Freelander Service Procedures

DRIVESHAFTS

REPAIRS

47-7

10. With assistance pull hub assembly outwards

and release drive shaft outer joint from hub

assembly.

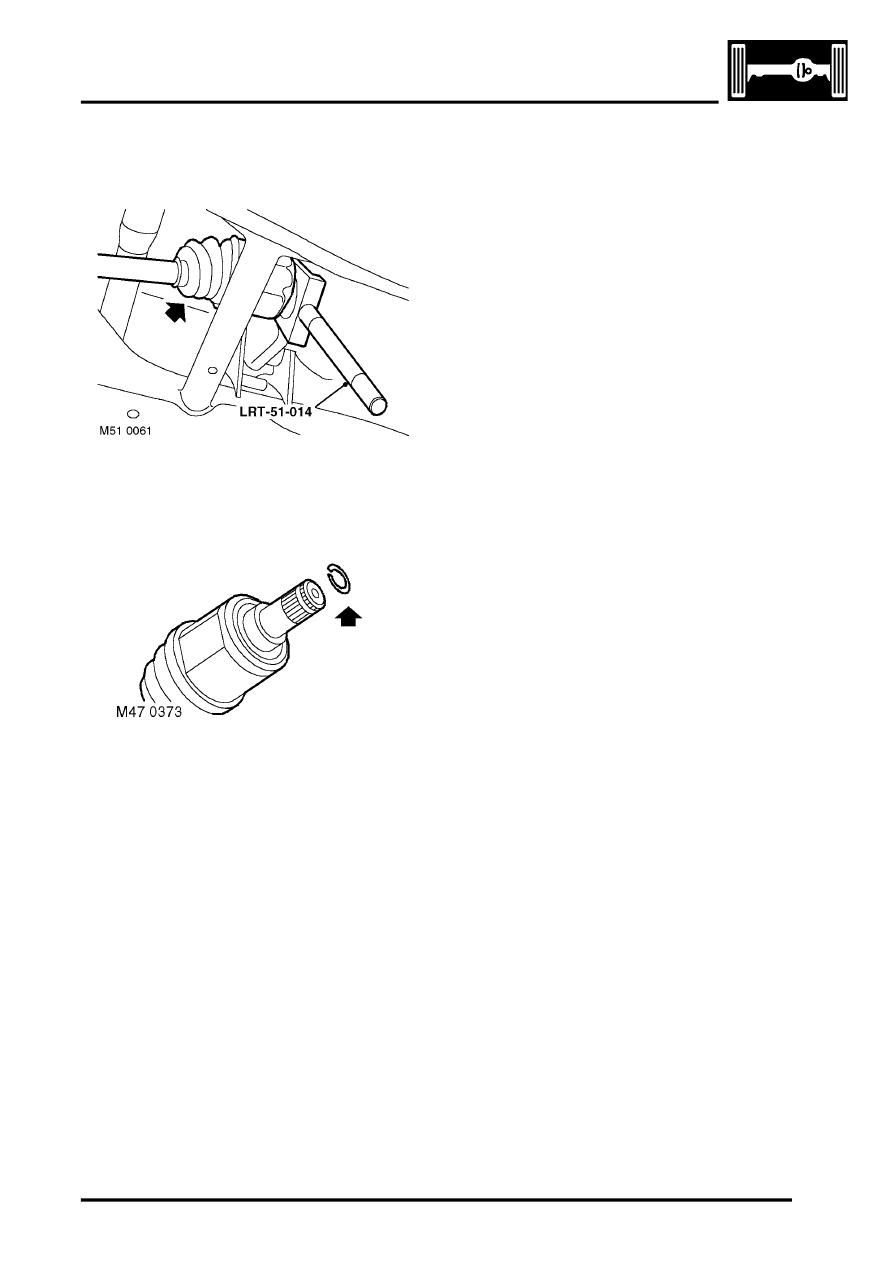

11. Taking care not to damage 'Flinger', release

drive shaft inner joint from differential using

LRT-51-014 and remove drive shaft.

12. Remove and discard drive shaft circlip.

Refit

1. Inspect differential seal, renew if worn or

damaged.

2. Clean ends of drive shaft and locations in hub

and differential.

3. Lubricate oil seal running surface with

transmission oil.

4. Fit new circlip to drive shaft.

5. Fit drive shaft to differential and push fully

home.

CAUTION: Pull the drive shaft to ensure the

circlip is fully engaged and retains the shaft.

6. With assistance fit drive shaft to hub.

7. Fit new drive shaft nut but do not tighten at this

stage.

8. Fit nut, bolt and dynamic damper to adjustable

transverse link and tighten to 120 Nm (89 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with the weight of the vehicle on the

suspension.

9. Fit nut and bolt to fixed transverse link and

tighten to 120 Nm (89 lbf.ft).

10. Fit spacer, nut and bolt to trailing link and

tighten to 120 Nm (89 lbf.ft).

11. Fit new drive shaft nut and tighten to 400 Nm

(295 lbf.ft). Stake nut to shaft.

12. Check and top up oil level.

13. Fit road wheel(s) and tighten nuts to 115 Nm 85

lbf.ft).

14. Remove stands and lower vehicle.

15. Connect battery earth lead.