A3 Mk2

| Dismantling and assembling output shaft for 1st - 4th gear |

| Special tools and workshop equipment required |

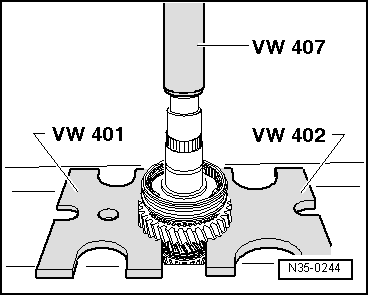

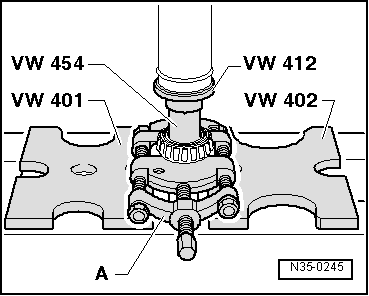

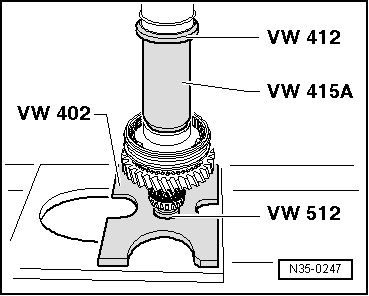

| t | Thrust plate -VW 401- |

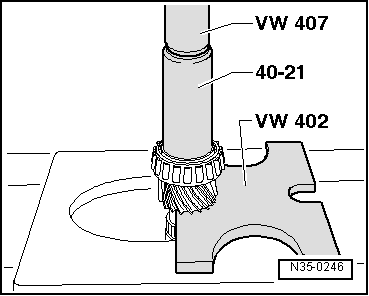

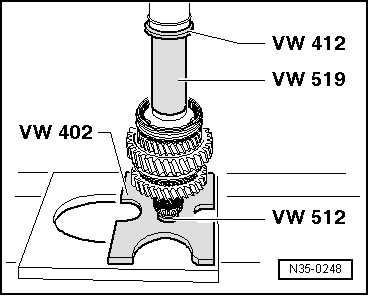

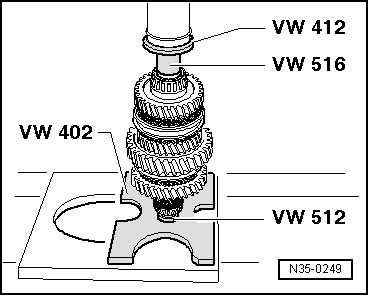

| t | Thrust plate -VW 402- |

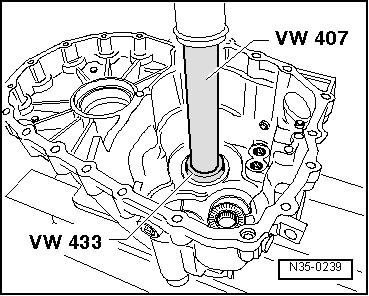

| t | Press tool -VW 407- |

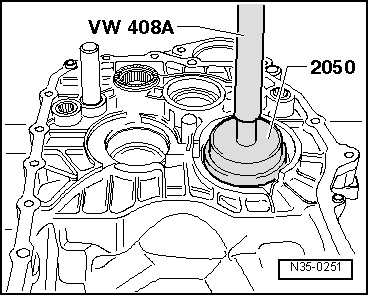

| t | Press tool -VW 408A- |

| t | Press tool -VW 412- |

| t | Tube -VW 415A- |

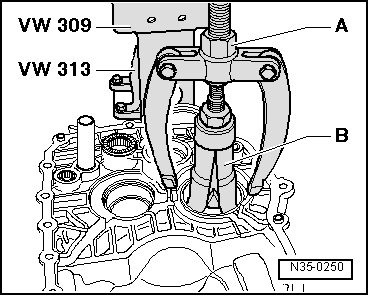

| t | Support plate -VW 309- |

| t | Support clamp -VW 313- |

| t | Gearbox support -VW 353- |

