Freelander Service Procedures

HOOD

76-7-6

REPAIRS

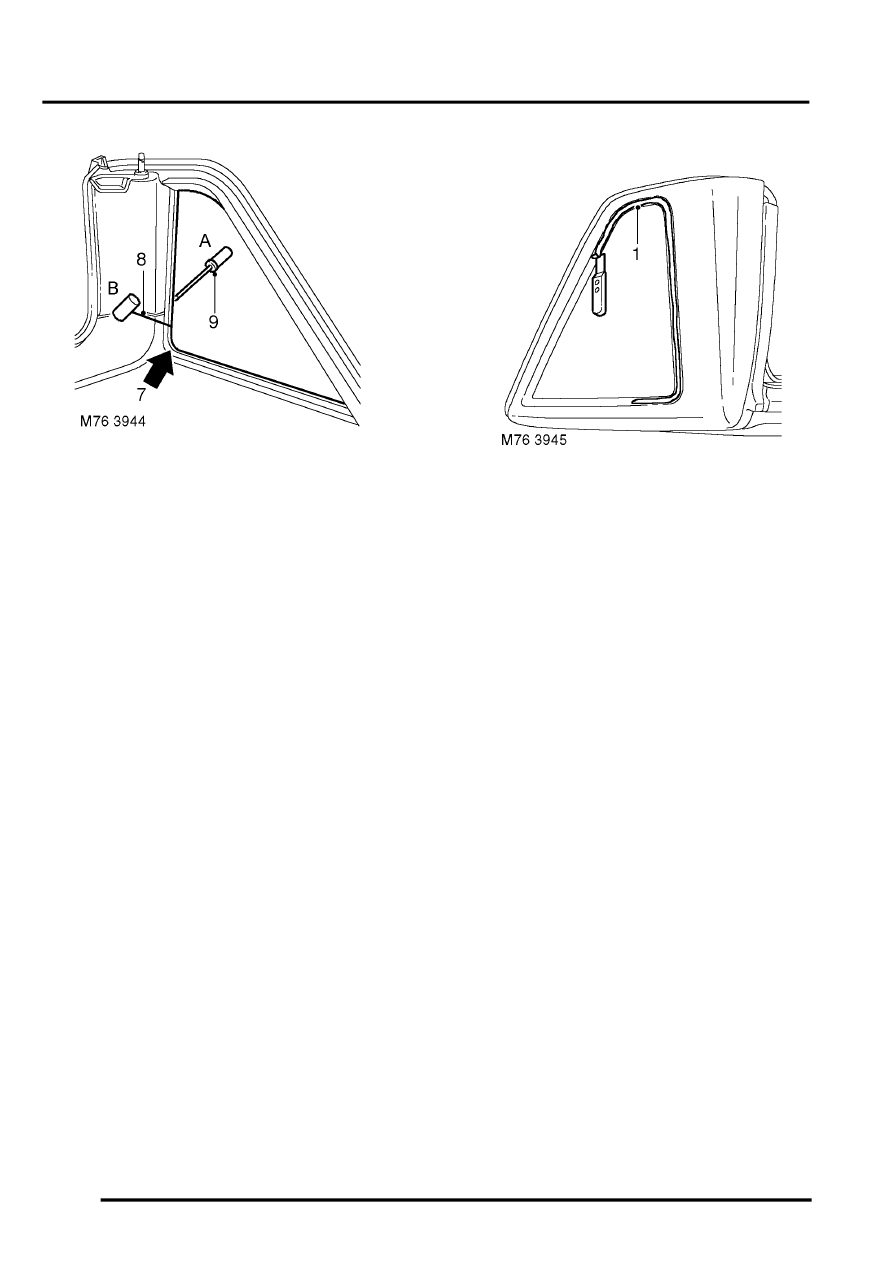

7. Make knife cut in sealant at bottom of 'E' post.

8. Insert cutting wire through previously made

knife cut and fit handles as shown, with

approximately 200 mm of wire between

handles.

9. With assistance, wedge tube of handle A

between glass and body, ahead of cutting

position, and carefully cut sealer using a

continuous pull on handle B from the outside.

Ensure that glass is retained as last sealant is

cut.

If multi-strand cutting wire is used, a sawing

action can be used to cut through heavy

sealant deposits around corners.

Use of a sawing action may overheat and

break single strand wire.

10. Attach suction cup and remove glass body.

Lay glass on felt covered supports. Do not

stand on edge. Any chipping of glass edge

may develop into cracks.

Refit

1. Carefully remove excess sealer from body

leaving a smooth surface.

2. Use a vacuum cleaner to clear away any waste.

3. Original glass: Carefully cut back old sealant to

obtain a smooth surface without damaging

obscuration band on glass.

4. With assistance, locate glass to body.

5. Apply masking tape reference marks to aid

fitment.

6. Remove glass and place aside.

7. Clean frame and edge of glass with solvent.

Do not touch cleaned or primed surfaces

with fingers.

8. Repair any damaged paintwork as necessary.

9. Apply bonding agent to glass and allow to cure.

10. Apply activator over old sealer on frame.

11. Allow activator to cure.

12. Apply primer to frame.

13. Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals, and install in applicator

gun.

Nozzle will need modification to achieve

required bead section.