| t

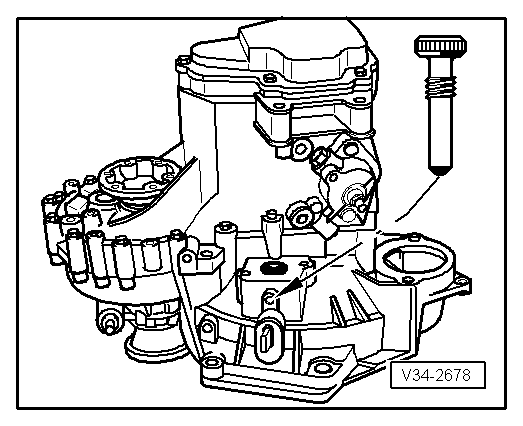

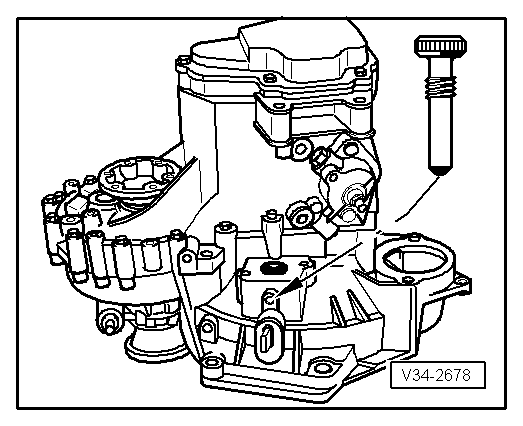

| If the gearbox has to be changed, the following must be reused in the new box: the speedometer sender, the selection rod, and the coupling lever. |

| –

| Clean input shaft splints and lightly grease with -G 000 100-. |

| –

| It must be possible to move the clutch plate from side to side on the input shaft. |

| –

| Check that the gearbox/engine dowel pegs are fitted to the engine, if not, fit them. |

| –

| Make sure the intermediate plate is correctly seated on the engine base. |

| –

| Centre the drive train group to place it in the installation position. |

| –

| Install the gearbox unit in the engine, free of tension, positioning it by jerking. |

| –

| Partially fit two bolts that secure the engine to the gearbox. |

| –

| Install in reverse order. |

| –

| Adjusting the gear drive mechanism → Chapter |

Note! | t

| On fitting the gearbox make sure that the input shaft and the adjustment bushes are correctly located. |

| t

| Do not withdraw special support tool -U-30025B-. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!