Freelander Service Procedures

ENGINE - K SERIES KV6

OVERHAUL 12-3-105

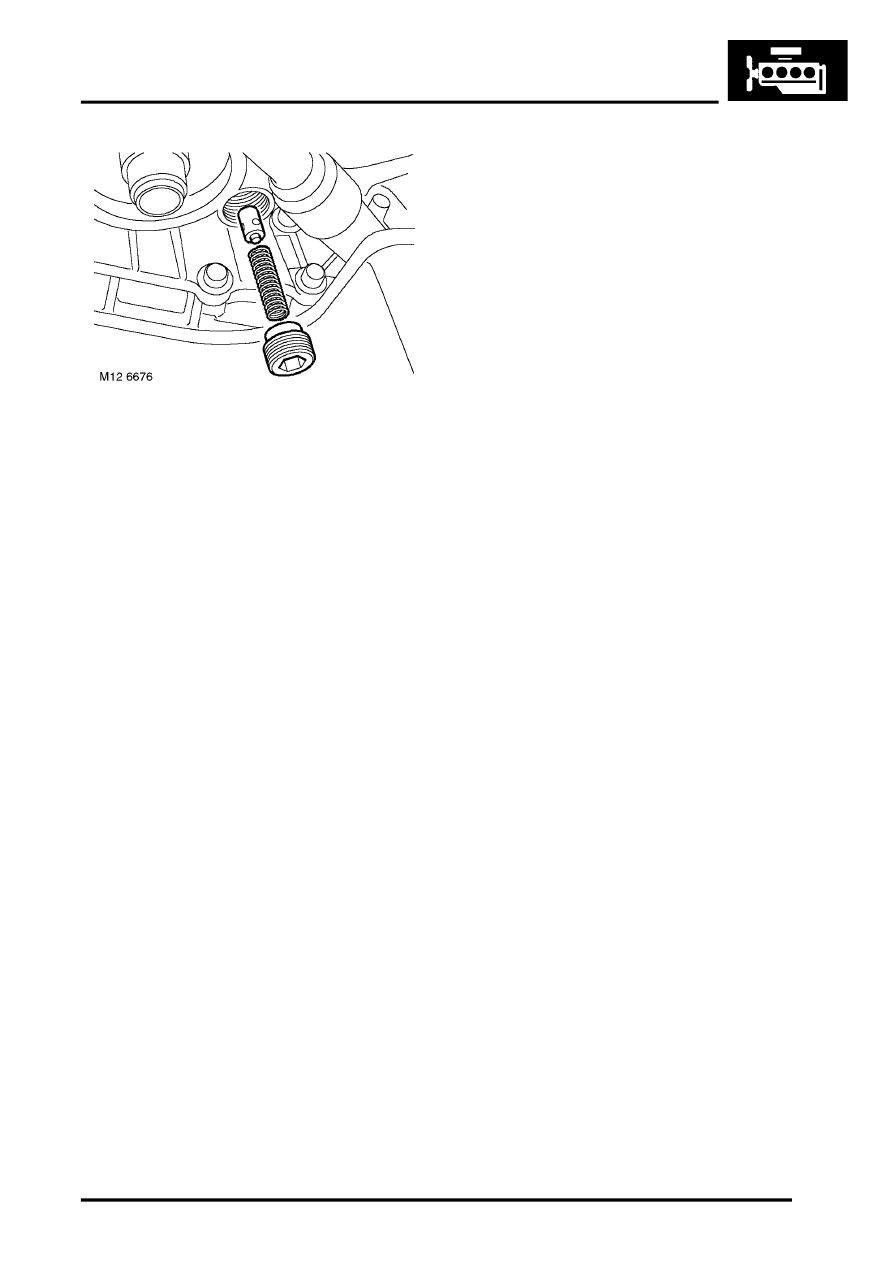

3. Remove oil pressure relief valve plug.

Note: If a hexagonal plug and sealing washer

are fitted, discard washer.

4. Remove spring and valve.

5. Check that valve and bore are free from scoring

and corrosion.

Note: Light corrosion may be removed using

grade 600 emery cloth soaked in engine oil.

6. Check free length of spring.

7. Check that valve slides freely in bore.

CAUTION: If valve is scored, renew relief

valve as an assembly. If valve bore is

scored, renew oil pump as an assembly.

Reassembly

1. Clean cover plate and mating face of cylinder

block; ensure bolt holes are clean and dry.

2. Clean running surface on crankshaft.

3. Remove all traces of sealant from relief valve

plug, Torx screws and tapped holes in pump

body.

CAUTION: Do not use a tap.

4. Lubricate relief valve, spring and bore with

clean engine oil.

5. Fit relief valve and spring.

6. If a hexagonal plug and sealing washer were

fitted, fit new sealing washer to plug.

7. Apply sealant, Part No. STC 50552 to plug

threads; fit plug and tighten to 25 Nm (18 lbf.ft).

8. Lubricate pump rotors and recess with clean

engine oil.

9. Fit inner and outer rotors ensuring that

identification mark on outer rotor is facing

outwards and that reference marks are aligned.

10. Lubricate new cover plate sealing ring with

clean engine oil.

11. Fit cover plate seal and cover plate.

12. Apply sealant, Part No. STC 50552 to threads

of Torx screws, fit and tighten screws.

13. Check that pump rotates freely.

Refit

1. Fit oil pump gasket.