| –

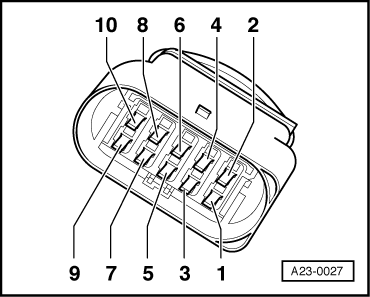

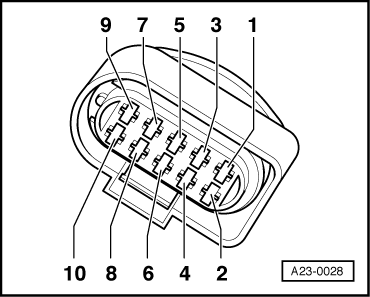

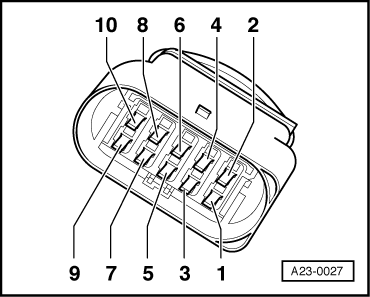

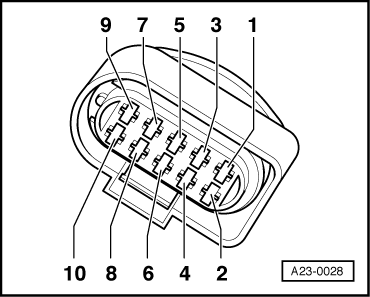

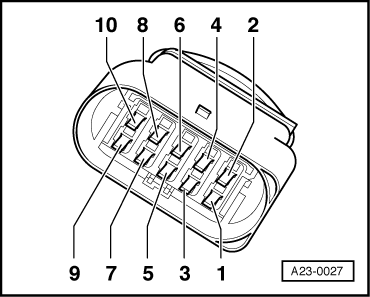

| Measure resistance between connector contacts 9+10. |

| Specification: 12.0…20.0 Ω |

| If the specification is not achieved: |

| –

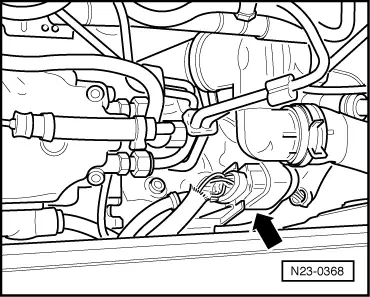

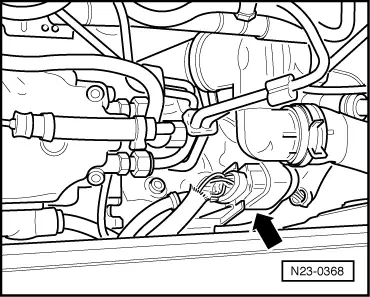

| Renew commencement of injection valve -N108- → Item. |

| –

| Read fault memory, if necessary, repair any faults and then clear fault memory → Chapter, Reading and clearing fault memory. |

| If the specification is attained: |

|

|

|