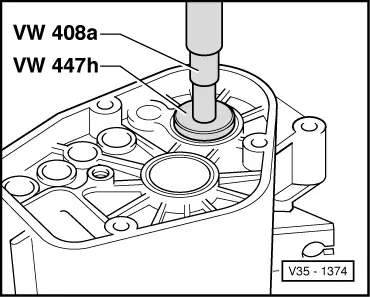

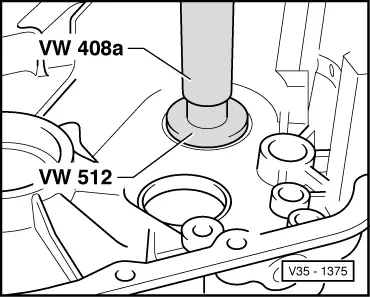

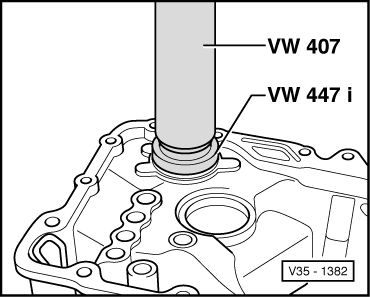

→ Fig.1 Pressing out taper roller bearing outer race |

|

|

|

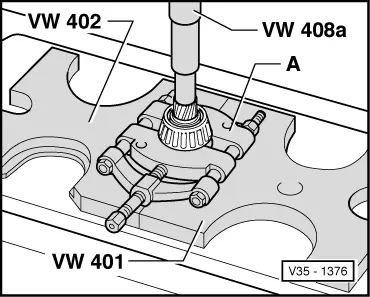

→ Fig.2 Pressing in taper roller bearing outer race |

|

|

|

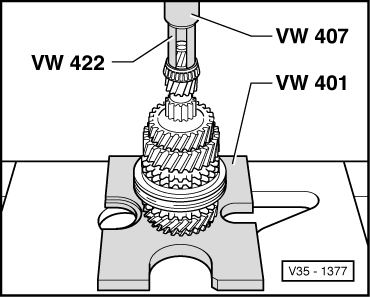

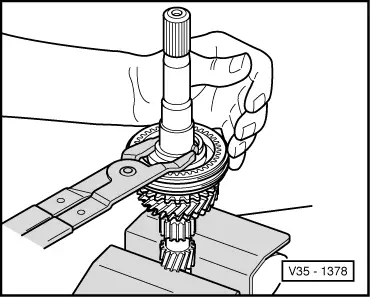

→ Fig.3 Pulling off small taper roller bearing inner race A - Separating device 22 ... 115 mm, e.g. Kukko 17/2 |

|

|

|

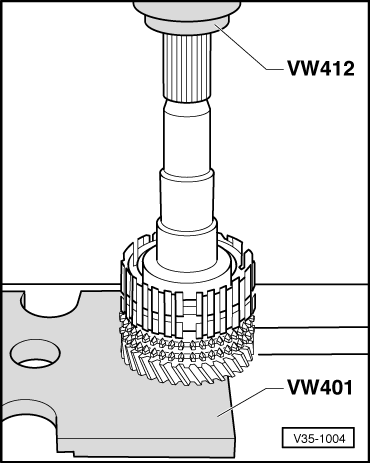

→ Fig.4 Pressing on small taper roller bearing inner race |

|

|

|

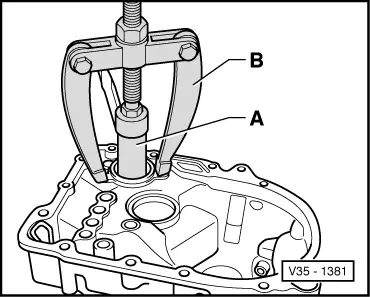

→ Fig.5 Pulling out taper roller bearing outer race A - Internal extractor 37 ... 46 mm, e.g. Kukko 21/6 B - Counter support, e.g. Kukko 22/2 |

|

|

|

→ Fig.6 Pressing in taper roller bearing outer race |

|

|

|

→ Fig.7 Pressing circlip out of groove Warning!

