Leon Mk1

|

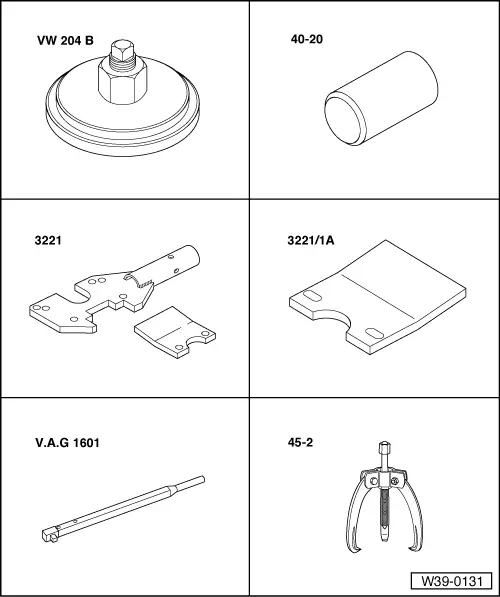

| Special tools and workshop equipment required |

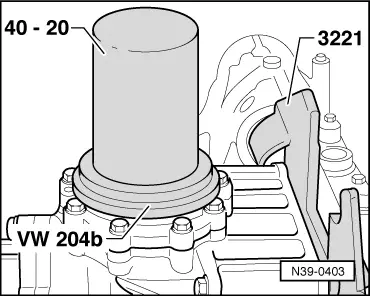

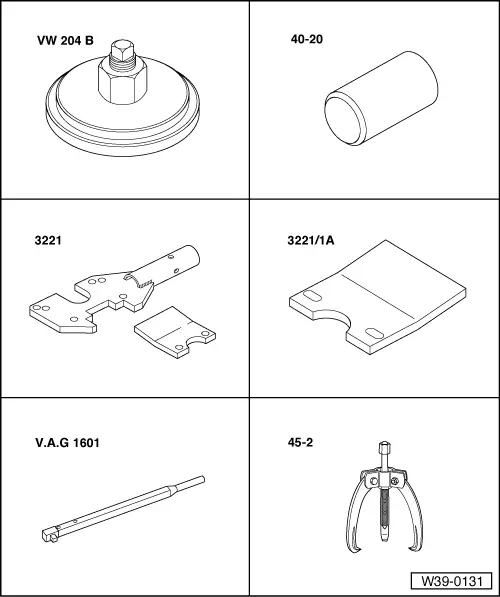

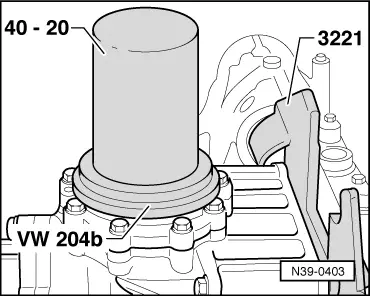

| t | Crankshaft seal insertion tool -VW 204 B- |

| t | Drift sleeve -40 - 20- |

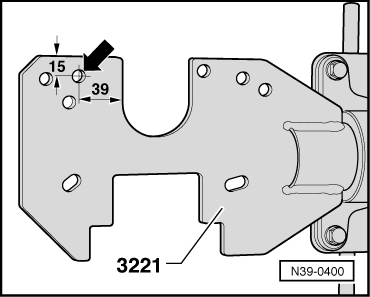

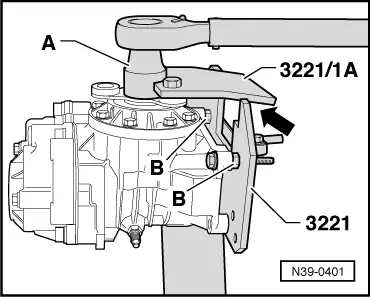

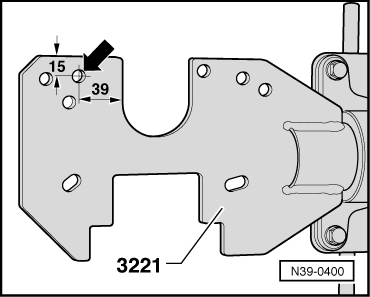

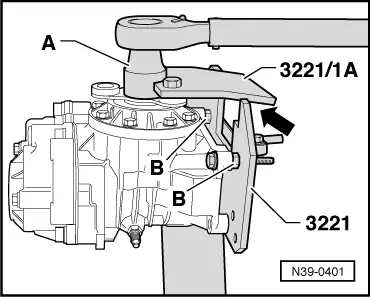

| t | Gearbox support -3221- |

| t | Support plate -3221/1A- |

| t | Torque wrench -V.A.G 1601- |

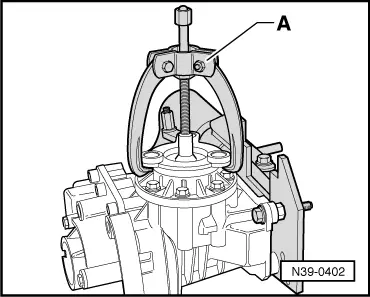

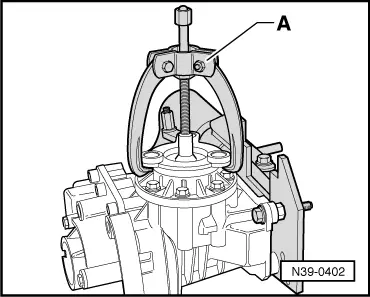

| t | Three arm puller -Kukko 45-2- |

|

|

|

|

|

|

|

|

|

|

| Special tools and workshop equipment required |

| t | Crankshaft seal insertion tool -VW 204 B- |

| t | Drift sleeve -40 - 20- |

| t | Gearbox support -3221- |

| t | Support plate -3221/1A- |

| t | Torque wrench -V.A.G 1601- |

| t | Three arm puller -Kukko 45-2- |

|

|

|

|

|

|

|

|

|