| t

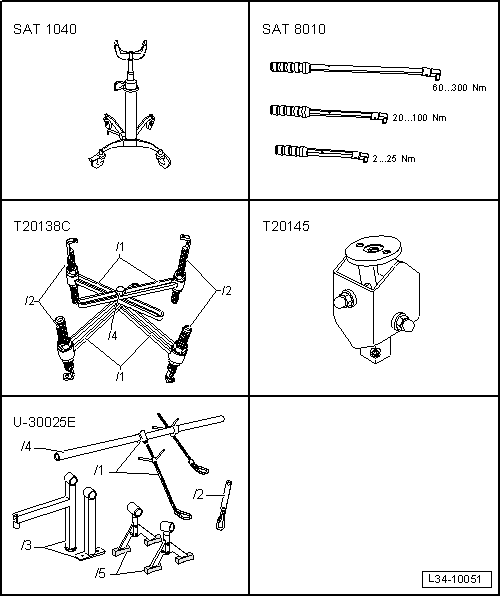

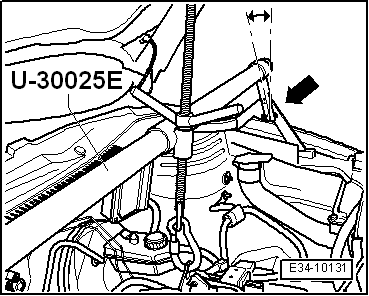

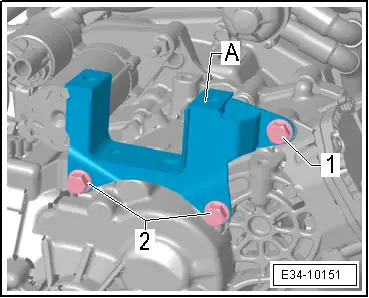

| Adapter for the hydraulic engine and gearbox jack -SAT 1001/1- |

Note | t

| Observe rules for cleanliness when working on gearbox → Chapter. |

| t

| Refer to general repair instructions → Chapter. |

| t

| Observe notes on dual clutch gearbox 0AM → Chapter. |

| t

| All cable ties which are released or cut open when removing the gearbox must be refitted in the same position when installing the gearbox. |

| –

| Raise the vehicle. In doing so, place the supports of the lifting platform at the same height. |

| –

| Put the gear selector lever into position »P«. |

| –

| With ignition switched off, disconnect battery earth strap. |

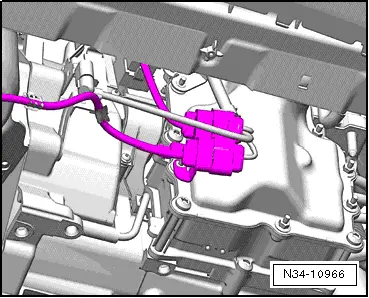

| Engine TSI, 1.4 l - 110 and 132 kW |

| Engine SRE, 1.6 l - 77 kW |

| –

| Remove the first intake manifold lower of the intake system. |

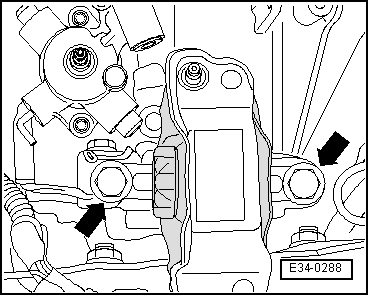

| All vehicles (continued): |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note