Leon Mk1

|

|

|

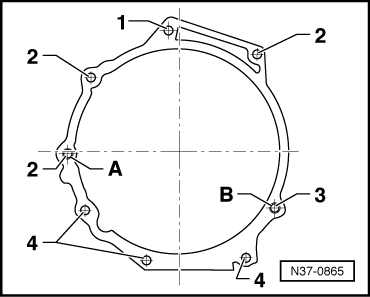

| Item | Bolt | Quantity | Nm |

| 1 | M 12 x 40 | 1 | 80 |

| 2 | M 12 x 60 | 3 | 80 |

| 3 | M 12 x 70 | 1 | 80 |

| 4 | M 10 x 55 | 3 | 45 |

|

|

|

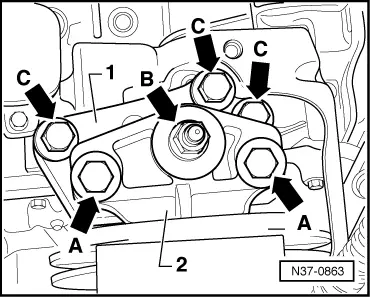

| Bolts -arrows A- | 90 Nm + 90° |

| Nut -arrow B- | 90 Nm + 90° |

| Bolts -arrows C- | 60 Nm + 90° |

|

|

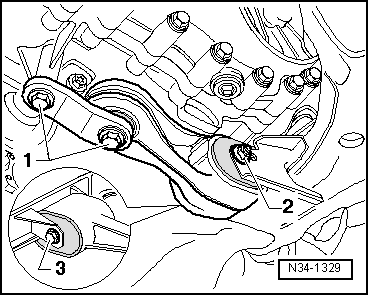

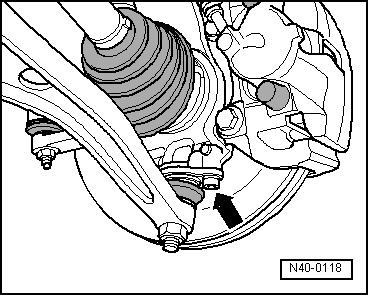

| Bolts -1- | 60 Nm + 90° |

| Nut -2- to bolt -3- | 100 Nm |

Note!

Note!

|

|

|

|

|