Range Rover P38

19

FUEL SYSTEM

NEW RANGE ROVER

10

REPAIR

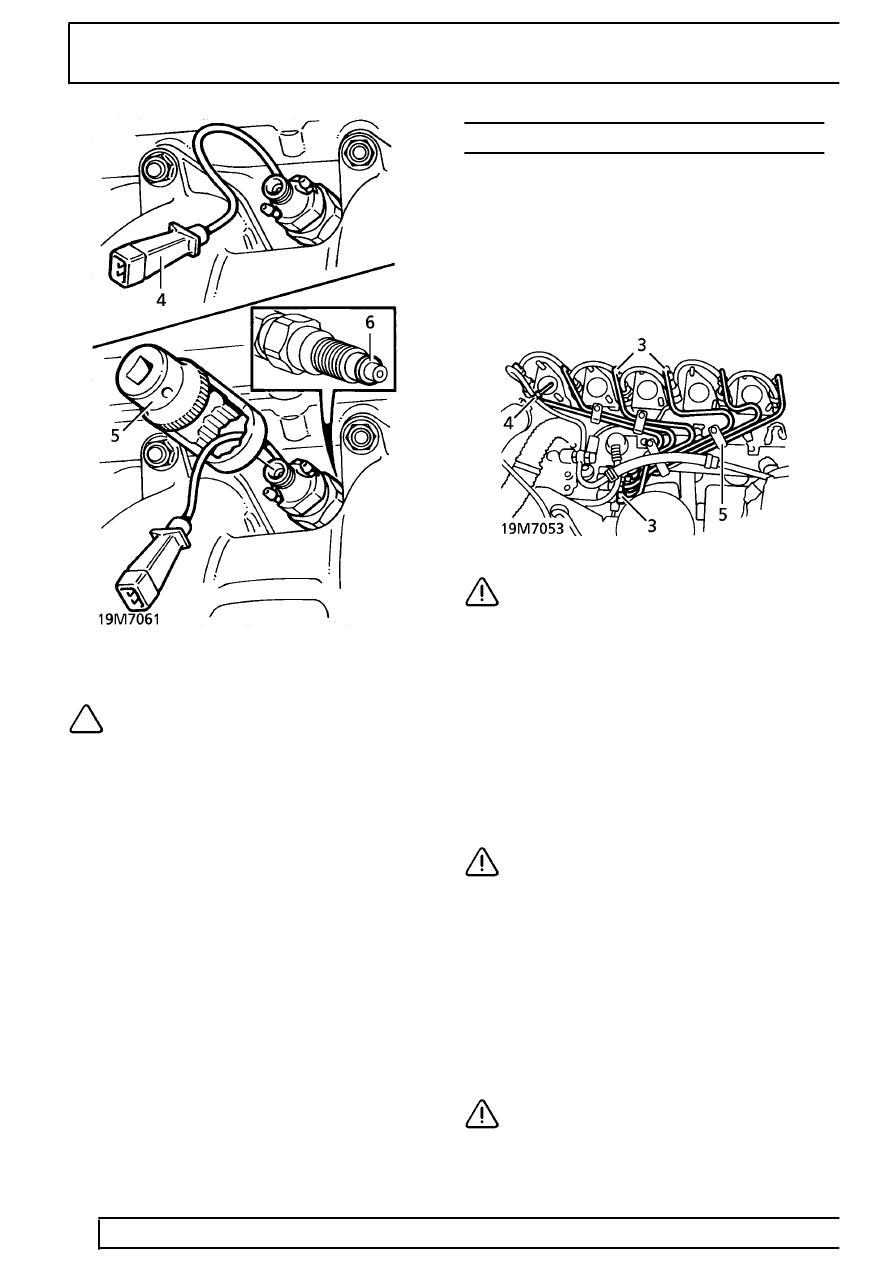

5. Remove injector using tool LRT-12-120.

NOTE: Special tool has cut-out for needle

lift sensor multiplug. Thread flylead

through tool. Ensure lead and connector

are not damaged during injector removal or

refitting.

6. Collect sealing washer and discard.

Refit

7. Ensure injector nozzle and cylinder head bore

are clean.

8. Apply anti-seize compound to injector threads.

9. Position injector with new sealing washer to

cylinder head. Using LRT-12-120. Tighten to

65

Nm (48 lbf.ft)

10. No. 4 injector only: Connect needle lift sensor

multiplug.

11. Remove plugs. Connect leak-off pipes.

12. Fit high pressure pipe assembly.

See this

section.

13. Reconnect battery negative lead.

HIGH PRESSURE PIPES

Service repair no - 19.60.14

Remove

1. Disconnect battery negative lead.

2. Remove inlet manifold.

See MANIFOLD AND

EXHAUST SYSTEM, Repair.

3. Using LRT-12-117, disconnect high pressure

pipes at Fuel Injection Pump (FIP) and injectors.

CAUTION: Hold delivery valves against

rotation as pipe unions are loosened.

4. Remove clip securing leak-off pipe to No. 1 high

pressure pipe.

5. Remove high pressure pipe assembly.

6. Plug high pressure pipes and connections.

Refit

7. Ensure all pipes and connections are clean,

8. Remove plugs. Position pipe assembly.

9. Using LRT-12-117, secure high pressure pipes

to injection pump. Tighten to

22 Nm (16 lbf.ft)

CAUTION: Hold delivery valves against

rotation as pipe unions are tightened.

10. Connect pipes to injectors. Do not tighten.

11. Secure leak-off pipe to No. 1 high pressure pipe

with clip.

12. Fit inlet manifold.

See MANIFOLD AND

EXHAUST SYSTEM, Repair.

13. Reconnect battery negative lead.

14. With assistance, crank engine. As fuel emerges

at injector connections, secure each pipe union

using tool LRT-12-117. Tighten to

22 Nm (16

lbf.ft)

CAUTION: Engine will start during high

pressure pipe bleeding procedure.