| –

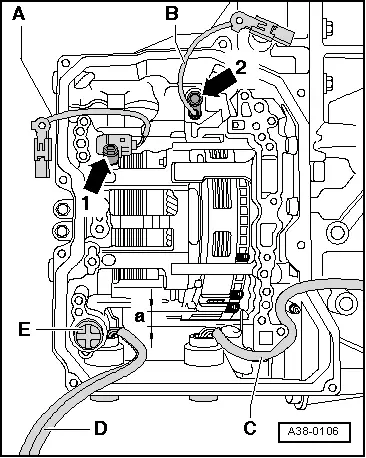

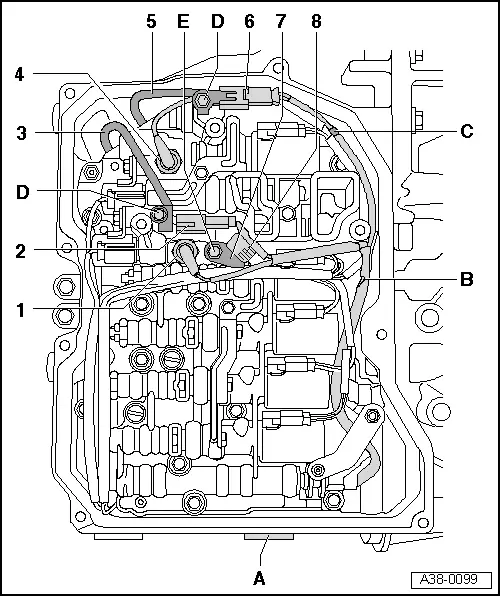

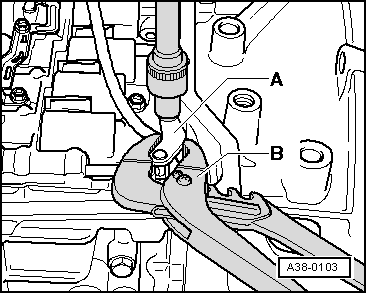

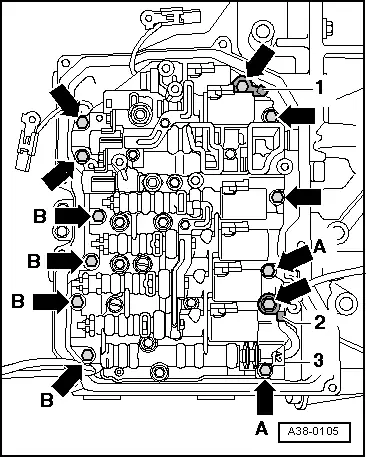

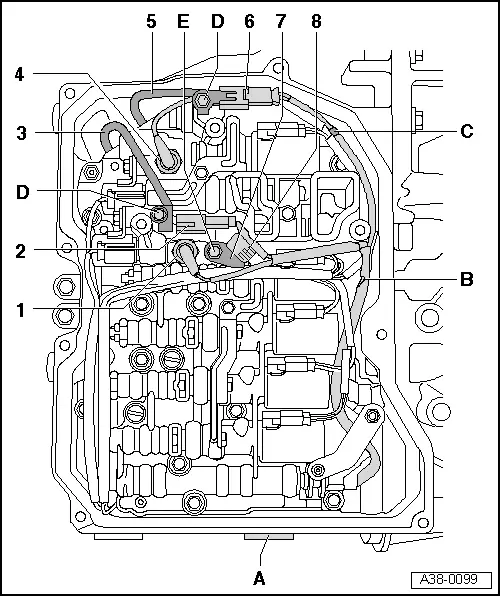

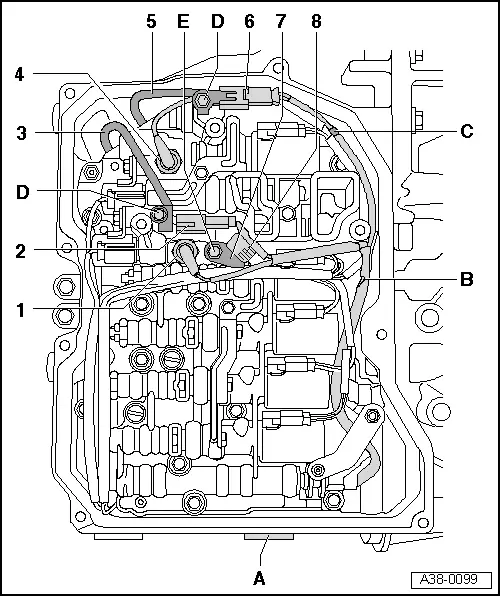

| Layout the cable harness -C- (with the 8 pin connector) as shown in the illustration, in the curves designed for this in the selector housing. |

