| –

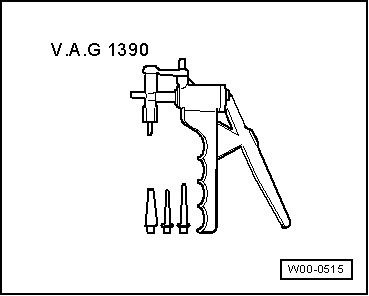

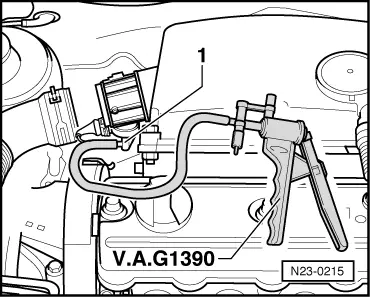

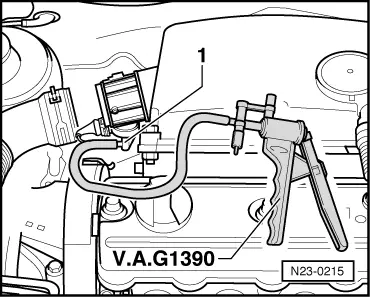

| Connect hand vacuum pump with accessories -V.A.G 1390/- to intake manifold flap vacuum unit -1-. |

| –

| Operate hand vacuum pump with accessories -V.A.G 1390/-. Intake manifold flap must close to stop and remain closed. |

| If the specification is not achieved: |

| –

| Check intake manifold flap change-over mechanics for freedom of movement. To do this, operate intake manifold flap by hand. |

| –

| Check that vacuum lines are connected correctly. |

| If a fault is found in the mechanical components: |

| –

| Renew inlet connection → Chapter, Removing and installing inlet connection. |

| If no fault is found in the mechanical components: |

| –

| Check variable intake manifold flap change-over valve -N239- → Chapter. |

|

|

|