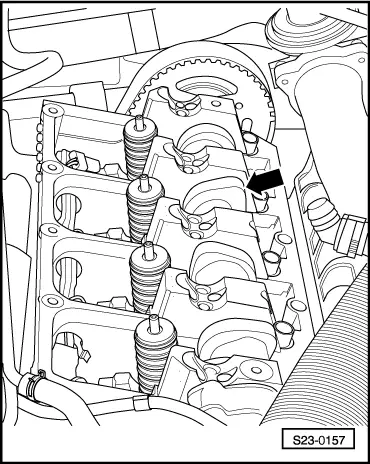

| –

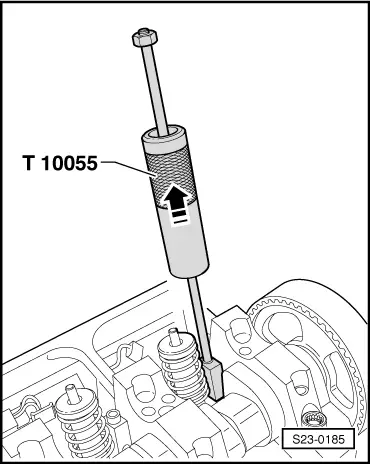

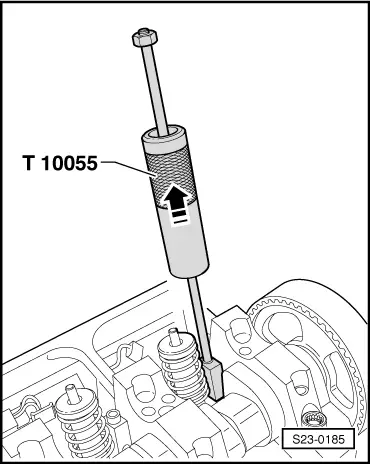

| Insert extractor -T10055- in direction of the camshaft instead of the clamping pad in the slot of the unit injector. |

| –

| Remove the unit injector through movements of the sleeve at the nut up to the stop in -direction of arrow-. |

Note | Do not interchange the unit injectors, if necessary mark the assignment to each cylinder. |

Note | t

| Pay attention to the different version of the unit injector, adjusting screw and ball pin. When replacing the unit injector, the versions are to be replaced individually. |

| t

| The associated adjusting screws in the valve-lever should be replaced when a new unit injector is being installed. |

| t

| For any work procedure involving an adjustment of the unit injector it is necessary to clean the adjusting screw in the valve lever and also the ball pin of the unit injector and to check them for traces of wear. If there is any wear replace the ball pin and the adjusting screw. |

| t

| On the old version of the pump-nozzle drive grease the contact surfaces between ball pins and adjusting screw using grease -G 000 100-. |

| t

| New unit injectors are supplied with O-rings, heat-protection seal and circlip. |

| –

| Before installing the unit injector check the correct position of all three O-rings, heat-protection seal and the circlip. |

Note | The O-rings must not be twisted in the slots. |

| –

| Oil the O-rings and place the unit injector with the greatest of care into the cylinder head. |

| –

| Slide unit injector into the cylinder head seat up to the stop by exerting a uniform pressure. |

| –

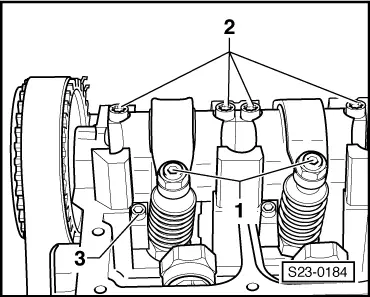

| Place the clamping pad in the side slot of the unit injector. |

Note | If the unit injector is not perpendicular to the clamping pad the fixing screw may loosen and cause damage to the unit injector or cylinder head. |

| Align the unit injector as follows: |

| –

| Screw the clamping pad with the new fixing screw until the unit injector can still easily be turned. |

| –

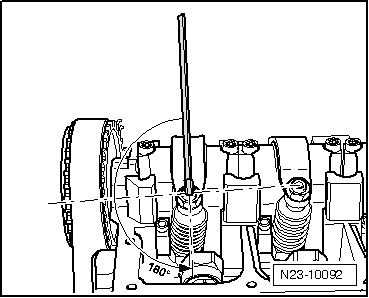

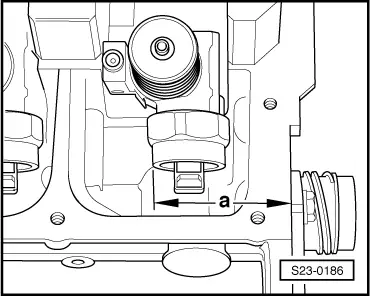

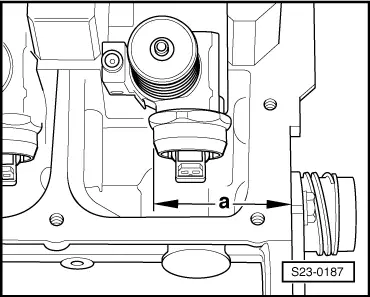

| Set unit injector at a right angle to the bearing shell of the camshaft. |

| –

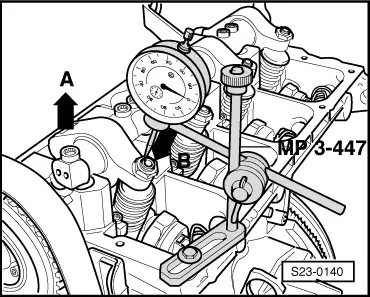

| Using a caliper gauge, check dimension -a- from the outer side of the cylinder head to the cylinder surface of the unit injector. |

Note | Sliding use of the unit injectors with a new solenoid valve nut. A mixed lining is admissible when one maintains dimension -a-. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note Note

Note Note

Note

Note

Note