Leon Mk1

| Removing and installing oil seals for front right flange shaft and front right bevel gear with stub shaft |

| Special tools and workshop equipment required |

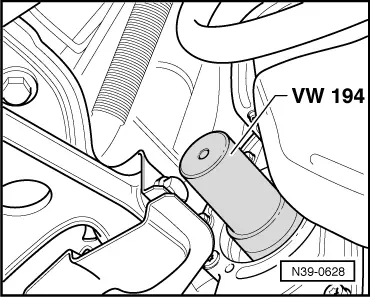

| t | Drift sleeve -VW 194- |

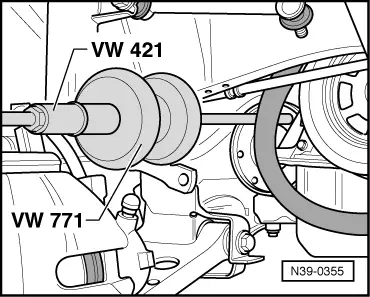

| t | Tube -VW 421- |

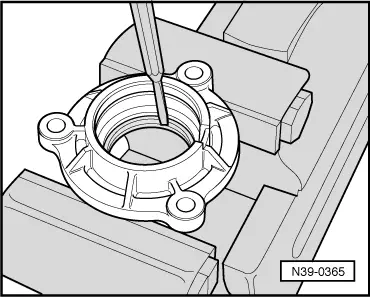

| t | Multi-purpose tool -VW 771- |

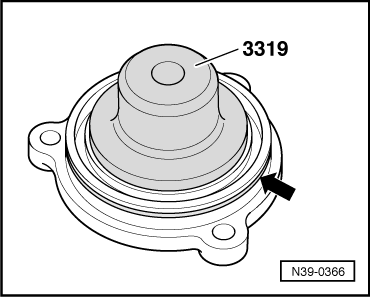

| t | Pressure piece -3319- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

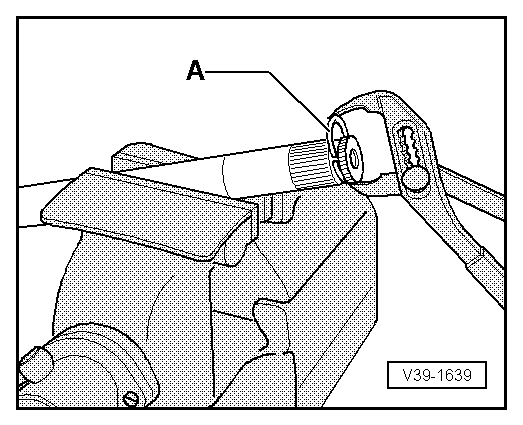

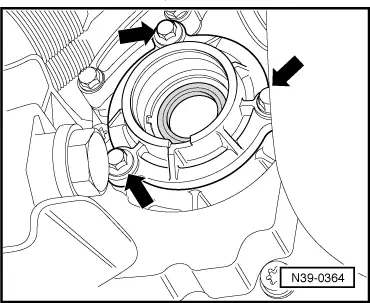

| Cover on bevel box | 25 Nm | ||

| Drive shaft to drive flange | 80 Nm | ||

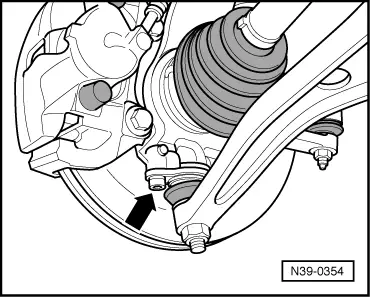

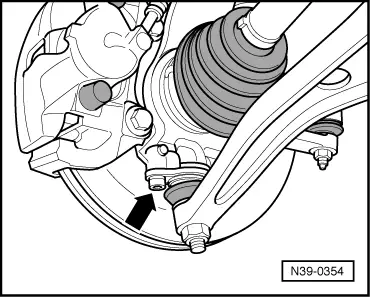

| Wheel bearing housing to lower swivel joint | 55 Nm | ||

Hexagon bolt on drive shaft

| 150 Nm + 90° | ||

| Coupling rod on anti-roll bar | 100 Nm | ||

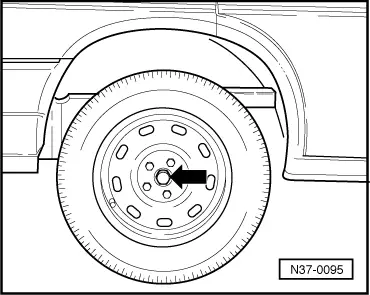

| Wheel bolts to wheel hub | 140 Nm |