Freelander Service Procedures

HOOD

REPAIRS

76-7-7

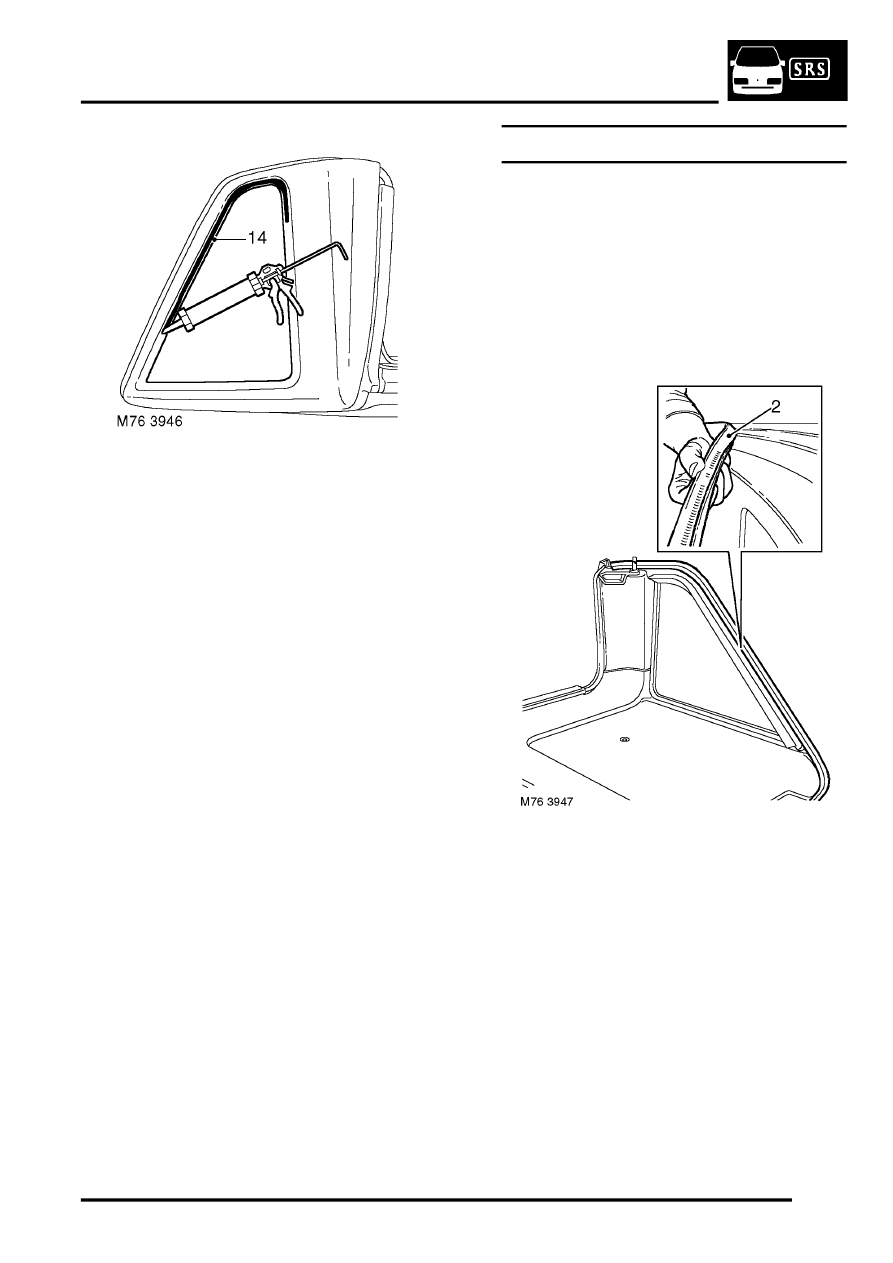

14. Apply a continuous bead of sealer around edge

of frame as shown. Make bead slightly thicker

at each corner.

15. Check for breaks and air bubbles in sealer.

16. Position glass to body and align to reference

tape.

17. Lightly press glass to fully seat sealer.

18. Secure glass with tape until sealer has cured.

19. Remove protective covers and tape.

20. Test seal for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Dry affected area and apply

additional sealer if necessary.

21. Position headlining and locate hardback seal.

22. Secure headlining with Torx screws.

23. Position catches, fit Torx screws and tighten to

10 Nm (7.5 lbf.ft).

24. Fit 'E post finishers, engage in clips and secure

with screws.

cover - assembly - remove for access & refit.

Seal - hard back - primary

$% 76.61.34

Always position trim components on a soft

covered, clean work surface.

Remove

1. Remove hard back.

cover - assembly - remove for access & refit.

2. Release seal from flange around hard back

frame and remove seal.

Refit

1. Clean seal flange.

2. Position seal and secure to flange.

3. Secure ends of seal to hard-back frame using

Butyl Rubber adhesive if necessary.

4. Fit hard back.