| l

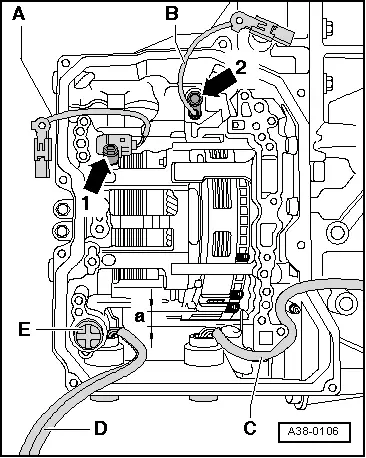

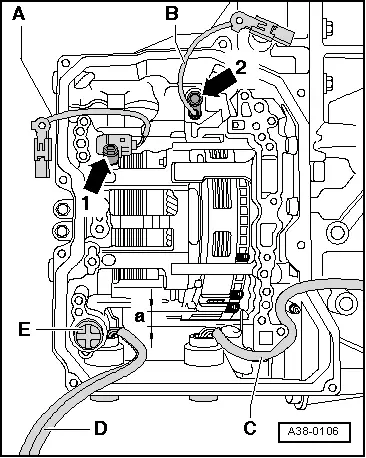

| The cable harness -C- should not come into contact with the planetary gears. The free space -a- must be preserved so that the cable harness is not grazed while driving. |

| –

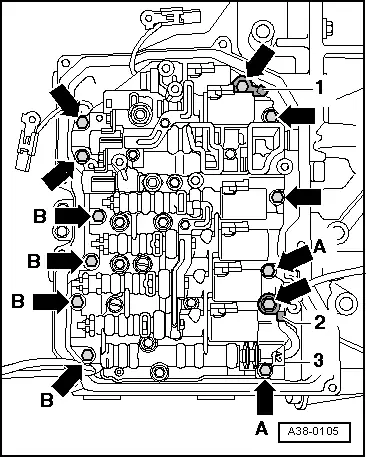

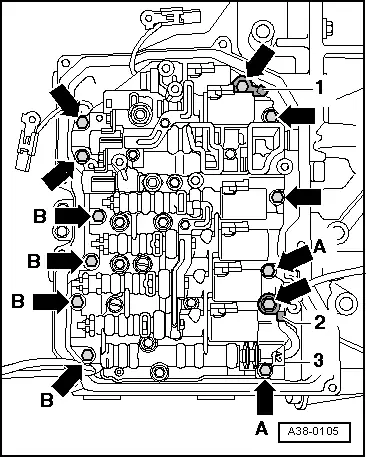

| Layout the cable harnesses -A-, -B- and -D-, as shown in the illustration, over the edge of the gearbox. |

| –

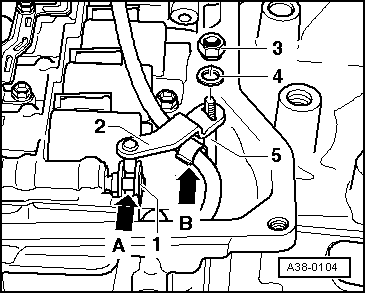

| Ensure that the damper cylinder -E- is fitted in the gearbox in the position shown by the illustration. |

Note | t

| If the damper cylinder -E- has been removed, it must be cleaned along with the two springs and fitted in a similar fashion → Item, → Item, → Item. |

| t

| To do this, the springs must be inserted into each other; smear the outer wall of the damper cylinder and the opening in the gearbox with ATF and then insert all parts into the gearbox. |

| t

| If necessary, keep the damper cylinder pressed into the gearbox (so it does not fall out) until the selector gear has been secured. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

WARNING

WARNING