A3 Mk2

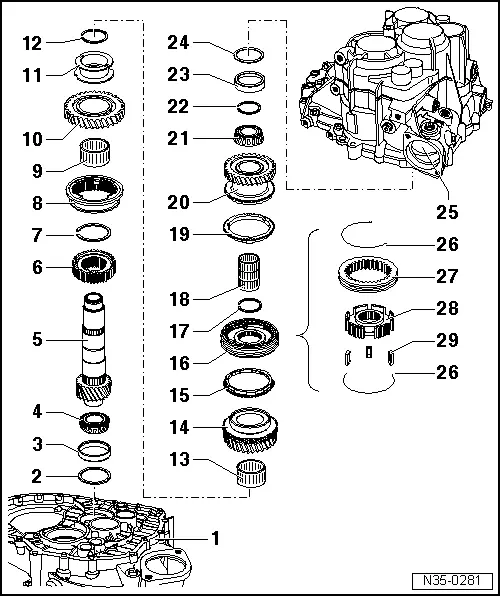

| Exploded view - output shaft for 5th, 6th and reverse gear |

Note

Note| t | Mounting gearbox on assembly stand → Chapter |

| t | Carry out output shaft adjustment → Chapter if the output shaft or tapered roller bearings have been renewed . |

| t | Refer to → Electronic parts catalogue when installing new gear wheels or a new output shaft. |

| t | Always renew both tapered roller bearings together. |

| 1 - | Clutch housing |

| 2 - | Shim |

| q | 0.65 mm thick |

| 3 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 4 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 5 - | Output shaft for 5th, 6th and reverse gear |

| q | Adjusting → Chapter |

| 6 - | Reverse gear synchronising hub |

| q | Pressing off → Fig. |

| q | Installation position → Fig. |

| q | Pressing on → Fig. |

| 7 - | Circlip |

| 8 - | Reverse gear locking collar |

| q | With synchro-ring |

| 9 - | Needle bearing |

| q | For reverse selector gear |

| 10 - | Reverse selector gear |

| 11 - | Sleeve |

| q | Press off with reverse selector gear → Fig. |

| q | Installation position: Wide shoulder of sleeve faces towards reverse selector gear |

| q | Pressing on → Fig. |

| 12 - | Circlip |

| 13 - | Needle bearing |

| q | For 6th gear |

| 14 - | 6th speed selector gear |

| 15 - | 6th gear synchro-ring |

| q | Checking for wear → Fig. |

| 16 - | Locking collar with synchronising hub for 5th and 6th gear |

| q | Press off together with 6th speed selector gear after removing circlip → Item → Fig. |

| q | Dismantling → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. and → Fig. |

| q | Pressing on → Fig. |

| 17 - | Circlip |

| 18 - | Needle bearing |

| q | For 5th gear |

| 19 - | 5th gear synchro-ring |

| q | Checking for wear → Fig. |

| 20 - | 5th speed selector gear |

| 21 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 22 - | Circlip |

| q | When tapered roller bearing → Item or output shaft → Item are renewed: determine thickness of required circlip → Fig. |

| 23 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 24 - | Shim |

| q | Determining thickness → Chapter |

| 25 - | Gearbox housing |

| 26 - | Spring |

| q | Installation position → Fig. |

| 27 - | Locking collar |

| 28 - | Synchronising hub |

| 29 - | Locking pieces (3x) |

| q | Installation position → Fig. |