Prevent uncontrolled springing of circlip. Danger of accident! |

|

|

|

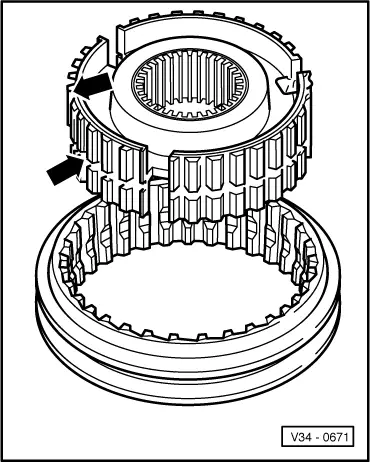

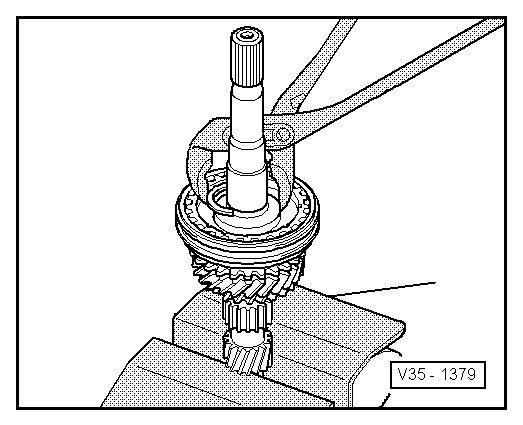

→ Fig.8 Pressing off synchro-hub

|

|

|

|

→ Fig.9 Inserting circlip |

|

|||||||

|

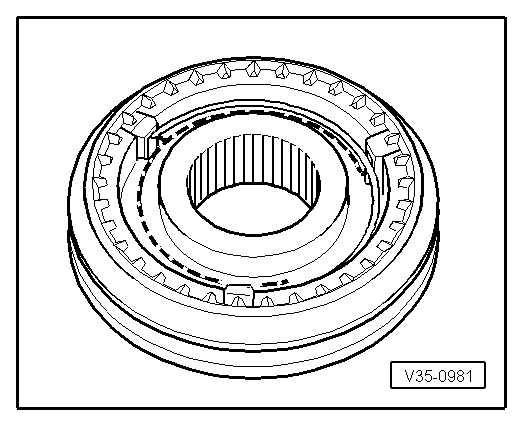

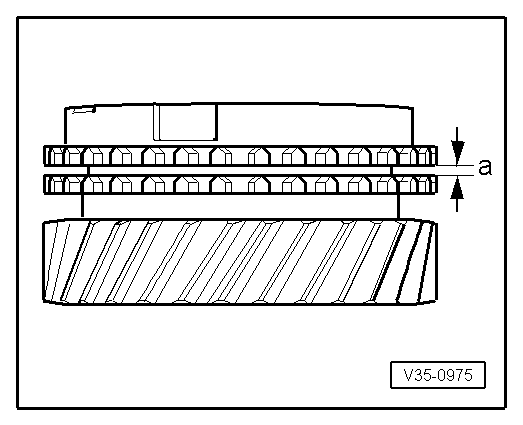

→ Fig.10 Checking synchro-ring for wear

|

|

|

|

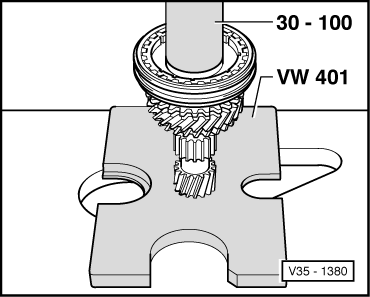

→ Fig.13 Pressing on 3rd and 4th gear synchro-hub with locking collar |