A3 Mk2

| Removing gearbox - vehicles with V6 engine |

| Special tools and workshop equipment required |

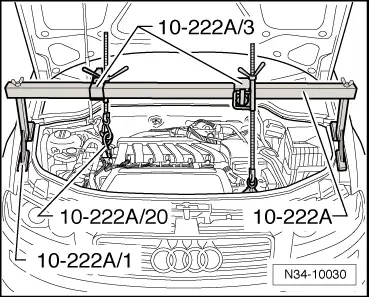

| t | Support bracket -10 - 222 A- |

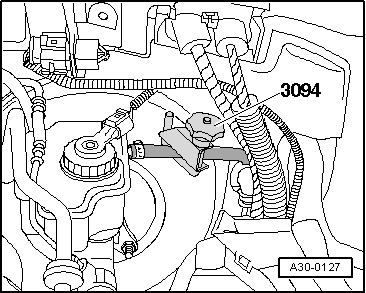

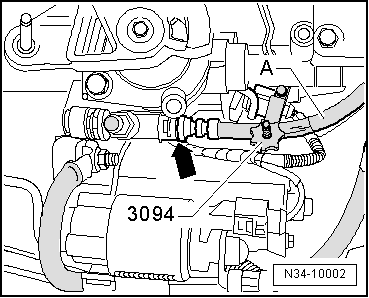

| t | Hose clamps, up to 25 mm -3094- |

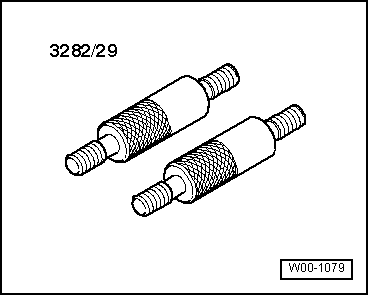

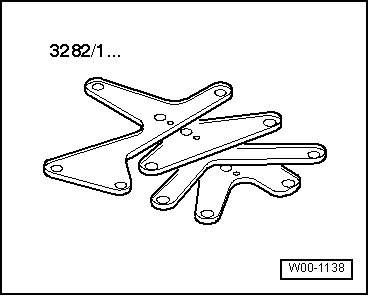

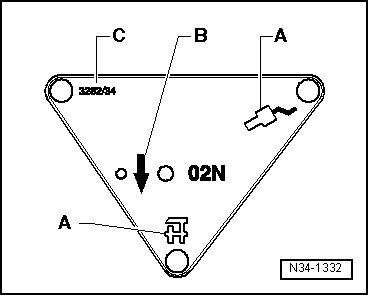

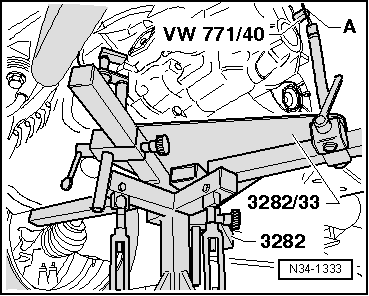

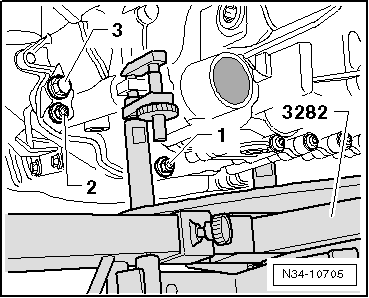

| t | Gearbox support -3282- |

| t | Adapter -VW 771/40- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution