Leon Mk1

|

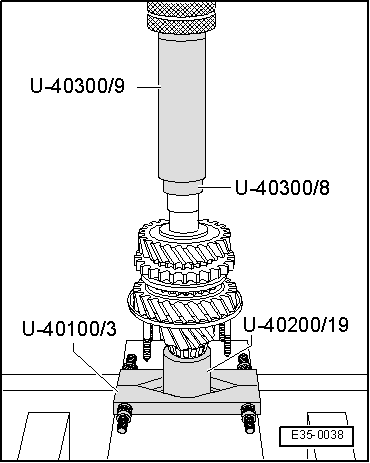

| Special tools and workshop equipment required |

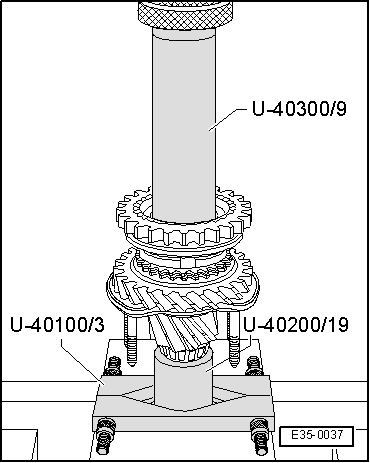

| t | Base -A-81124-, see equivalent → Anchor |

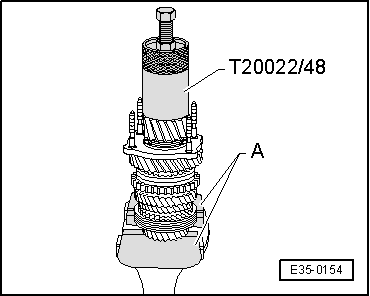

| t | Kit (case) -T20022-, see equivalent → Anchor |

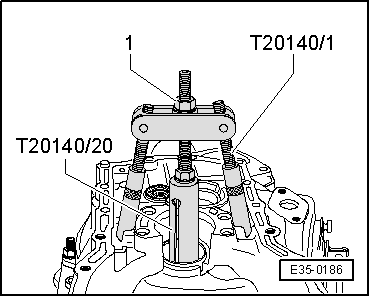

| t | Extractor kit -T20140-, see equivalent → Anchor |

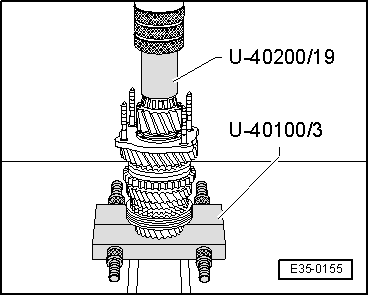

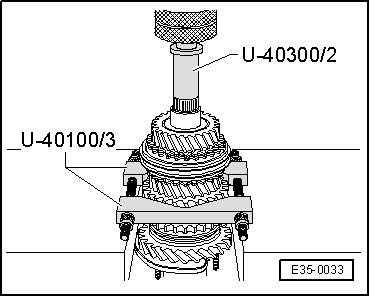

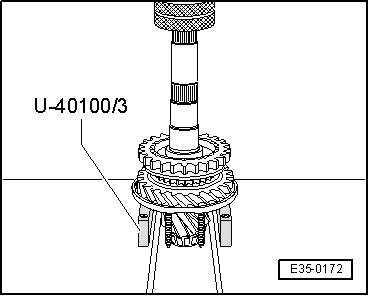

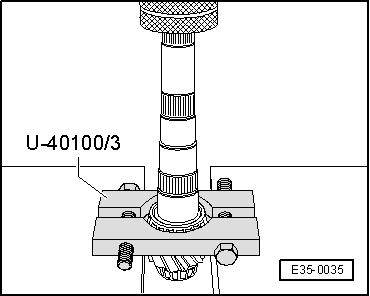

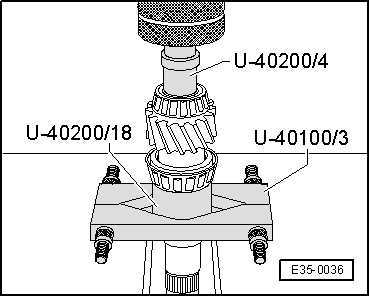

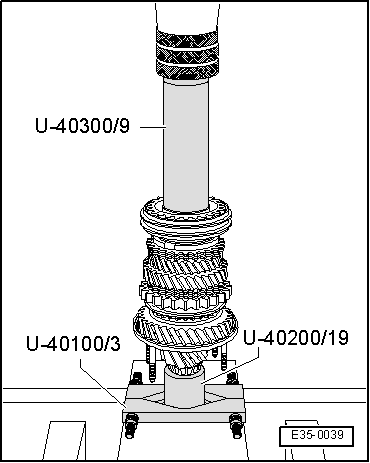

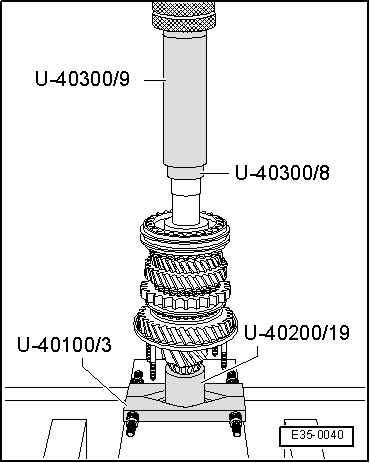

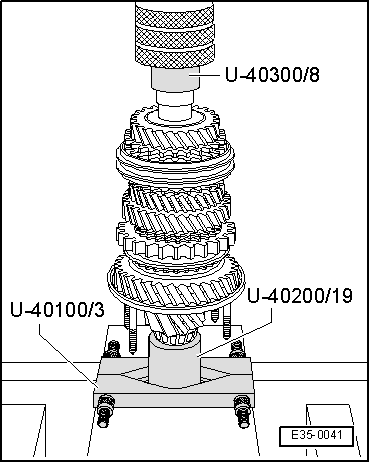

| t | Extractor kit -U 40100B-, see equivalent → Anchor |

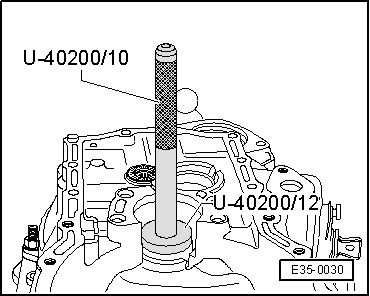

| t | Kit (case) -U 40200A-, see equivalent → Anchor |

| t | Kit (case) -U 40300-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

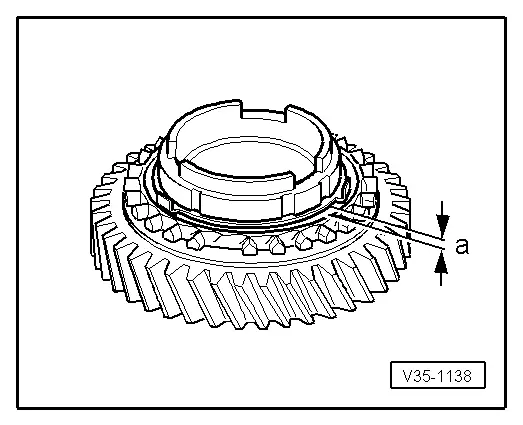

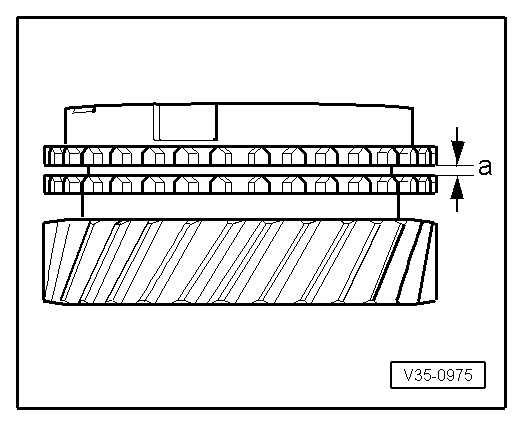

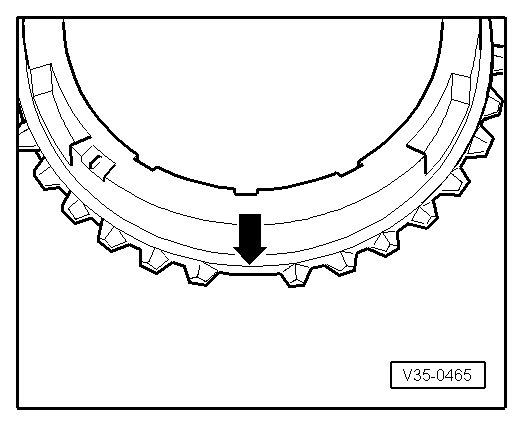

| Synchro-ring | Measurement „a“ in new synchro | Wear limit |

| 1st and 2nd gears | 0.75...1.25 mm | 0.3 mm |

|

|

| Synchro-ring | Measurement „a“ in new synchro | Wear limit |

| 1st and 2nd gears | 1.2 ... 1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

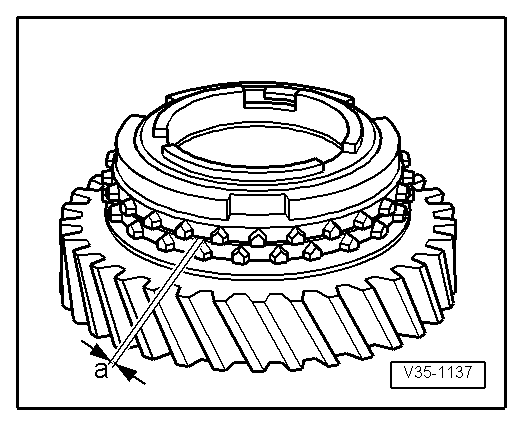

| Synchro-ring | Measurement „a“ in new synchro | Wear limit |

| 1st gear | ||

| 3rd gear | 1.0 ... 1.7 mm | 0.5 mm |

| 4. gear |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|