| –

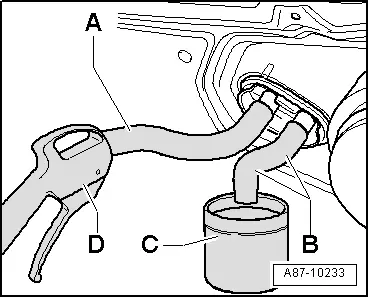

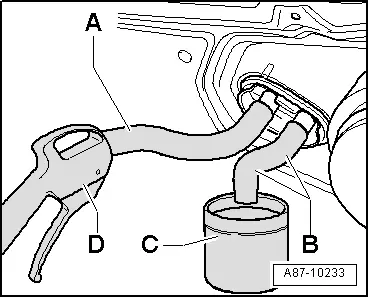

| Push a piece of hose -A- and -B- onto both connections to heat exchanger. |

| –

| Hold a container -C- under hose from lower connection -B-. |

| –

| Using a compressed air gun -D-, carefully blow coolant out of heat exchanger into container -C- via hose -A-. |

| –

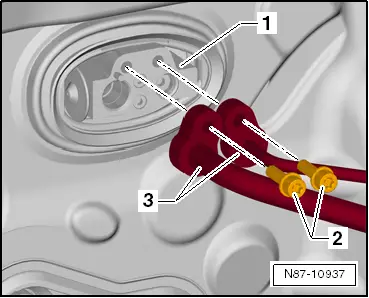

| Extract refrigerant, e.g. with air conditioner service station -VAS 6007A- or later model. |

WARNING | Danger from refrigerant escaping under pressure! |

| Freezing of skin and other body parts. |

| l

| Evacuate the refrigerant and then open the refrigerant circuit immediately. |

| l

| If more than 10 minutes have elapsed since evacuation and the coolant circuit has not been opened, evacuate the refrigerant again. Pressure builds up in the coolant circuit as a result of secondary evaporation. |

|

|

|

|

Note

Note

Note

Note

WARNING

WARNING