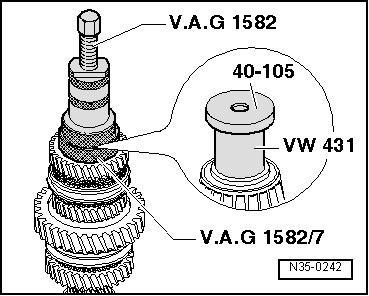

| t | Press tool -VW 431- |

| t | Press tool -VW 433- |

| t | Press tool -VW 454- |

| t | Thrust pad -VW 512- |

| t | Tube -VW 516- |

| t | Tube -VW 519- |

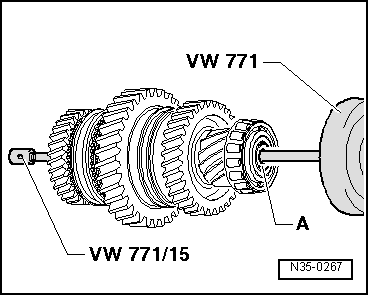

| t | Multi-purpose tool -VW 771- |

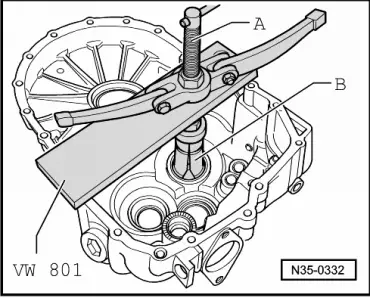

| t | Support plate -VW 801- |

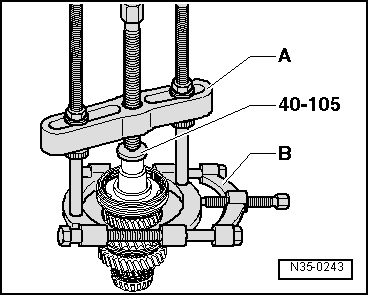

| t | Thrust plate -40 - 105- |

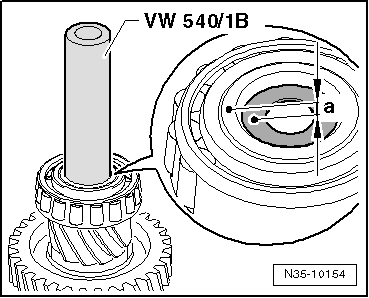

| t | Sleeve from engine and gearbox support supplement -VW 540/1 B- |

| t | Drift sleeve -40 - 20- |

| t | Press tool -40 - 21- |

| t | Thrust piece -2050- |

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/7- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

