| –

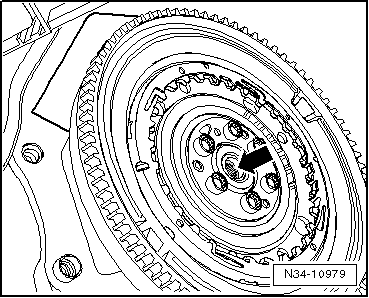

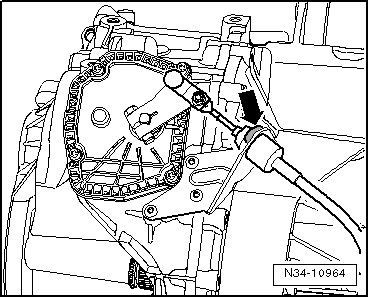

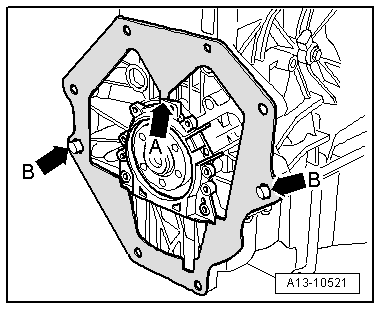

| The circlip of the selector lever cable must be replaced. |

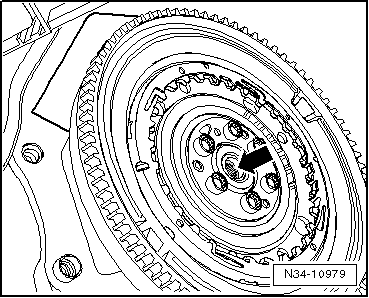

| A lock washer, which was removed, never insert again. It could be damaged if it no longer has the necessary inner tension. |

| –

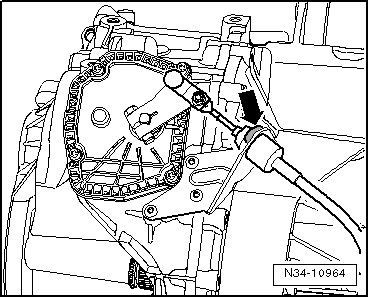

| Always adjust the selector lever cable → Chapter. |

| Engines 1.4 l - 110 kW TSI and 1.4 l - 132 kW TSI |

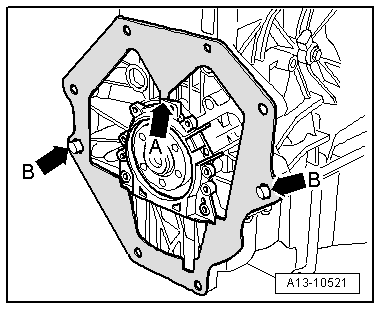

| All vehicles (continued): |

| Engine TSI, 1.4 l - 110 and 132 kW |

| Engine SRE, 1.6 l - 77 kW |

| –

| Fit the first intake manifold of the intake system. |

| All vehicles (continued): |

| –

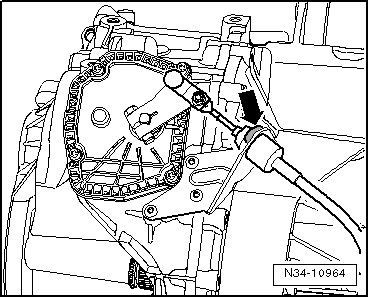

| Connecting the Vehicle diagnostic, testing and information system -VAS 505X- |

| –

| Perform the complete basic setting → Chapter. |

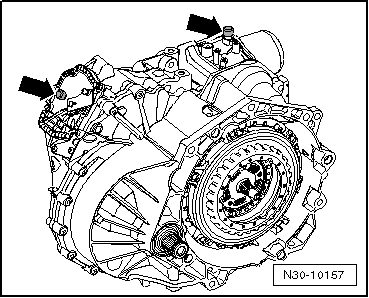

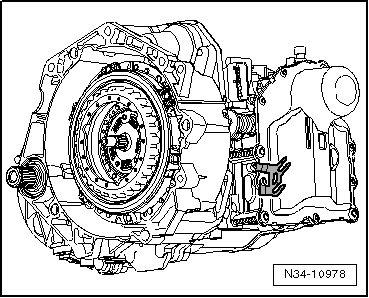

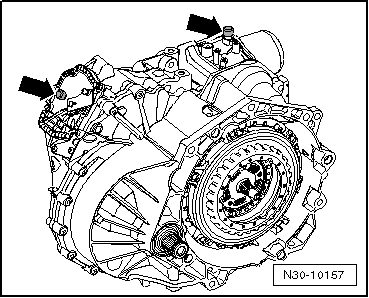

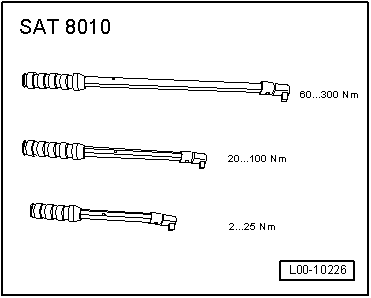

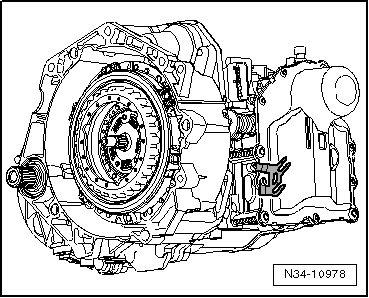

| Gearbox assembly mounting tightening torques → Chapter |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note