Montero V6-3.8L SOHC (2005)

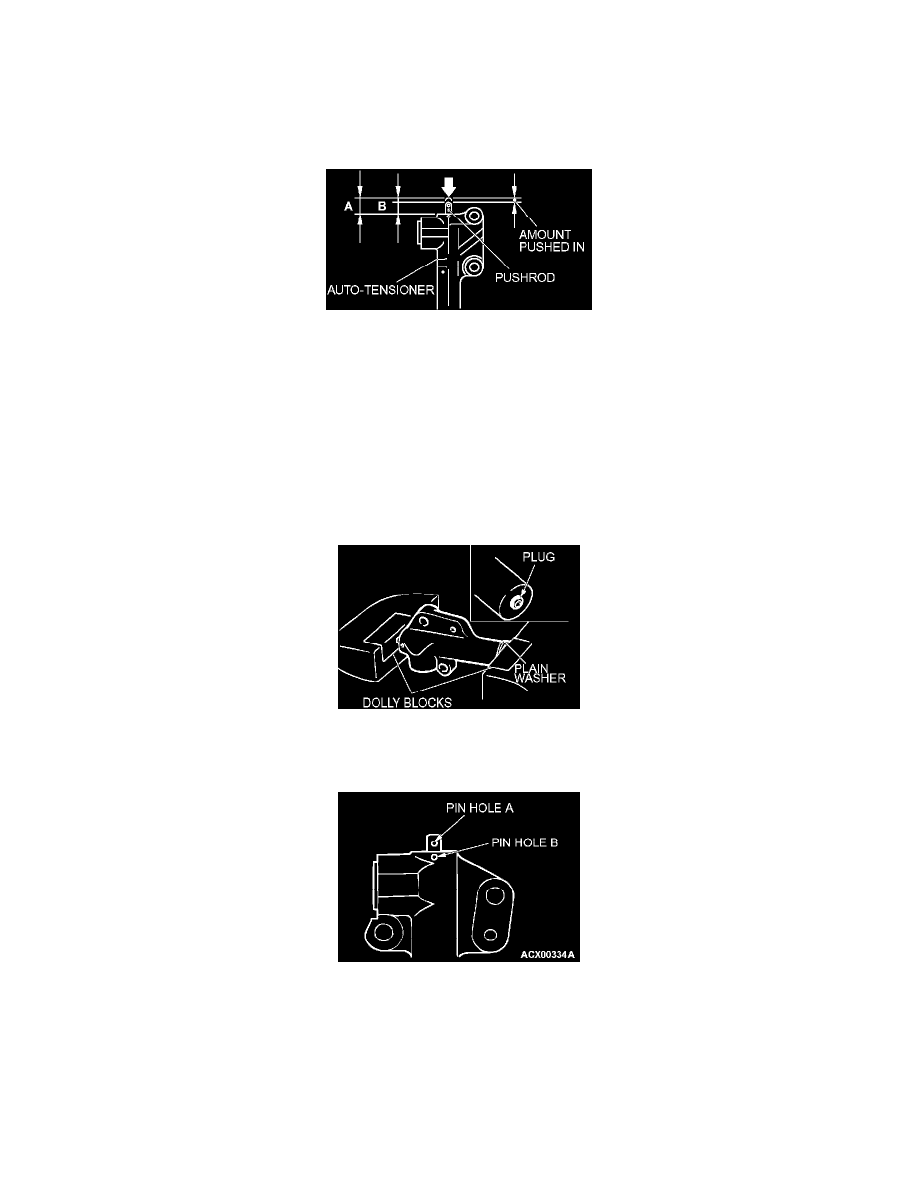

9. Wait for at least five minutes, and then check that the auto-tensioner pushrod extends within the standard value.

Standard value (A): 4.8 - 5.5 mm (0.19 - 0.22 inch)

10. If no, repeat the operation in steps (5) to (9) above.

11. Check again that the timing marks of each sprocket are aligned.

>>B<< AUTO-TENSIONER INSTALLATION

1. While holding the auto-tensioner by hand, press the end of the pushrod against a metal surface (such as the cylinder block) with a force of 98 -

196 N (72 - 145 pound) and measure how far the pushrod is pushed in.

Standard value: Within 1 mm (0.04 inch)

A: Length when no force is applied

B: Length when force is applied

A - B: Amount pushed in

CAUTION:

^

Place the auto-tensioner perpendicular to the jaws of the vice.

^

If there is a plug at the base of the auto-tensioner, insert a plain washer onto the end of the auto-tensioner to protect the plug.

2. If it is not within the standard value, replace the auto-tensioner.

3. Place two dolly blocks in a vice as shown in the illustration, and then place the auto-tensioner in the vice.

CAUTION: Never compress the pushrod too fast, or the pushrod may be damaged.

4. Slowly compress the pushrod of the auto-tensioner until pin hole A in the pushrod is aligned with pin hole B in the cylinder.

5. Insert the setting pin into the pin holes once they are aligned.

NOTE: If replacing the auto-tensioner, the pin will already be inserted into the pin holes of the new part.

CAUTION: Do not remove the setting pin from the auto-tensioner.

6. Install the auto-tensioner to the engine.

>>C<< CRANKSHAFT PULLEY INSTALLATION