Freelander Service Procedures

ENGINE - K SERIES KV6

OVERHAUL 12-3-113

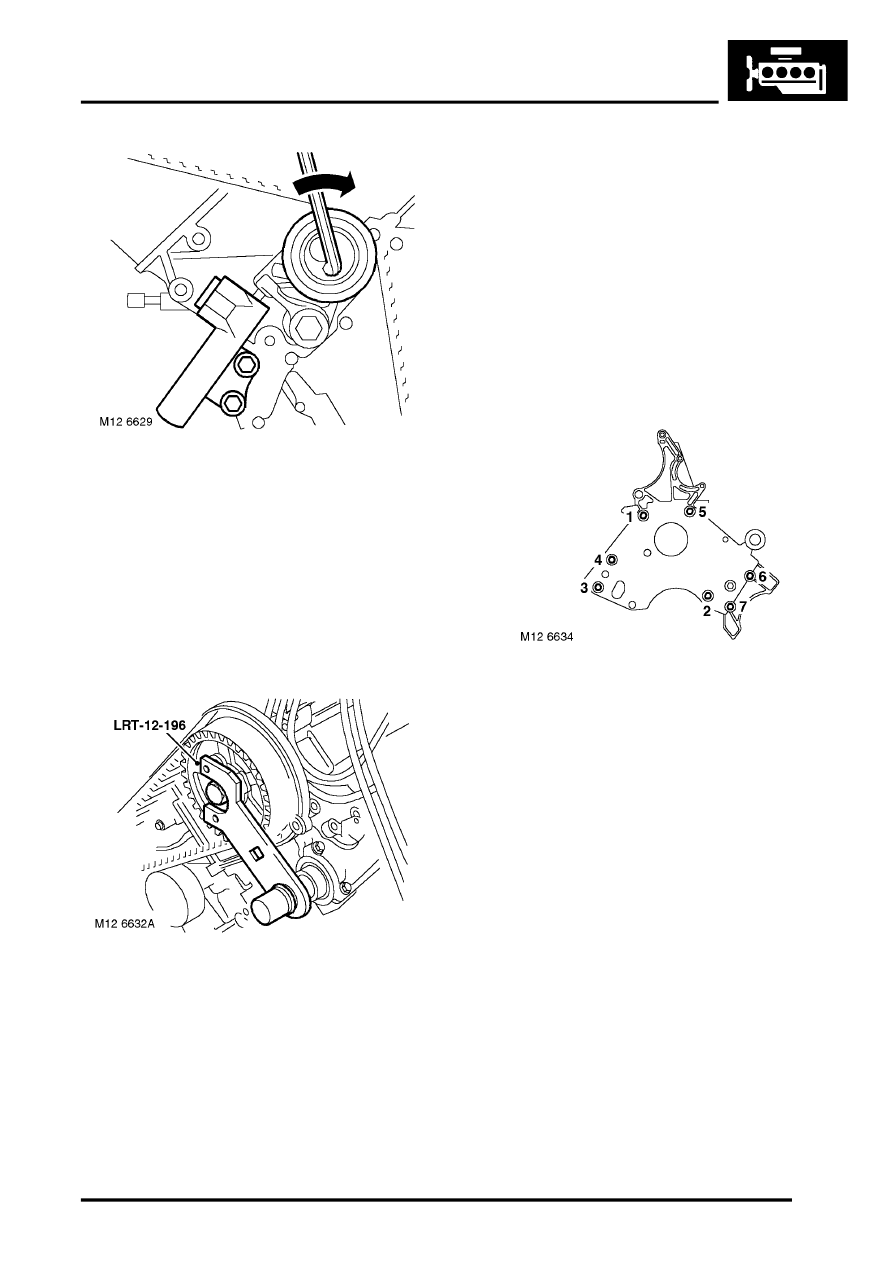

11. Position an Allen key in tensioner backplate

and hold tensioner pulley against timing belt.

12. With assistance, position timing belt tensioner,

fit new Patchlok bolts and tighten to 25 Nm (18

lbf.ft).

CAUTION: Ensure tensioner plunger is

contacting underside of tensioner

backplate.

13. Remove tools LRT-12-175 from rear timing belt

gears.

14. Fit tools LRT-12-196 to both front inlet

camshaft gears and into the end of each

exhaust camshaft.

CAUTION: Special tools must be fitted when

tightening or loosening gear retaining bolts,

otherwise damage to camshafts may occur.

15. Tighten front inlet camshaft gear bolts to:

l

Stage 1 - 27 Nm (20 lbf.ft)

l

Stage 2 - Further 90

°

16. Remove tools LRT-12-196 from both inlet

camshaft gears and exhaust camshafts.

17. Remove wedge from between drive belt and oil

pump belt guard.

18. Remove 1.5 mm diameter pin from tensioner.

19. Clean exhaust camshaft front cap seal

locations and fit new cap seals.

CAUTION: The sealing edge of the cap seal

and mating face must be clean and dry.

20. Position engine front mounting plate and

manoeuvre plate into position; fit bolts but do

not tighten at this stage.

21. Fit bolts securing IRD support bracket to front

mounting plate; do not tighten bolts at this

stage.

22. Tighten bolts in the sequence shown:

l

M10 bolt - No.1 - 25 Nm (18 lbf.ft)

l

M10 bolt - No. 5 - 45 Nm (33 lbf.ft)

l

Bolts Nos. 2, 3, 4, 6 and 7 - 85 Nm (63 lbf.ft)

23. Position engine lifting bracket, fit bolts securing

lifting bracket and front mounting plate to

cylinder block and RH cylinder head and

tighten to:

l

M8 bolt - 25 Nm (18 lbf.ft)

l

M10 bolts - 45 Nm (33 lbf.ft)

24. Fit rubber blanking plug around tensioner.

25. Clean end of dipstick tube.

26. Position dipstick tube to sump and cylinder

block, fit bolt and tighten to 9 Nm (7 lbf.ft).

27. Clean lower timing belt cover.

28. Position lower timing belt cover, fit and tighten

bolts to 9 Nm (7 lbf.ft).

29. Remove timing pin LRT-12-232.

30. Clean crankshaft pulley.

31. Fit crankshaft pulley to crankshaft gear and

ensure that the indent on pulley locates over

the lug on crankshaft gear.

32. Fit crankshaft pulley bolt and washer, position

LRT-12-161 with LRT-12-199 into crankshaft

pulley. Tighten pulley bolt to 160 Nm (118

lbf.ft).

33. Remove tools LRT-12-161 and LRT-12-199.

34. Clean ancillary drive belt tensioner.