| –

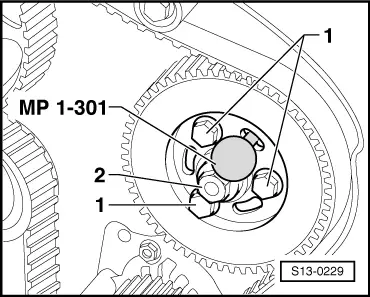

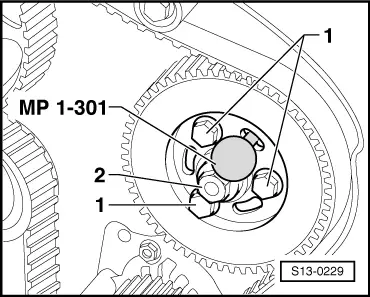

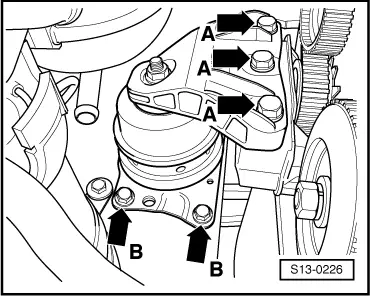

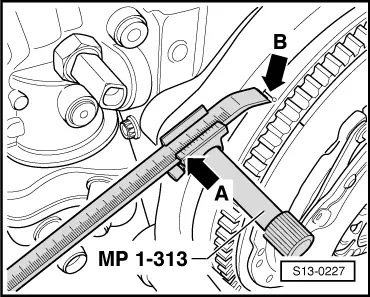

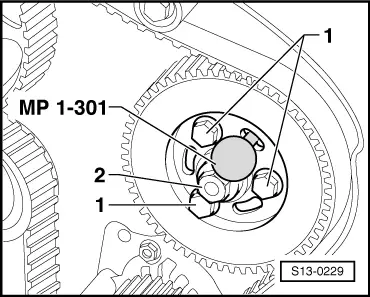

| Lock injection pump gear with locking pin -MP1-301-. |

Note | If the injection pump gear cannot be correctly locked, first slacken the toothed belt. |

| –

| Determine the version of the injection pump gear Pos. 18. |

| Injection pump gear 038 130 111 A |

| –

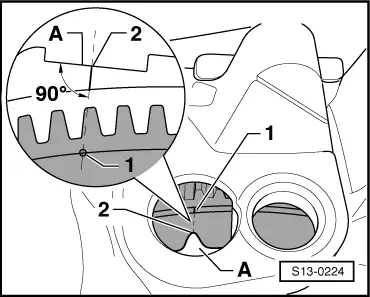

| Release the fixing bolts -1- of the injection pump gear and loosely screw the new bolts to the hub. |

| Injection pump gear 038 130 111 B |

| –

| Loosen fixing bolts -1- of the injection pump gear. |

| Proceed as follows for both injection pump gears |

Note | The nut -2- for the hub must never be loosened. Basic setting up of the injection pump cannot be undertaken using normal workshop tools. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note