Octavia Mk1

| 1 - | 10 Nm |

| 2 - | Inlet camshaft |

| q | Inspecting axial play → Chapter |

| q | Removing and installing camshafts → Chapter |

| 3 - | Drive chain |

| q | check for wear |

| q | mark running direction (installed position) before removing → Chapter |

| 4 - | Camshaft adjuster |

| q | with camshaft adjustment valve 1 -N205- |

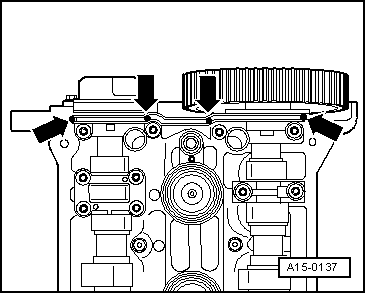

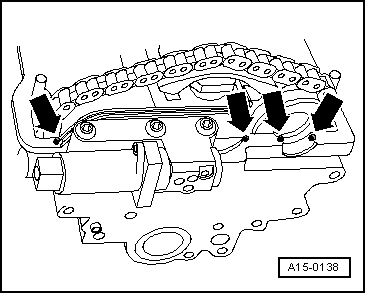

| q | Seal the joints between the camshaft adjuster/cylinder head → Fig. |

| q | removing and installing → Chapter |

| 5 - | rubber metal seal |

| q | replace → Chapter |

| 6 - | Cylinder head |

| q | removing and installing → Chapter |

| q | reworking valve seats → Chapter |

| q | inspecting valve guides → Chapter |

| q |

| 7 - | Exhaust valve |

| q | with a sodium filling |

| q | Observe specifications for disposing of the valves with a sodium filling → Chapter |

| q | do not rework, only grinding in is permissible |

| q | Valve dimensions → Chapter |

| q | inspecting valve guides → Chapter |

| q | reworking valve seats → Chapter |

| 8 - | Inlet valve |

| q | do not rework, only grinding in is permissible |

| q | Valve dimensions → Chapter |

| q | inspecting valve guides → Chapter |

| q | reworking valve seats → Chapter |

| 9 - | Gasket ring |

| q | for inlet camshaft |

| q | replace → Chapter |

| q | pay attention to different version → Chapter |

| 10 - | Trim for hall sender |

| q | check fitting position: |

| Insert the peg in the notch of the camshaft |

| 11 - | Washer |

| q | with cone |

| q | Check fitting position |

| 12 - | 25 Nm |

| 13 - | Hall sender -G40- |

| 14 - | 10 Nm |

| 15 - | 65 Nm |

| q | to release and tighten use counterholder -MP1-216 (3036)- |

| 16 - | Camshaft sprocket |

| q | for exhaust camshaft |

| q | check fitting position: |

| the small stay on the camshaft sprocket points outwards and the TDC marking on the cylinder 1 is visible from the front |

| 17 - | Gasket ring |

| q | for exhaust camshaft |

| q | replace → Chapter |

| q | pay attention to different version → Chapter |

| 18 - | Valve stem seal |

| q | replace → Chapter |

| 19 - | Valve spring |

| q | removing and installing → Chapter |

| 20 - | Valve spring retainer |

| 21 - | Valve collets |

| 22 - | Hydraulic bucket tappets |

| q | do not interchange |

| q | oil contact surfaces |

| q | lay aside with contact surface facing down |

| q | before installing check axial play of the camshaft → Chapter |

| q | check → Chapter |

| q | removing and installing → Chapter |

| 23 - | Bearing cap/inlet camshaft |

| q | must be positioned on the dowel sleeves in the cylinder head |

| q | Check fitting position |

| q | order of installation → Chapter |

| 24 - | Double bearing cover |

| q | must be positioned on the dowel sleeves in the cylinder head |

| q | Seal the joints between the double bearing cap/cylinder head → Fig. |

| q | apply sealant - D 454 300 A2- lightly on the sealing surface before installing → Chapter |

| 25 - | Bearing cover/exhaust camshaft |

| q | must be positioned on the dowel sleeves in the cylinder head |

| q | Check fitting position |

| q | order of installation → Chapter |

| 26 - | Exhaust camshaft |

| q | removing and installing → Chapter |

|

|

|

|

Note

Note