A3 Mk1

|

Removing and installing engine

Installing

Special tools and workshop equipment required

Procedure

Installation is carried out in the reverse order to removal, noting the following: Notes:

=> Parts List

|

|

|

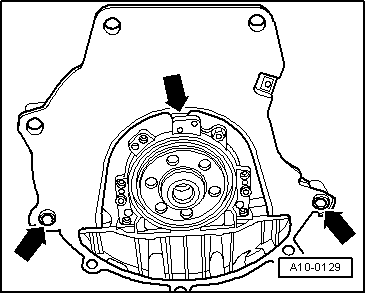

Vehicles with manual gearbox:

Notes:

|

|

||||||||||||||||

|

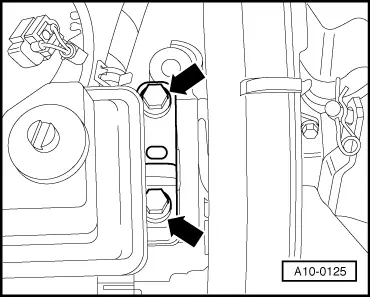

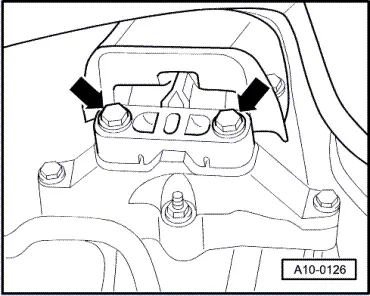

→ Engine/gearbox mountings (manual gearbox)

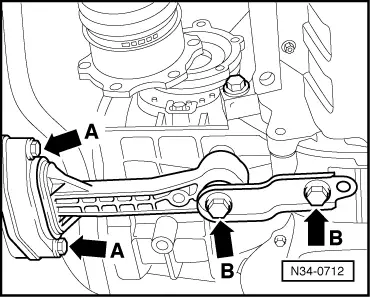

1) Bolt with threaded pin M8 A: Centring sleeves |

|

|

|

|

|

|

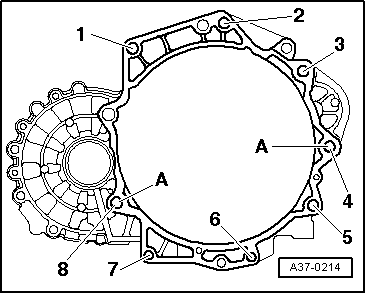

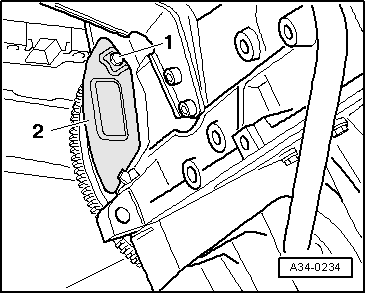

Vehicles with automatic gearbox:

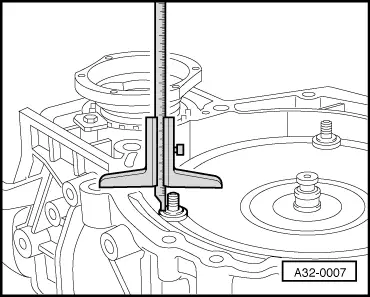

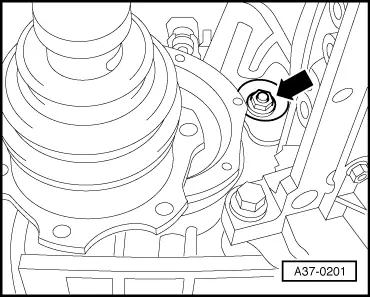

=> Parts List → If the torque converter is correctly installed, the depth between the contact surfaces at the bottom of the studs on the torque converter and the contact surface of the torque converter bell housing is about 22 mm. If the torque converter has not been completely inserted, this distance will be approx. 10 mm. Important

If the torque converter is not installed correctly, the torque converter drive plate or the ATF pump will be seriously damaged when the gearbox is joined to the engine. |

|

|

Notes:

|

|

||||||||||||||||

|

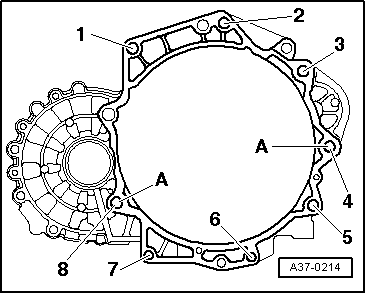

→ Fastening engine to gearbox in vehicles with automatic gearbox

1) Bolt with threaded pin M8 A: Centring sleeves |

|

|

|

All models:

|

|

|

Note: The bolts are tightened to final torque only after adjusting the engine mounting .

=> Running Gear, FWD and 4WD; Repair group 40 Note: Before further assembly carry out the installation of the drive shafts.

|

|

||||||||||||||||||||||||||||||||||

Vehicles with manual gearbox:

=> 5-speed Manual Gearbox 02K; Repair group 30; Servicing clutch release mechanism

=> 5-speed Manual Gearbox 02K; Repair group 34; Servicing shift mechanism All models: Vehicles with throttle cable:

All models:

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations Notes:

=> Radio, Telephone and Navigation System; Repair group 91

=> Simos Fuel Injection and Ignition System; Repair group 24 Notes:

Important

Do not use charging unit for boost starting. There is danger of damaging the vehicle control units. Tightening torques

1) 90°corresponds to a quarter of a turn 2) Replace nuts and bolts | ||||||||||||||||||||||||||||||||||