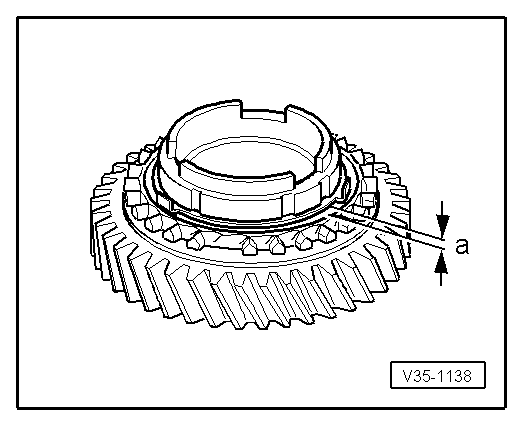

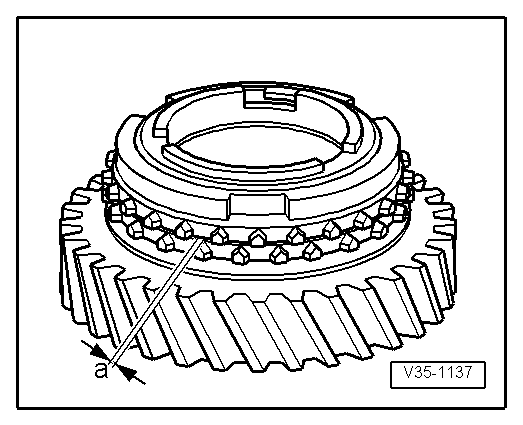

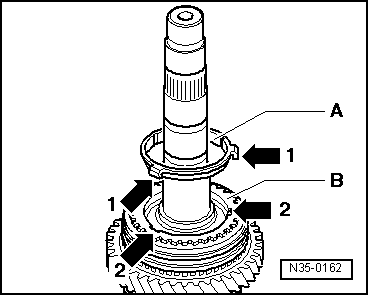

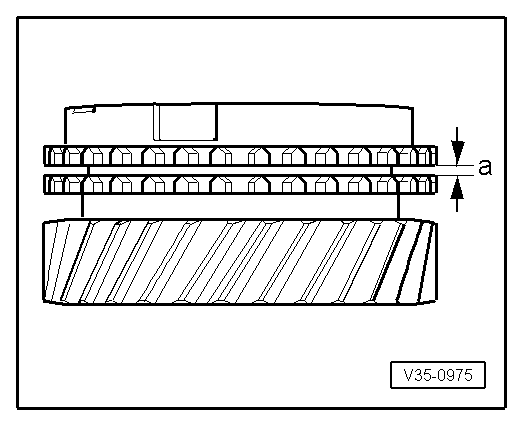

| Gap -a- | Installation depth | Wear limit |

| 1st, 2nd and 3rd gear | 0.75...1.25 mm | 0.3 mm |

|

|

| Gap -a- | Installation depth | Wear limit |

| 1st, 2nd and 3rd gear | 1.2...1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

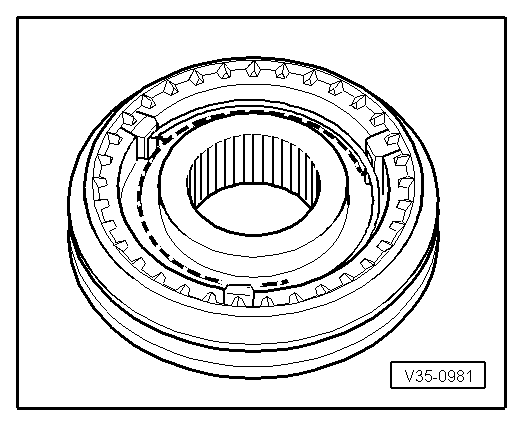

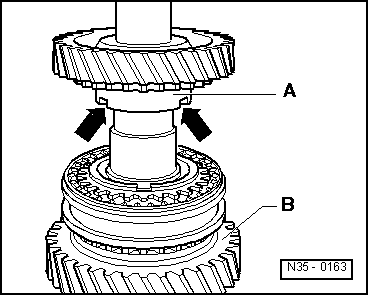

| Gap -a- | Installation depth | Wear limit |

| 4th gear | 1.0...1.7 mm | 0.5 mm |

|

|

|

|

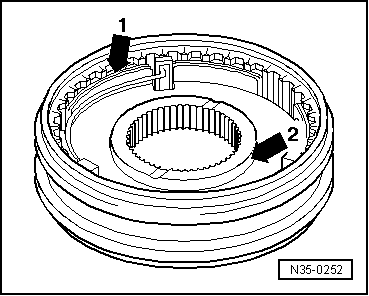

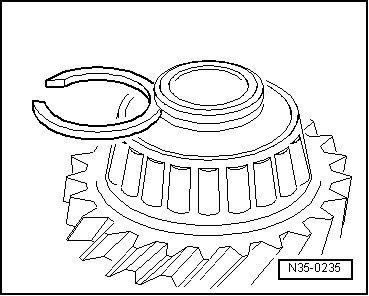

| Circlip thickness (mm) | ||

| 1.79 | 1.83 | 1.86 |

| 1.89 | 1.92 | 1.95 |

| 1.98 | ||

|

|

|

|